News Categories

Maximizing Performance: The Critical Role of New AGV Wheels in Driving Efficiency

Release time:

2025-08-02

Maximizing Performance: The Critical Role of New AGV Wheels in Driving Efficiency

Table of Contents

- Introduction to AGV Wheels and Their Importance

- Understanding AGV Wheels: An Overview

- Benefits of Upgrading to New AGV Wheels

- Types of AGV Wheels to Consider

- Factors Influencing Your Choice of AGV Wheels

- Impact on Efficiency and Performance

- Common Misconceptions About AGV Wheels

- Conclusion: Investing in New AGV Wheels

- Frequently Asked Questions

Introduction to AGV Wheels and Their Importance

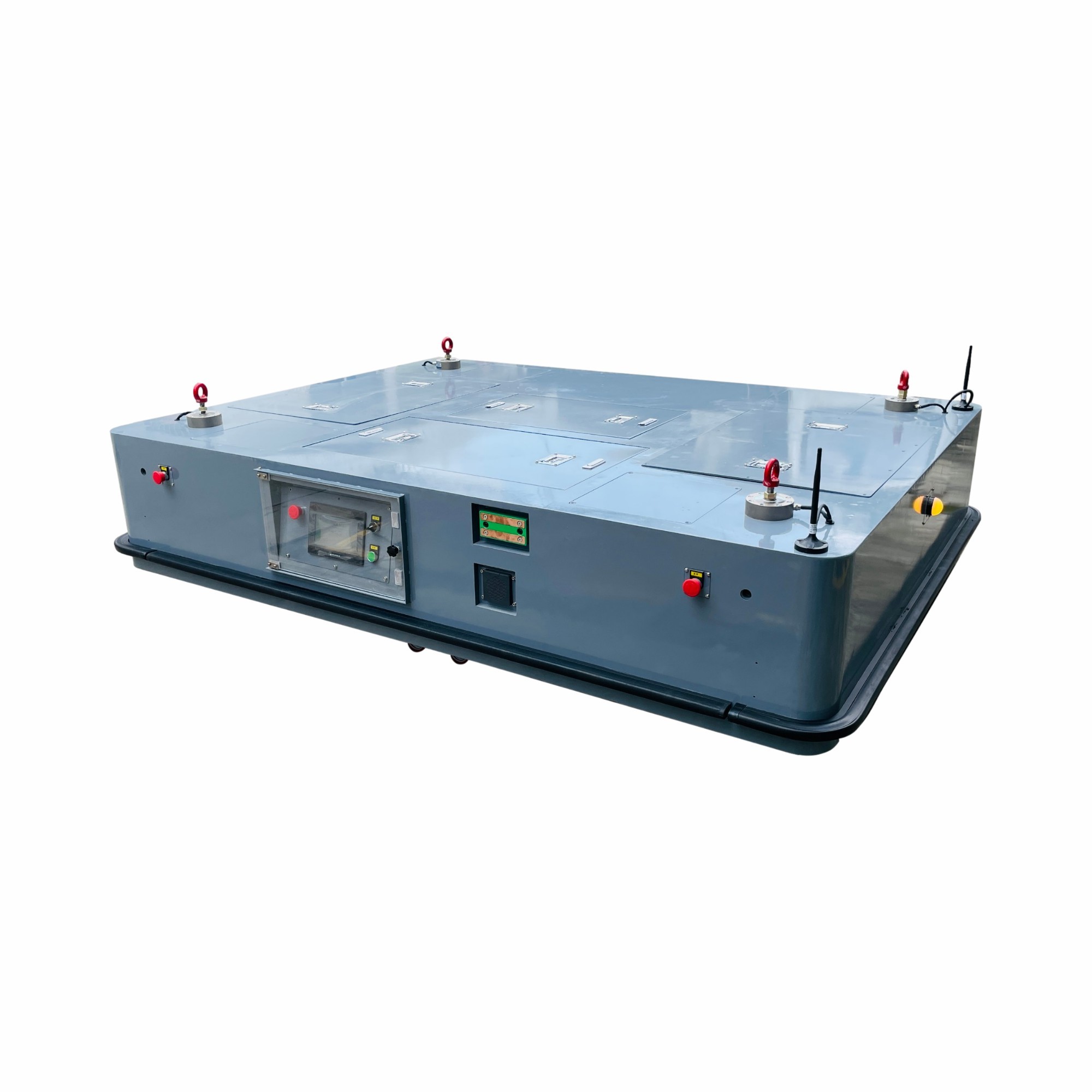

In the world of modern industrial automation, **Automated Guided Vehicles** (AGVs) play a pivotal role in streamlining operations and enhancing productivity. A crucial component of these systems is the **AGV wheels**, which are designed to facilitate smooth movement and maneuverability. As industries evolve, so do the demands placed on AGVs, making the performance and reliability of their wheels more critical than ever. Upgrading to **new AGV wheels** not only boosts performance but also extends the life of your equipment and optimizes operational efficiency.

Understanding AGV Wheels: An Overview

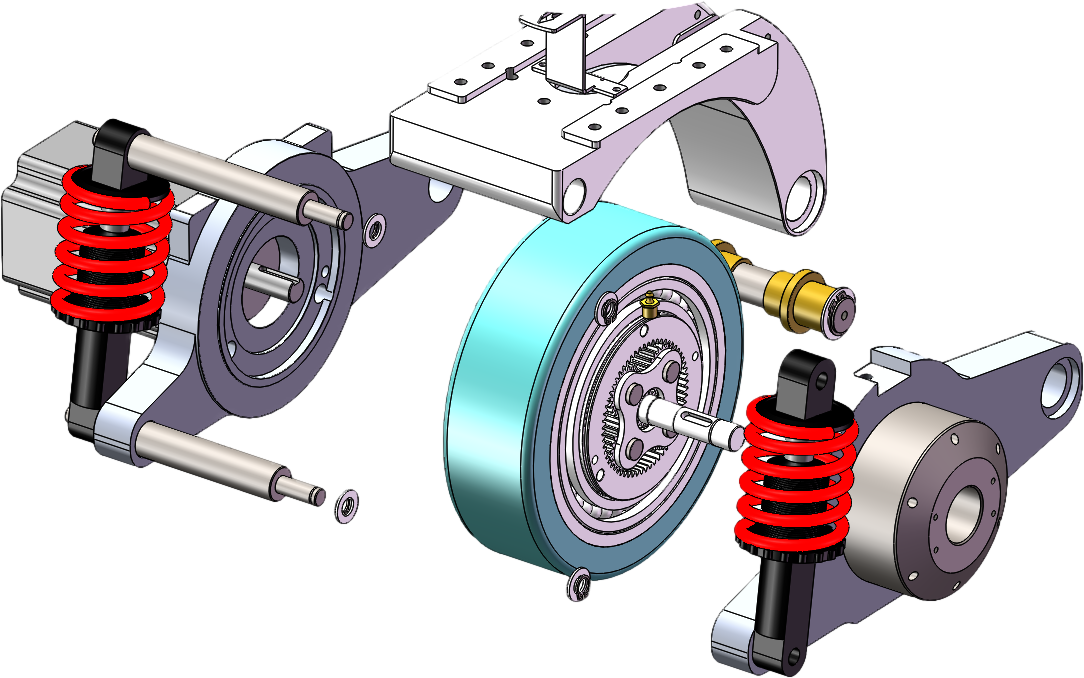

AGV wheels come in various types, each engineered for specific applications. They are typically categorized based on their construction materials, design, and functionality. Most commonly, AGV wheels are made from polyurethane, rubber, or metal, and each material imparts unique characteristics in terms of grip, durability, and performance.

**AGV wheels** are not just about movement; they also influence several essential factors, including load capacity, friction, and wear resistance. Therefore, understanding your operational needs is vital when selecting the right wheels.

Benefits of Upgrading to New AGV Wheels

The decision to invest in new AGV wheels can have far-reaching benefits for your operations. Here are some compelling reasons to consider upgrading:

Enhanced Performance and Efficiency

New AGV wheels are engineered with the latest technology and materials that significantly enhance their performance. They provide better traction, smooth movement, and reduced noise levels, which are essential in maintaining an efficient workflow.

Reduced Maintenance Costs

A key advantage of new wheels is their ability to reduce wear and tear on your AGV system. Modern wheels are designed for longevity, which means less frequent replacements and lower maintenance costs. This not only saves money but also minimizes operational downtime.

Improved Safety Standards

Safety is a top priority in any industrial setting. Upgrading to new AGV wheels can significantly reduce accidents related to wheel failure or poor grip, thus enhancing overall workplace safety.

Compatibility with Advanced Technology

New AGV wheels are often designed to be compatible with advanced automation technologies, such as smart navigation systems and AI-driven logistics solutions. This compatibility can lead to more efficient and streamlined operations.

Types of AGV Wheels to Consider

Choosing the right type of AGV wheel depends on several factors, including the nature of the surface, load capacity, and operational requirements. Here are some common options:

Polyurethane Wheels

Polyurethane wheels are popular due to their durability and excellent grip. They are ideal for indoor applications where smooth surfaces prevail, offering a balance between performance and cost-effectiveness.

Rubber Wheels

Rubber wheels are known for their shock-absorbing properties, making them suitable for environments with uneven surfaces. They provide excellent traction and are often used in outdoor applications.

Metal Wheels

For heavy-duty operations, metal wheels are often the best choice due to their strength and durability. They are typically used in environments where high loads and rugged conditions are prevalent.

Factors Influencing Your Choice of AGV Wheels

Selecting the right AGV wheels involves considering several critical factors:

Load Capacity

The wheel's load capacity must match the weight of the loads being transported. Overloading can lead to premature wear and potential system failure.

Surface Conditions

Consider the type of surfaces the AGVs will operate on. Smooth, flat surfaces may require different wheels compared to rough terrains.

Speed Requirements

Wheels designed for higher speeds may require different materials and designs to ensure safety and performance.

Environmental Factors

Consider environmental factors such as temperature, humidity, and exposure to chemicals, which can affect wheel performance.

Impact on Efficiency and Performance

The impact of new AGV wheels on operational efficiency cannot be overstated. Enhanced wheels contribute to:

Increased Throughput

With improved wheel performance, AGVs can operate more efficiently, leading to higher throughput. This means more goods can be moved in less time, positively affecting overall productivity.

Reduction in Downtime

New wheels that require less frequent replacements and maintenance significantly reduce downtime. This uninterrupted operation is crucial for maintaining a competitive edge in the market.

Better Maneuverability

New wheel designs offer superior maneuverability, allowing AGVs to navigate tight spaces and complex pathways with ease. This flexibility can improve the layout of your operational environment.

Common Misconceptions About AGV Wheels

Despite their importance, several misconceptions about AGV wheels may lead to poor decision-making:

New Wheels Are Always Expensive

While some high-end wheels may come with a higher price tag, the cost savings in maintenance and improved performance often justify the investment.

All Wheels Are the Same

Not all AGV wheels are created equal. Understanding the specific needs of your operation is vital for selecting the right wheels.

Upgrading Is Unnecessary

Many businesses underestimate the impact of new AGV wheels. Continuous advancements in technology mean that newer wheels can offer significant performance enhancements over older models.

Conclusion: Investing in New AGV Wheels

In conclusion, the selection of new AGV wheels is a critical investment for any operation relying on automated guided vehicles. By focusing on performance, efficiency, and safety, businesses can maximize their operational capabilities. Upgrading to the latest wheel technology not only improves productivity but also reduces maintenance costs and enhances workplace safety.

As industries continue to evolve, staying ahead of the curve with the right equipment is essential for sustained success. The right **AGV wheels** will not only enhance your systems but will also provide a competitive advantage in a rapidly changing marketplace.

Frequently Asked Questions

1. How often should AGV wheels be replaced?

The lifespan of AGV wheels depends on usage, but generally, they should be inspected regularly and replaced every 1-2 years for optimal performance.

2. What factors should I consider when choosing AGV wheels?

Consider factors such as load capacity, surface conditions, speed requirements, and environmental factors when selecting AGV wheels.

3. Can I retrofit my existing AGVs with new wheels?

Yes, most AGVs can be retrofitted with new wheels, but it’s essential to ensure compatibility with your existing systems.

4. How do I know if my AGV wheels need replacing?

Signs of wear, such as cracks, uneven tread, or reduced traction, indicate that it’s time to replace your AGV wheels.

5. Are there specific brands of AGV wheels that are recommended?

Choosing a reputable brand that specializes in AGV components is crucial. Research and reviews can help identify reliable manufacturers.

Related news

2025-08-02

Maximizing Performance: The Critical Role of New AGV Wheels in Driving Efficiency

Maximizing Performance: The Critical Role of New AGV Wheels in Driving Efficiency

Table of Contents

Introduction to AGV Wheels and Their Importance

Understanding AGV Wheels: An Overview

Benefits of Upgrading to New AGV Wheels

Types of AGV Wheels to Consider

Factors Influencing Your Choice of AGV Wheels

Impact on Efficiency and Performance

Common Misconceptions About AG

2025-07-28

Exploring the Benefits of Durable AGV Platforms in Logistics and Warehousing

In the rapidly evolving world of logistics and warehousing, the adoption of durable AGV platforms has become a crucial factor in enhancing efficiency and productivity. These automated systems have revolutionized the way goods are transported within facilities, offering a wide range of benefits for businesses in the transportation and logistics sectors.

One of the primary advantages of durable AGV

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License