I. AGV Drive Layout Solution | Selecting the Most Suitable “Mobility” Method

Release time:

2025-09-02

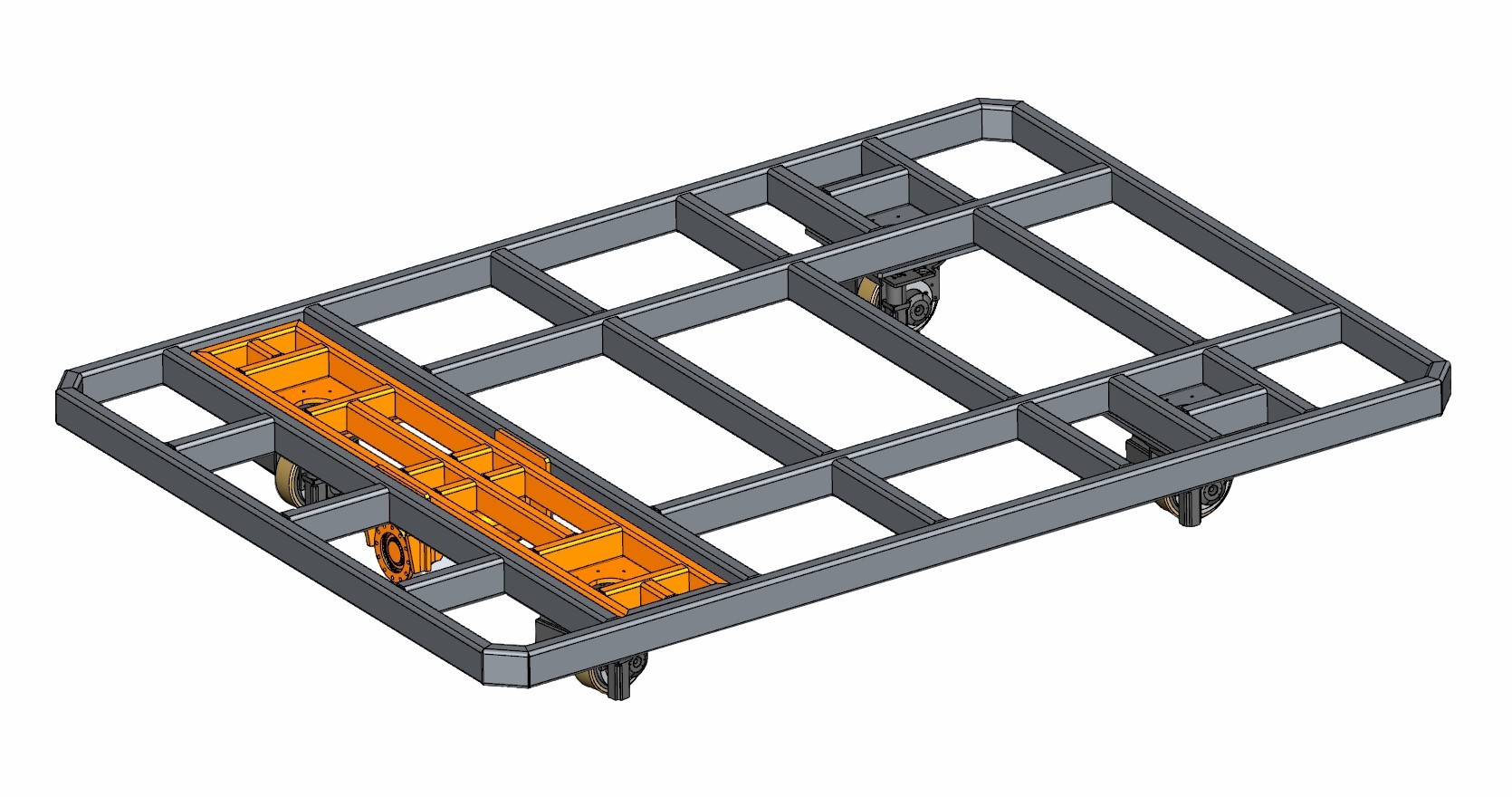

Automated Guided Vehicles (AGVs) serve as a core component of modern intelligent logistics and flexible manufacturing systems. Their “mobility” directly determines the efficiency, stability, and adaptability of the entire system. The “mobility” of AGVs—the core of their motion performance—stems from their drive configuration: the number, type, and spatial arrangement of drive units and steering units. Different drive configurations endow AGVs with distinctly different motion characteristics, such as agility, precision, load capacity, and cost. This article will delve into mainstream AGV drive layouts, helping you understand and select the optimal solution for specific application scenarios.

I. Core Components of Drive Layouts

AGV drive systems typically consist of two core components:

1. Drive Unit: Motors providing forward/reverse propulsion, usually integrated with reduction gearing and wheels.

2. Steering Unit: The mechanism controlling the AGV's direction, which can be an independent steering wheel or drive wheels that steer via differential action.

Various drive layouts emerge from the combination and arrangement of these two units.

II. Mainstream Drive Layouts and Their Characteristics

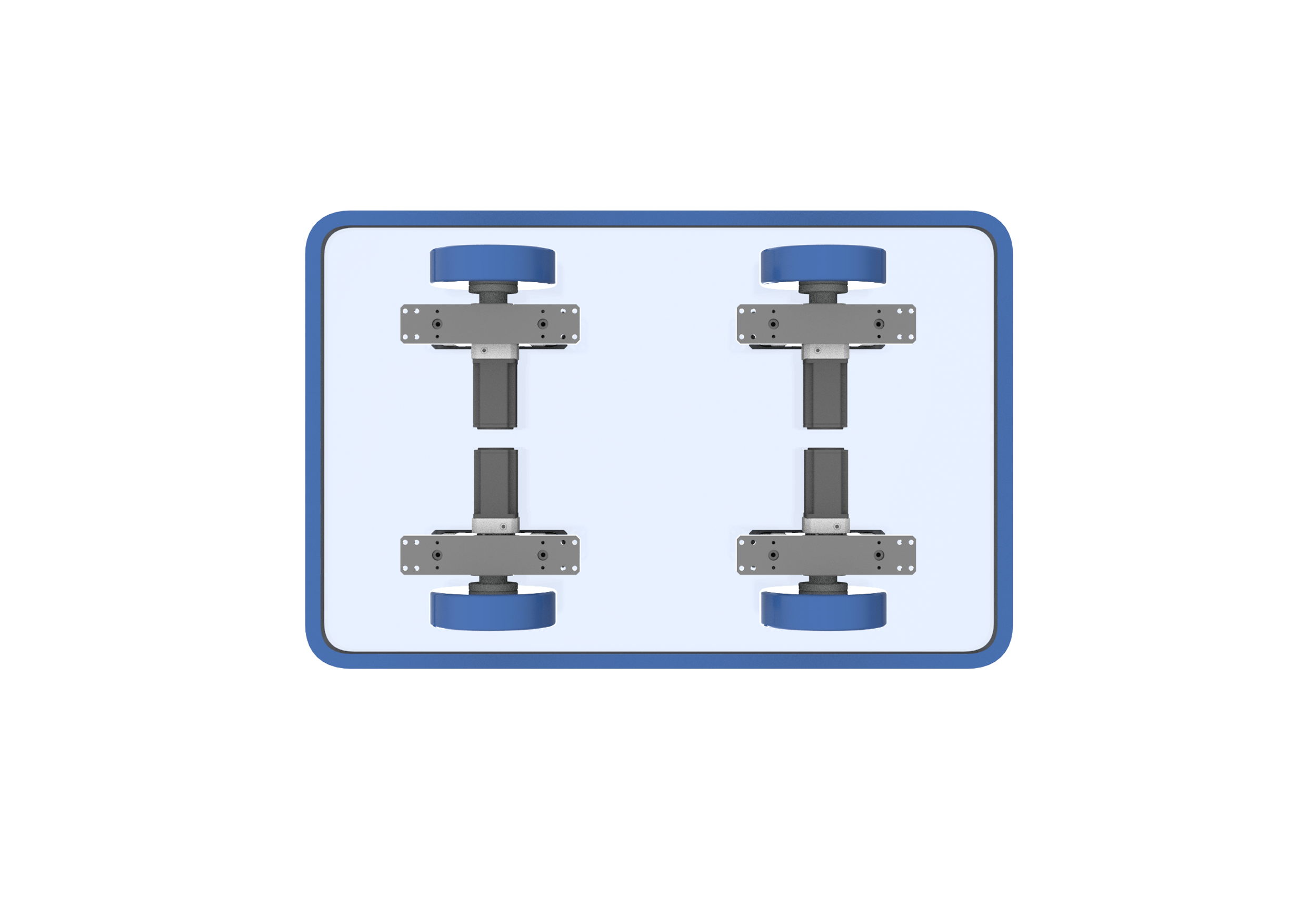

1. Differential Drive Layout

Structure: This is one of the most common and classic layouts.

Typically, two independently driven fixed wheels (drive wheels) are symmetrically arranged on both sides of the chassis, with one or more swivel casters (e.g., swivel wheels) positioned front and rear for support and assistance.

Working Principle: Precise control of the speed difference between the two drive wheels enables straight movement, turning, and even on-the-spot rotation. For example:

- Both wheels rotating at the same speed and direction: Straight movement

- One wheel faster than the other: Turning

- One wheel rotating while the other remains stationary: On-the-spot rotation

Advantages:

Simple structure, lower cost: Relatively straightforward mechanical design with mature control algorithms.

High flexibility: Capable of zero-turn-radius rotation, exceptionally agile in confined spaces.

Excellent path adaptability: No restrictions on path curvature.

Disadvantages:

Relatively low positioning accuracy: Errors may accumulate over extended operation due to tire wear or ground slippage.

Moderate load capacity: Primary weight-bearing and propulsion rely on two wheels, making it less suitable for heavy loads. High ground flatness requirements: Uneven surfaces may cause one wheel to lift and slip.

Application Scenarios: Widely used in e-commerce warehousing sorting, libraries, hospitals, and light assembly lines where high flexibility and moderate load capacity are required. Commonly found in scissor-lift AGVs and forklift-style AGVs.

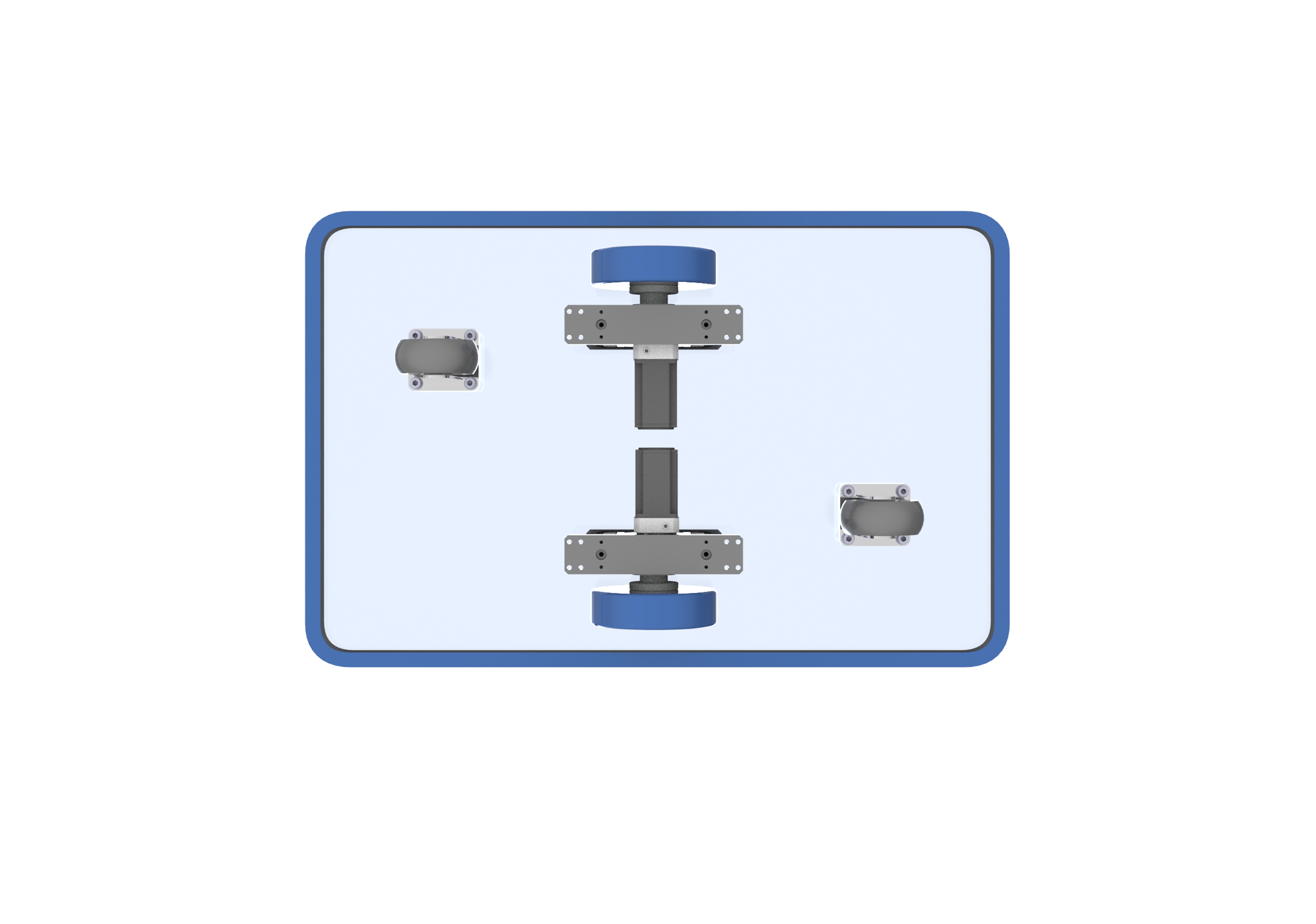

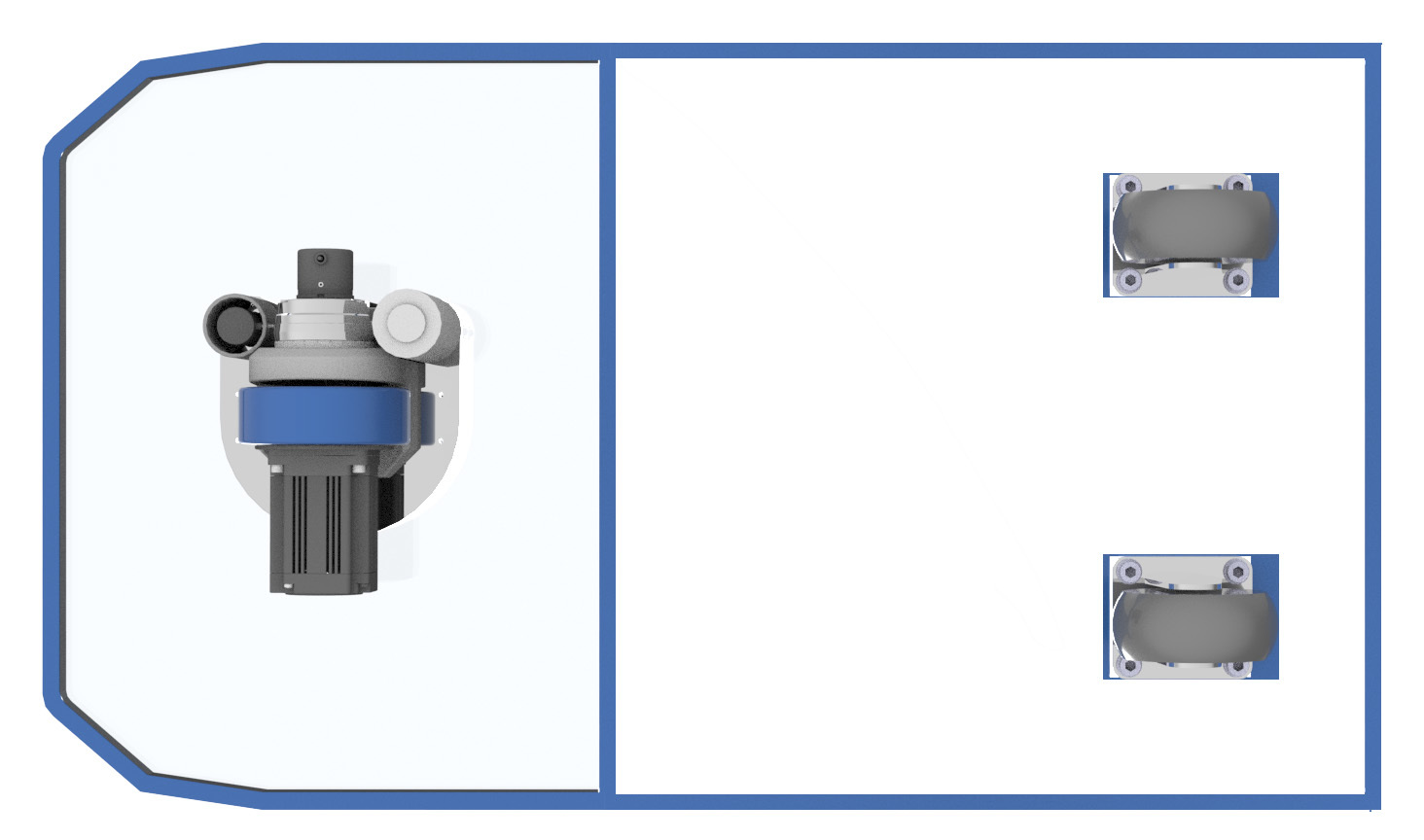

2. Single Steering Wheel Drive Layout

Structure: Typically features a powered steering wheel (combining drive and steering functions) as the core, paired with one or more swivel casters (wheels) for stable support.

Working Principle: The steering wheel actively turns ±90° (or wider angles) while providing propulsion. The AGV's direction is entirely determined by the steering wheel's orientation, similar to a car's steering wheel.

Advantages:

High Control Precision: Simple motion model enables exceptional line-following accuracy and docking precision.

Strong Load Capacity: Steering wheels are typically robustly designed to handle heavy-duty loads.

Stable Travel: Similar to automotive movement, it maintains exceptional stability during high-speed straight-line travel.

Disadvantages:

Large Turning Radius: Cannot perform on-the-spot turns, requiring ample turning space.

Limited Flexibility: Less agile than differential drive systems in complex, space-constrained paths.

Higher Cost: Steering wheels are precision components with manufacturing costs exceeding standard drive wheels.

Application Scenarios: Suitable for industrial settings with well-defined paths, demanding docking precision, and heavy loads. Examples include material handling on automotive assembly lines, heavy pallet transport, and container transfer. Commonly found in pallet-type AGVs and tow-type AGVs.

Related news

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct