II. Technology Frontiers | Two Wheels or Four? Strategic Choices in AGV Drive Layout

Release time:

2025-09-04

II. Technology Frontiers | Two Wheels or Four? Strategic Choices in AGV Drive Layout

In today's era of rapid advancement in automated logistics and smart manufacturing, automated guided vehicles (AGVs) have become the indispensable “intelligent lifeblood” of modern factories and warehouses.

As the core system of AGVs, the choice of drive configuration directly impacts the efficiency, reliability, and return on investment of the entire material handling system. Among these decisions, the strategic choice between dual-steering-wheel drive and quad-steering-wheel drive is a critical consideration every AGV designer must thoroughly evaluate.

I. Fundamental Differences: More Than Just Doubling the Quantity

Many may assume that quad steering wheels are merely a simple numerical expansion of dual steering wheels. In reality, this represents a comprehensive upgrade spanning mechanical design to motion control.

1. A World of Difference in Mechanical Structure

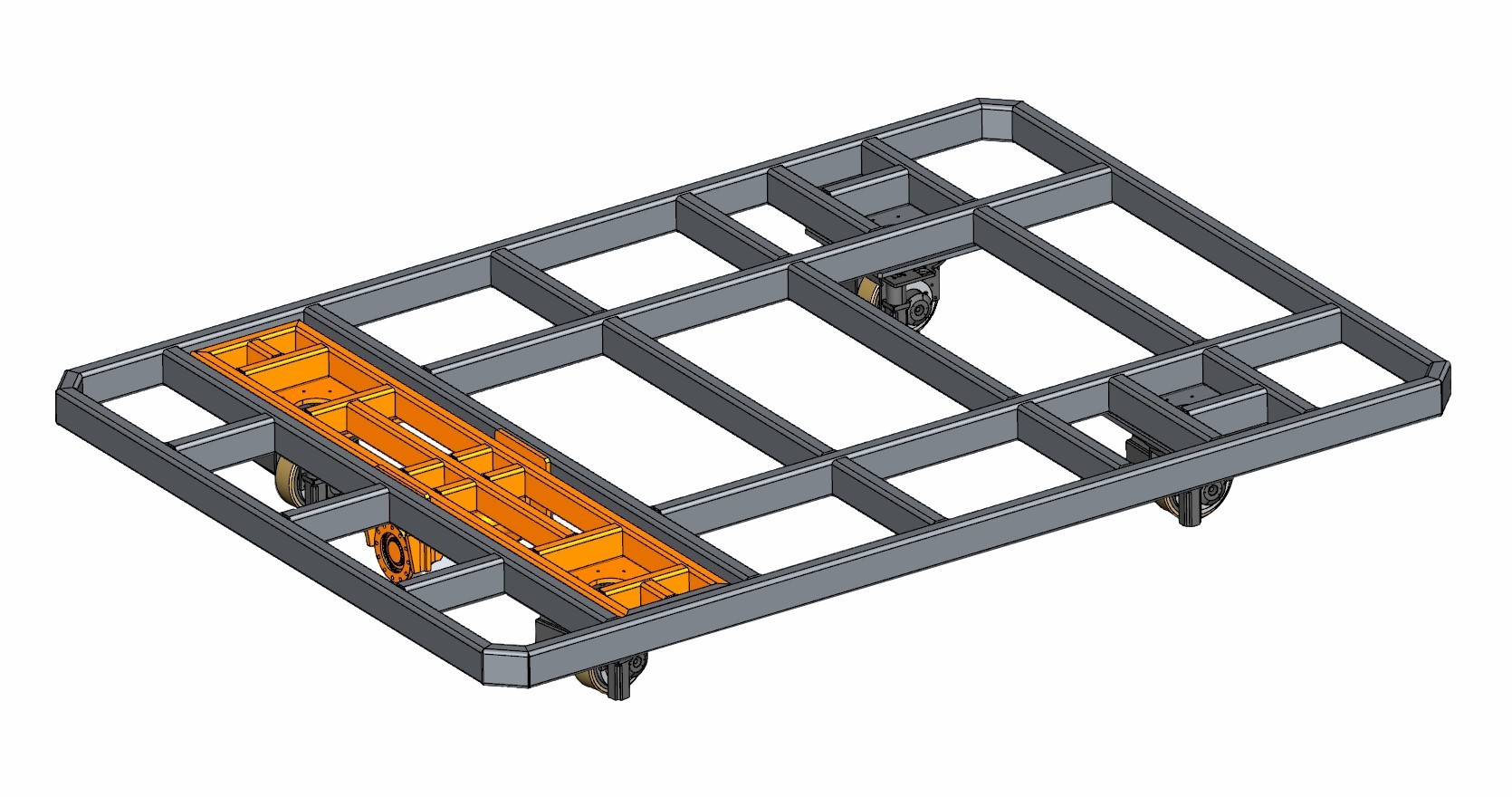

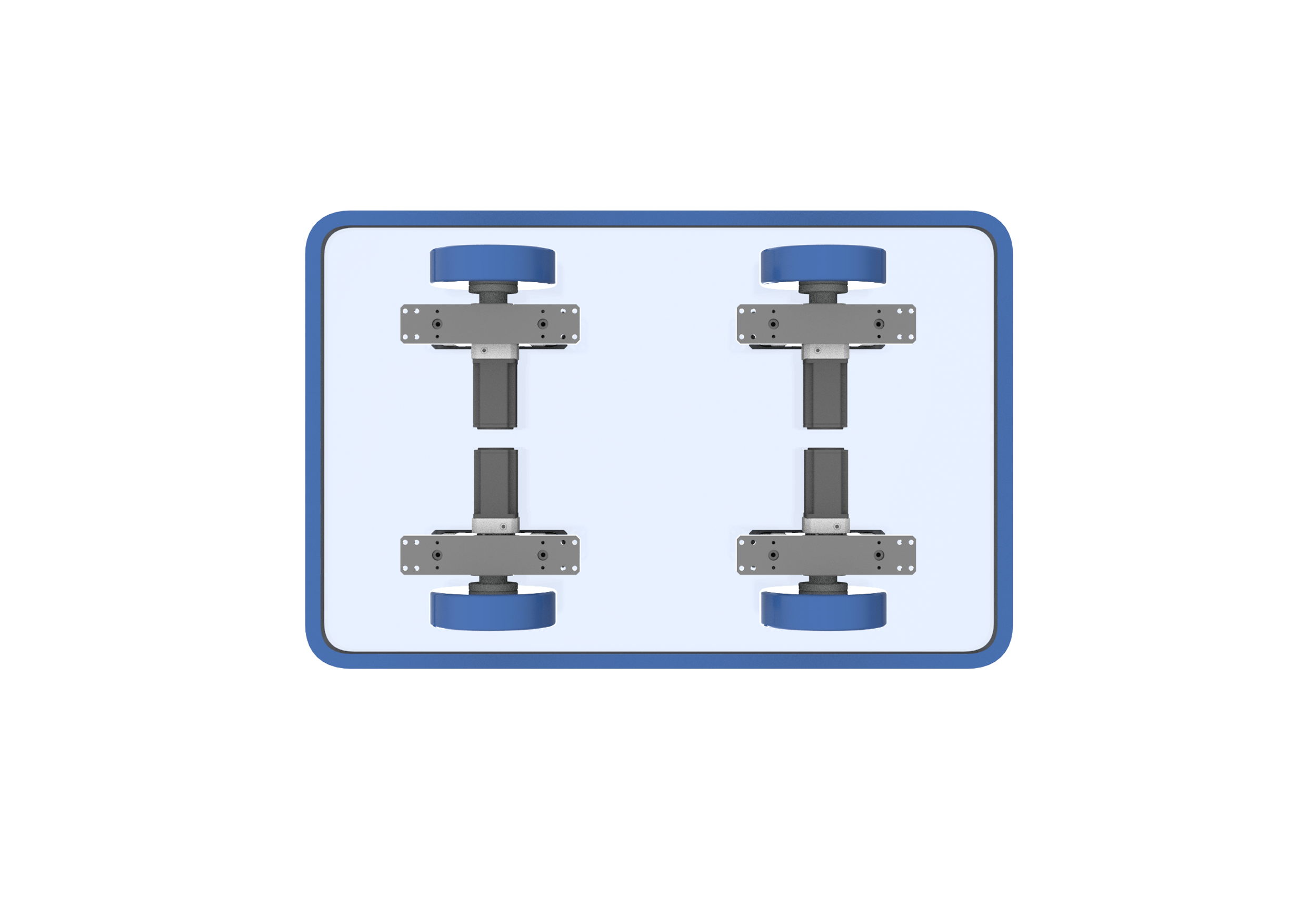

Dual-Steering-Wheel System: Typically employs a “dual-drive + 1 caster” or “dual-drive + 2 casters” layout. Two intelligent steering wheels (integrating drive, steering, and load-bearing functions) provide power and directional control, paired with one or more passive wheels for support and tracking. This structure is relatively simple.

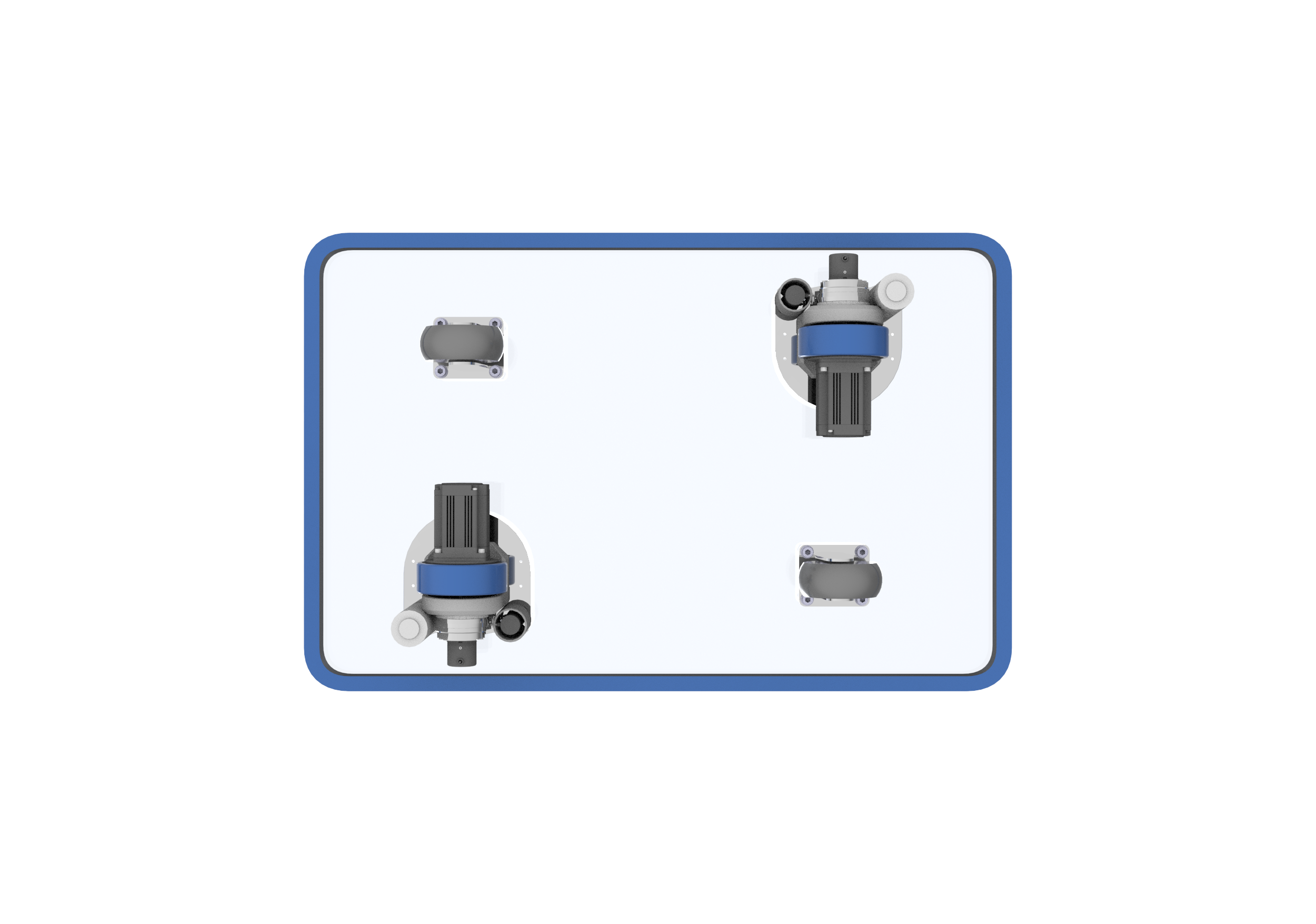

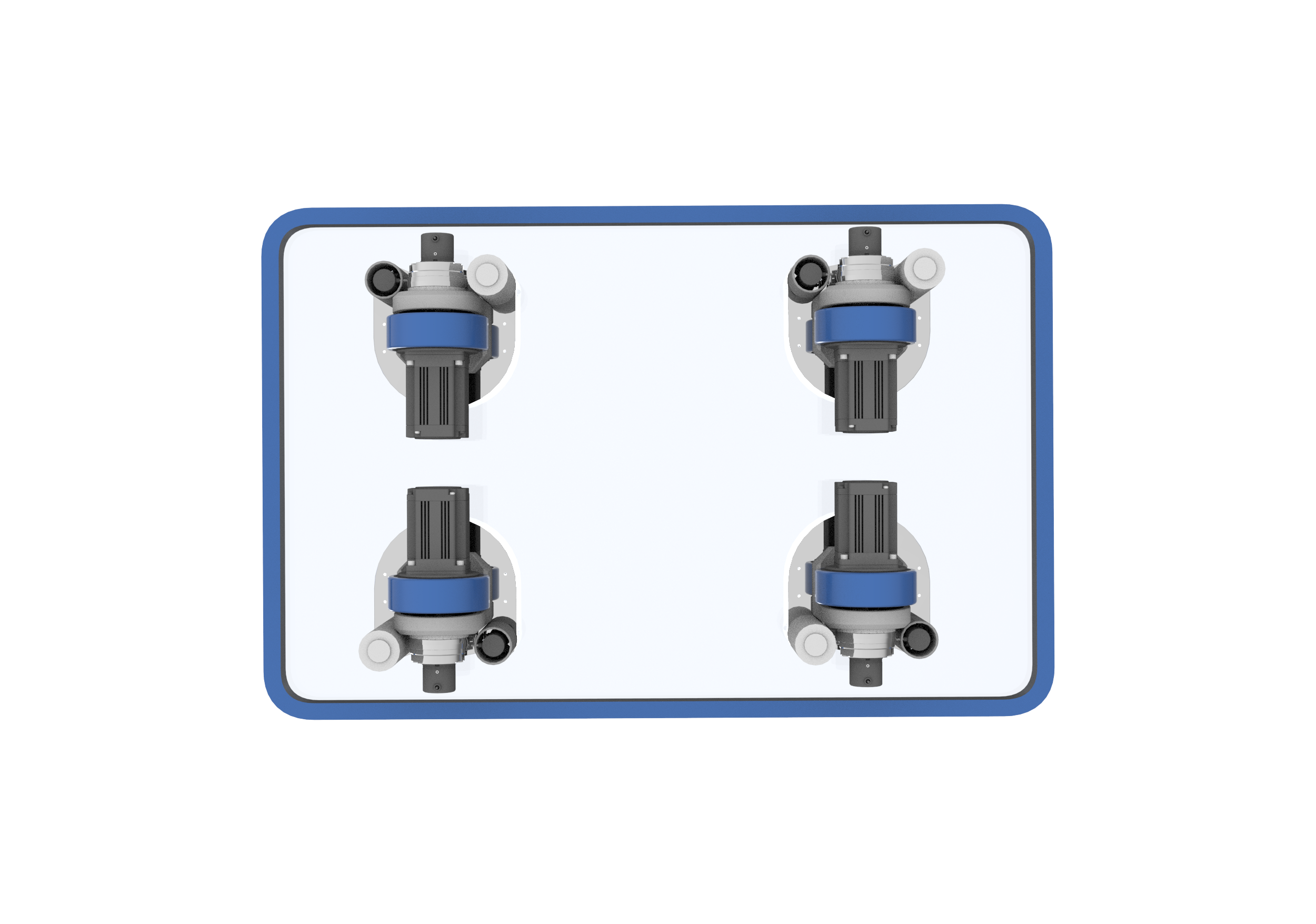

Quad-Wheel System: Employs four fully identical smart wheels symmetrically positioned at the vehicle's four corners. This “all-wheel-active” design eliminates traditional passive wheels entirely. Each wheel actively generates force and steers independently, resulting in an exponential increase in mechanical complexity.

2. Generational Leap in Mobility Capabilities

Dual-Steering-Wheel System: Achieves fundamental omnidirectional movement, including forward/reverse motion, turns with arbitrary radii, and zero-radius pivoting. Its mobility patterns satisfy most conventional material handling demands, offering flexibility far surpassing traditional forklifts and differential-drive AGVs.

Quad-Steering-Wheel System: Represents the pinnacle of current AGV mobility. Through precise vector synthesis control of all four wheels' speed and angle via a central controller, AGVs achieve truly omnidirectional movement: straight travel, lateral translation (crab steering), diagonal movement, and rotation around any point. This capability offers revolutionary advantages in extremely narrow, congested spaces.

3. Complex Hierarchy of Control Algorithms

Dual-wheel steering control algorithms are relatively mature. The core challenge of the quad-steering wheel system lies in multi-wheel coordinated control. The controller must compute motion commands for all four wheels in real time, ensuring they “pull together in the same direction” to avoid internal force losses caused by asynchrony (i.e., wheels “fighting” each other). This prevents increased power consumption, component wear, and even vehicle vibration. This places extremely high demands on the controller's computational power and algorithmic sophistication.

II. Advantageous Trade-offs: The Ultimate Balance of Performance, Cost, and Application Scenarios

Dual Steering Wheel Drive: The Cost-Effectiveness Champion, a Pragmatic Choice

Core Advantages:

Exceptional Cost-Effectiveness: Steering wheels rank among the most expensive components of AGVs. Eliminating two steering wheels directly reduces costs in hardware procurement, motor drives, and wiring harness layout, resulting in a highly competitive overall price.

Lower Maintenance Complexity: Fewer moving parts translate to reduced failure rates. Its relatively simple system facilitates easier maintenance and requires lower technical expertise from on-site personnel.

Meets Standard Requirements: For most scenarios—including warehouse logistics, production line material handling, and picking operations—the flexibility and load capacity (typically 1-3 tons) provided by dual steering wheels are fully adequate. This makes it a robust, reliable, and economical solution for automation upgrades.

Potential Limitations:

On extremely uneven surfaces, suspension of the driven wheels may cause slippage of the drive wheels.

Precise lateral translation is unattainable, requiring algorithmic compensation during path tracking.

Load capacity has an upper limit, making it unsuitable for heavy-duty applications.

Four-Wheel Steering Drive: Performance Flagship, Professional Powerhouse

Core Advantages:

Exceptional Load Capacity & Stability: Four steering wheels share the load and drive, effortlessly handling heavy-duty conditions from 3 tons to tens of tons. The stable support platform formed by all four wheels delivers unmatched anti-tip capability and stability during high-speed operation or when forks are raised high.

Ultimate Flexibility: True omnidirectional mobility enables precise positional adjustments in confined spaces unattainable by other AGVs. Ideal for millimeter-level positioning in aircraft assembly, precision instrument manufacturing, and ultra-narrow aisle access.

Superior Terrain Adaptation: Four-wheel drive delivers robust traction and grip, enabling seamless navigation over common workshop obstacles like gentle slopes, seams, and uneven surfaces while significantly reducing slip risks.

Potential Limitations:

High Initial Investment: Hardware and system development costs significantly exceed those of dual-steering-wheel systems.

Greater Maintenance Complexity and Cost: Requires specialized technical teams for maintenance and servicing.

Relatively Higher Energy Consumption: Powering four motors typically results in greater overall power consumption.

Wisdom Wheel Tech., we possess both mature dual-wheel and quad-wheel platform technologies, backed by extensive cross-industry application experience.

Our engineering team stands ready to serve as your trusted partner, immersing ourselves in your operational environment to deliver impartial, professional, and objective technical selection analysis alongside customized solutions—ensuring the success of your automation projects.

Contact our technical consultants today to chart the optimal course for your smart logistics journey.

Sales Manager:Jackson Lee +86-18011855485

Related news

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct