Heavy-Duty Casters with Steering Motors: Core Equipment for Modern Logistics and Manufacturing

Release time:

2025-08-30

In modern workshop logistics systems, mobile robots as core equipment face challenges such as poor maneuverability and low positioning and navigation accuracy.

Existing mobile robots often cannot simultaneously change their position and direction, nor can they perform sideways or diagonal movement, severely limiting their application efficiency in complex environments.

In modern logistics, industrial manufacturing, and commercial applications, every movable piece of equipment relies on a seemingly simple yet crucial component—the caster wheel. Among these, the steering caster is undoubtedly the core element enabling flexibility and mobility. It is not merely a wheel mounted beneath equipment but the key that grants heavy objects “directional control” and “freedom of movement.”

I. Introduction: What is a Steering Caster?

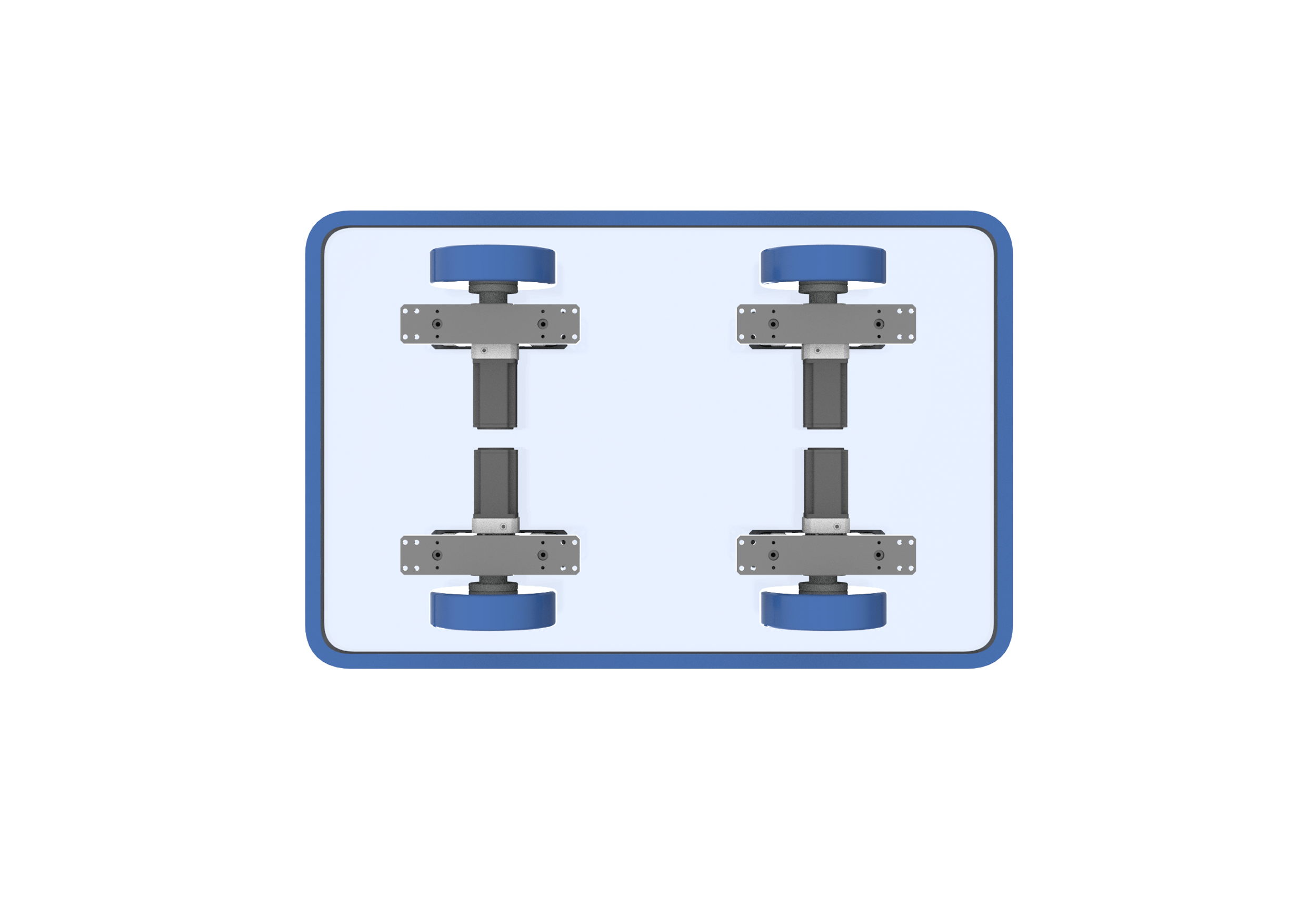

A steering caster typically consists of the following components:

Wheel: The load-bearing and rolling part, available in various materials (such as nylon, polyurethane, rubber, cast iron, etc.) to suit different surfaces and environments.

Fork: Also known as the “Swan Neck” or “Yoke,” this is the metal structure that secures the wheel and connects to the steering mechanism.

Top Plate: The main mounting structure for the equipment, usually featuring mounting holes.

Swivel Mechanism: The core component, typically incorporating a swivel bearing (ball or roller bearing) or swivel sleeve. This allows the fork and wheel to rotate 360 degrees around a vertical axis.

Brake System (Optional): Usually includes a directional brake (locks steering) and a wheel brake (locking the rolling function).

Its operation is simple yet efficient: when lateral force is applied to change the device's direction, the swivel mechanism responds, automatically aligning the wheels with the force direction to achieve smooth, fluid steering. This resembles the front wheels of a supermarket shopping cart—a gentle push sends it moving precisely where you intend.

II. Core Advantages: Why is Steering Functionality Indispensable?

The widespread adoption of swivel casters stems from their significant advantages:

1. Unparalleled Flexibility and Maneuverability

This is their fundamental strength. 360-degree free rotation enables equipment to effortlessly achieve:

Tight-radius turns or even pivoting on the spot: This is crucial for equipment navigating warehouse shelves, production lines, or hospital corridors.

Lateral movement: By strategically combining fixed and swivel casters, equipment can effortlessly slide sideways, significantly enhancing positioning accuracy and efficiency.

Obstacle avoidance: Quickly and flexibly navigating around barriers reduces collision risks and improves operational safety.

2. Reduced Operating Force and Physical Strain

The swivel caster design ensures wheels automatically align with the direction of movement, drastically reducing the force required to push or pull equipment. Operators need only apply a guiding force to turn the equipment effortlessly, without strenuous dragging. This not only boosts work efficiency but also significantly lowers operator fatigue and injury risks, adhering to ergonomic principles.

3. Protect Floors and Equipment

Smooth steering prevents harsh dragging and scraping. By reducing sliding friction resistance during turns, swivel casters effectively safeguard expensive flooring (e.g., epoxy surfaces, hardwood floors). Simultaneously, their fluid motion minimizes impact and vibration on the equipment itself and any precision cargo it carries.

4. Exceptional Load Capacity and Stability

Modern heavy-duty swivel casters utilize high-quality bearings (such as tapered roller bearings, precision ball bearings) and reinforced bracket designs to withstand loads ranging from several tons to tens of tons. Even under heavy loads, superior steering mechanisms ensure smooth turning without “dead spots” or jamming, guaranteeing stability and safety during heavy-duty movement.

5. Enhanced Functionality and Safety

Integrating various braking systems significantly expands the functionality of swivel casters:

Directional Brake: Locks the swivel function, converting the swivel wheel into a fixed wheel. This allows equipment to move only in a straight line, ideal for long-distance straight pushes or preventing accidental slippage on slopes.

Full Brake: Simultaneously locks both swivel and rolling functions, securely anchoring equipment in its working position.

Related news

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct