News Categories

Maximizing Efficiency with Quality Industrial Drive Wheels: The Ultimate Guide

Release time:

2025-09-09

Maximizing Efficiency with Quality Industrial Drive Wheels

Table of Contents

- 1. Introduction to Industrial Drive Wheels

- 2. The Importance of Quality Drive Wheels in Industrial Settings

- 3. Types of Industrial Drive Wheels

- 3.1 Rubber Drive Wheels

- 3.2 Metal Drive Wheels

- 3.3 Polyurethane Drive Wheels

- 3.4 Custom Drive Wheels

- 4. Key Factors to Consider When Choosing Drive Wheels

- 5. Best Practices for Installing Drive Wheels

- 6. Maintenance Tips for Longevity and Efficiency

- 7. Case Studies: Efficiency Gains from Quality Drive Wheels

- 8. FAQs

- 9. Conclusion

1. Introduction to Industrial Drive Wheels

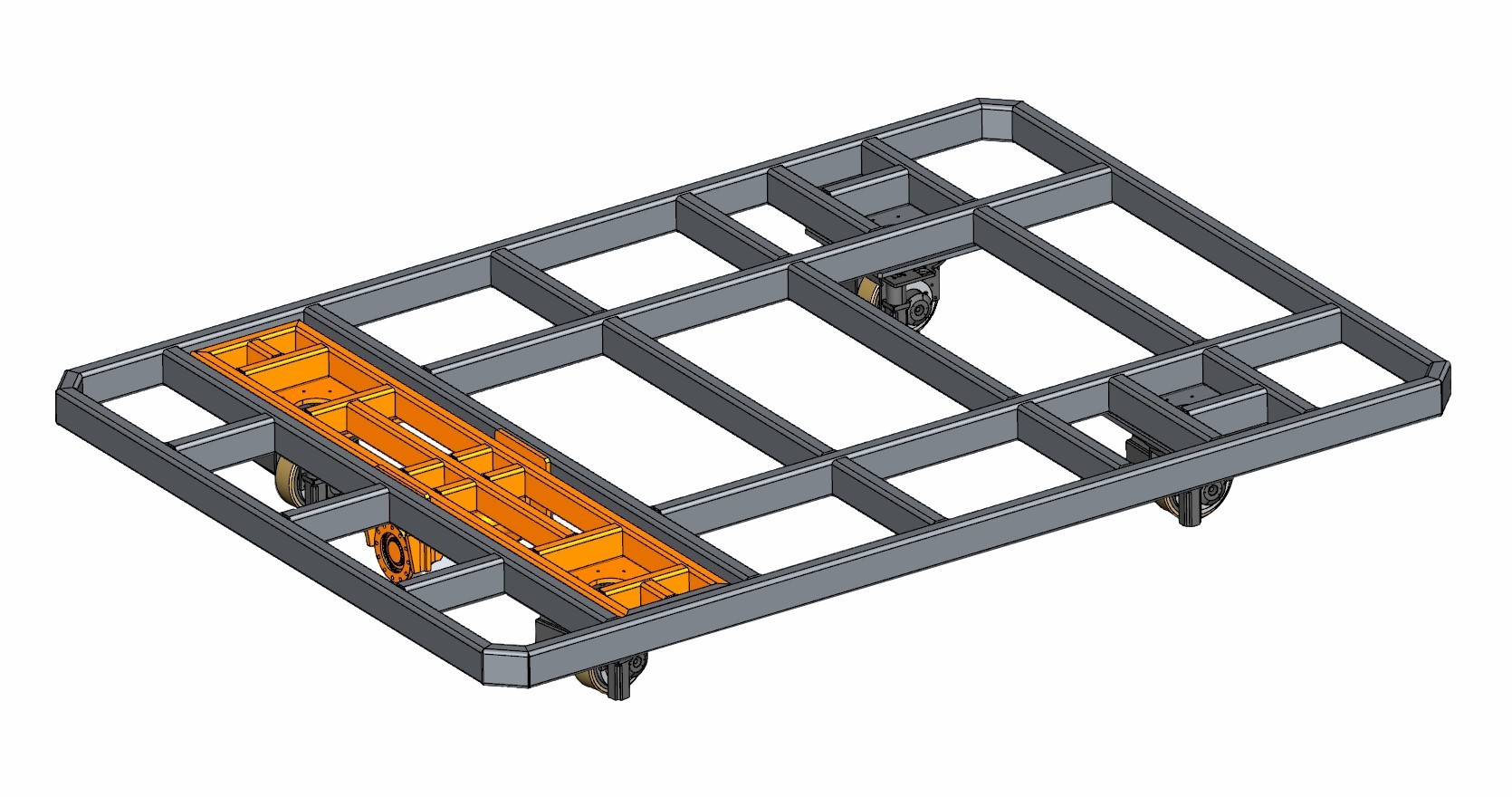

Industrial drive wheels serve as crucial components in various applications, ranging from logistics and manufacturing to construction and heavy equipment. Their primary function is to facilitate movement and ensure the operational efficiency of machinery. By investing in quality industrial drive wheels, businesses can significantly enhance their productivity and reduce operational costs.

2. The Importance of Quality Drive Wheels in Industrial Settings

Quality drive wheels are essential for several reasons:

- **Operational Efficiency**: High-quality drive wheels improve the overall efficiency of machinery, allowing for smoother and faster operations.

- **Durability**: Quality materials used in drive wheel manufacturing ensure a longer lifespan, reducing the need for frequent replacements and maintenance.

- **Safety**: Reliable drive wheels contribute to safer operations by minimizing the risk of equipment failure, which can lead to accidents and downtime.

By prioritizing the selection of quality drive wheels, businesses can create a solid foundation for enhanced productivity and safety in their operations.

3. Types of Industrial Drive Wheels

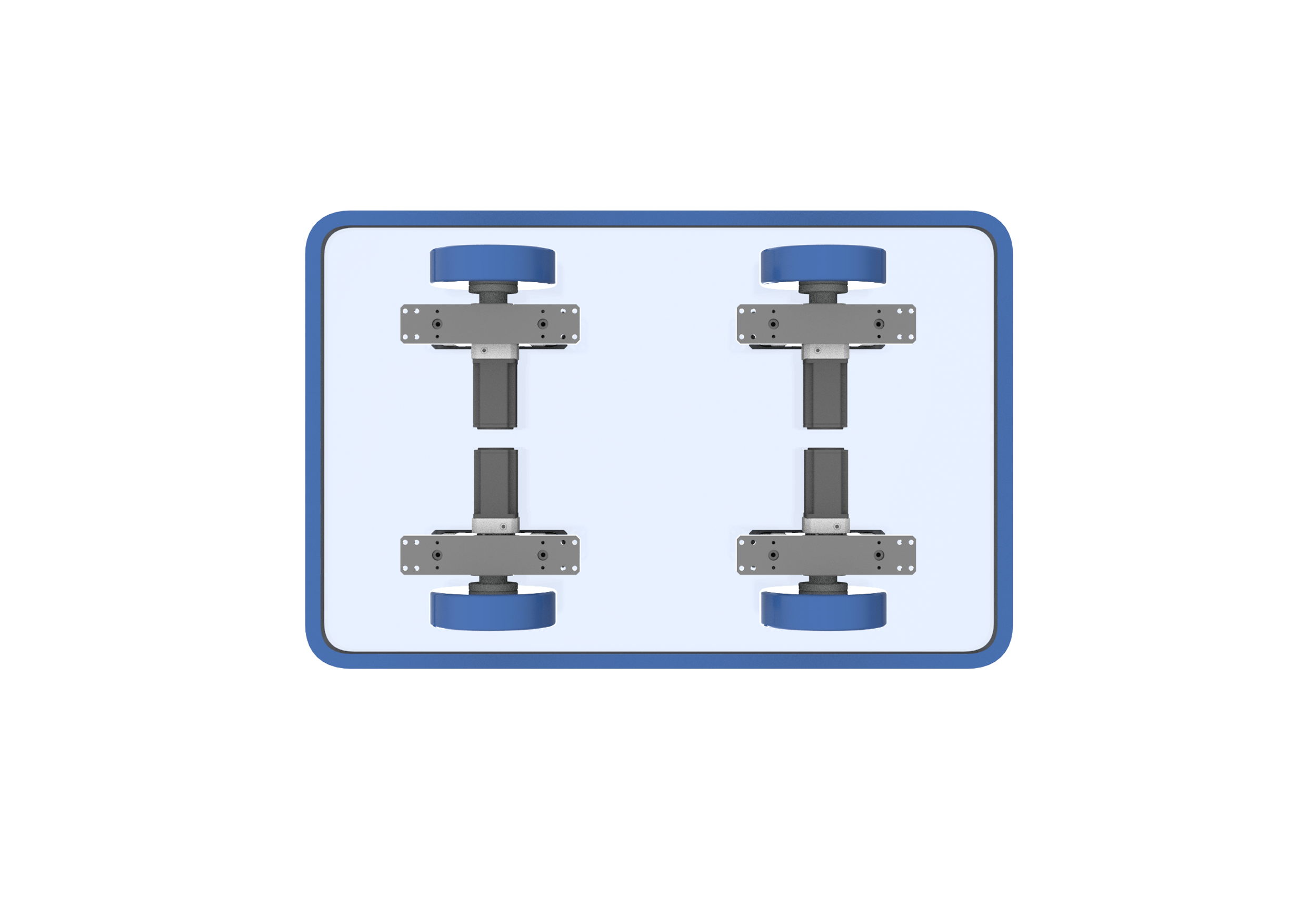

Different applications require specific types of drive wheels. Understanding the variations can help businesses choose the best option for their needs.

3.1 Rubber Drive Wheels

Rubber drive wheels are popular for their excellent grip and shock-absorbing properties. They are ideal for indoor applications and on surfaces that require a softer touch, such as warehouses and assembly lines. Rubber wheels minimize noise and vibrations, enhancing overall comfort during operation.

3.2 Metal Drive Wheels

Metal drive wheels are known for their strength and durability. They are commonly used in heavy-duty applications, such as construction and manufacturing. These wheels can withstand high loads and harsh environmental conditions, making them suitable for outdoor use.

3.3 Polyurethane Drive Wheels

Polyurethane drive wheels offer a balanced combination of durability and performance. They provide excellent resistance to abrasion, chemicals, and temperature fluctuations. These wheels are versatile and can be used in various settings, including hospitals, food processing plants, and warehouses.

3.4 Custom Drive Wheels

For specialized applications, custom drive wheels can be designed to meet specific requirements. Businesses can work with manufacturers to create wheels tailored to their operational needs, ensuring optimal performance and efficiency.

4. Key Factors to Consider When Choosing Drive Wheels

Selecting the right drive wheels requires consideration of several critical factors.

4.1 Load Capacity

The load capacity of drive wheels is crucial for ensuring they can handle the weight of the machinery and materials. It is essential to assess the maximum load requirements and choose wheels that can support them safely.

4.2 Environmental Conditions

Understanding the environment in which the drive wheels will operate is vital. Factors such as temperature, humidity, and exposure to chemicals can affect the performance and durability of the wheels. Selecting materials that withstand these conditions will extend the lifespan of the drive wheels.

4.3 Speed and Performance

Different applications require varying speeds of operation. It is essential to consider the desired speed and performance when choosing drive wheels. Wheels designed for high-speed applications should be balanced and constructed from materials that can endure rapid movement without wear.

5. Best Practices for Installing Drive Wheels

Proper installation of drive wheels is essential for optimal performance. Here are some best practices:

- **Alignment**: Ensure that the wheels are correctly aligned with the drive system to prevent unnecessary wear and tear.

- **Torque Specifications**: Follow the manufacturer’s torque specifications for fasteners to secure the wheels properly.

- **Maintenance Checks**: Conduct regular maintenance checks after installation to identify any issues early and maintain performance.

6. Maintenance Tips for Longevity and Efficiency

Regular maintenance is key to maximizing the efficiency and lifespan of industrial drive wheels. Here are some essential tips:

- **Regular Inspections**: Check for signs of wear, damage, or misalignment regularly.

- **Cleaning**: Keep the wheels clean from debris and contaminants that can hinder performance.

- **Lubrication**: Apply appropriate lubricants as recommended by the manufacturer to reduce friction and wear.

- **Replacement Schedule**: Establish a replacement schedule based on usage and wear patterns to avoid unexpected failures.

7. Case Studies: Efficiency Gains from Quality Drive Wheels

Several industries have witnessed significant efficiency gains by investing in quality drive wheels.

- **Manufacturing Plant**: A manufacturing facility replaced its outdated drive wheels with high-performance polyurethane options. This led to a 20% increase in production speed and a 15% reduction in maintenance costs over a year.

- **Logistics Warehouse**: A logistics company upgraded to rubber drive wheels in their forklifts, resulting in decreased noise levels and improved worker satisfaction. This change also enhanced the overall safety of operations, leading to fewer incidents.

These case studies illustrate the tangible benefits of prioritizing quality in drive wheel selection and maintenance.

8. FAQs

What are the primary materials used in industrial drive wheels?

The most common materials include rubber, metal, and polyurethane. Each material offers unique benefits tailored to specific applications.

How do I determine the right load capacity for my drive wheels?

Evaluate the maximum weight your machinery and materials will exert on the wheels, and select wheels rated for at least that load plus a safety margin.

Can I use rubber drive wheels outdoors?

While rubber wheels can be used outdoors, they are more suited for indoor applications. For outdoor use, consider metal or polyurethane wheels.

What maintenance is required for drive wheels?

Regular inspections, cleaning, lubrication, and timely replacements are essential for maintaining the performance and longevity of drive wheels.

How do custom drive wheels differ from standard options?

Custom drive wheels are designed specifically to meet unique operational requirements, ensuring optimal performance for specialized applications.

9. Conclusion

Maximizing efficiency in industrial operations is crucial for competitiveness and sustainability. Quality drive wheels play a pivotal role in achieving this goal. By understanding the different types, key selection factors, and maintenance practices, businesses can leverage the benefits of high-quality drive wheels to enhance productivity and safety. Investing in the right drive wheels today leads to a more efficient and profitable tomorrow.

Related news

2025-09-09

Maximizing Efficiency with Quality Industrial Drive Wheels: The Ultimate Guide

Maximizing Efficiency with Quality Industrial Drive Wheels

Table of Contents

1. Introduction to Industrial Drive Wheels

2. The Importance of Quality Drive Wheels in Industrial Settings

3. Types of Industrial Drive Wheels

3.1 Rubber Drive Wheels

3.2 Metal Drive Wheels

3.3 Polyurethane Drive Wheels

3.4 Custom Drive Wheels

4. Key Factors to Consider When

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License