Differential Drive

Release time:

2025-07-25

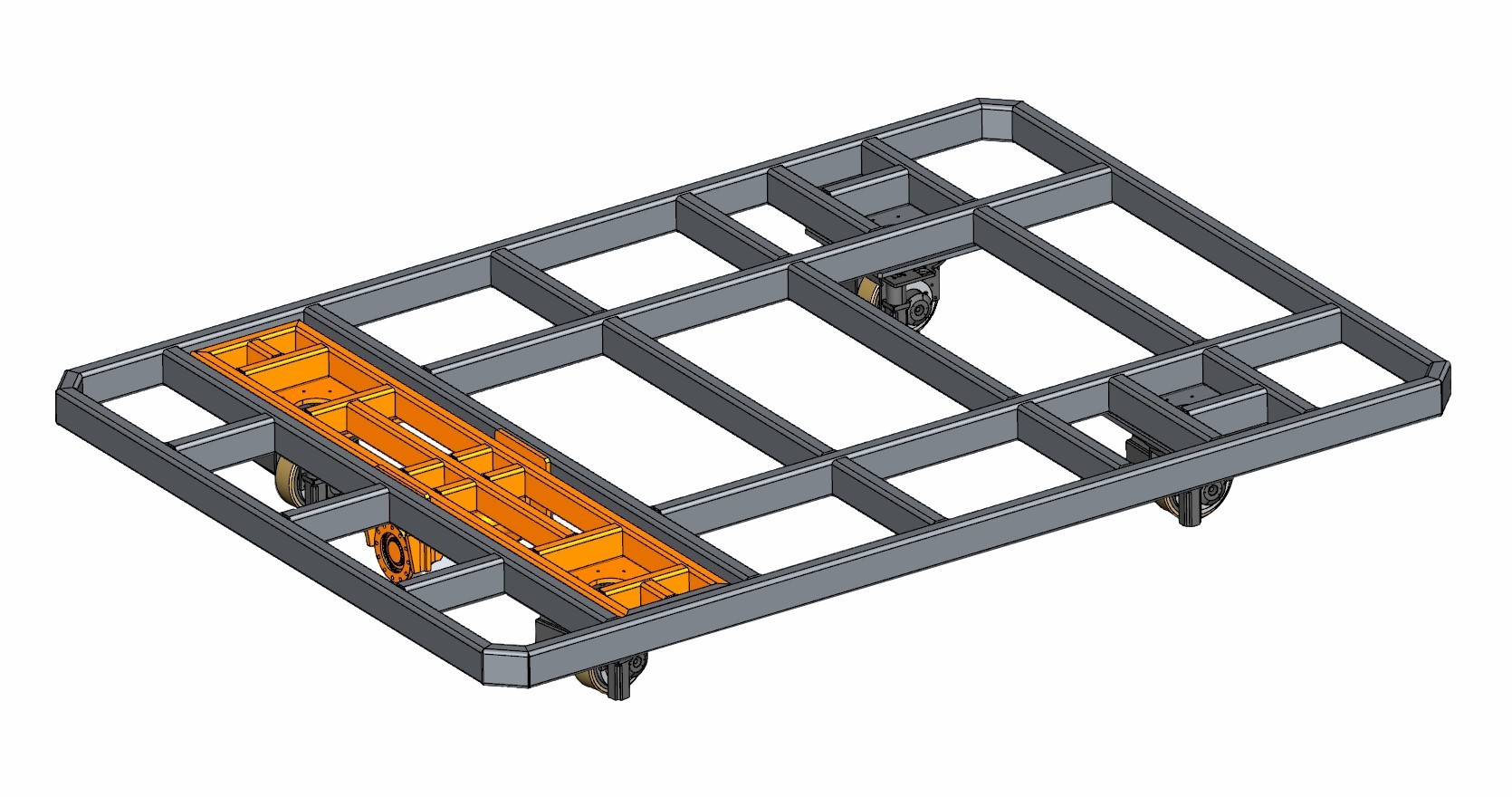

The AGV drive wheel is the core executive component of the AGV system, and its performance directly determines the AGV's mobility, load-bearing efficiency, operational stability, and overall reliability.

The drive wheel not only bears the weight of the vehicle and cargo, but also transmits driving force from the motor to the ground and is responsible for the vehicle's steering.

The design of AGV drive wheels is intended to withstand extremely high loads in limited spaces (such as small diameters and widths), capable of supporting the vehicle's own weight and a large amount of transported cargo.

For example, Feigeli AGV drive wheels feature a dual-component design combining a polyamide hub and a PAS-PU TCS rim. The rigid hub ensures high load capacity, enabling high loads even with smaller wheel diameters. In heavy-duty applications, the AGV steering wheel series can support loads of up to 10 tons per wheel. Additionally, dual-wheel AGV casters achieve load capacities exceeding 15,000 pounds through more even weight distribution, significantly enhancing stability.

To ensure reliable drive transmission, AGV drive wheels must have excellent traction on various surfaces. This is achieved through specially developed wheel rim surface materials, which offer extremely high wear resistance and outstanding traction. Advanced tread patterns, such as ribbed, lugged, and anti-slip stud designs, optimize traction based on the application environment, reduce slippage, and ensure the safety of vehicles, cargo, and personnel.

The continuous advancements in high load-bearing capacity and exceptional traction of AGV drive wheels respond to the growing demand from the industrial sector for automated heavy-duty material handling. As the application scope of AGVs expands, businesses require them to handle ultra-heavy-duty transportation tasks of 30 tons or even over 500 tons (through multi-vehicle coordination) in industries such as automotive, aerospace, and heavy machinery manufacturing. This expanded capability enables AGVs to transcend lightweight applications, positioning them as a powerful alternative to traditional forklifts and conveying systems, thereby driving the widespread adoption of automation across broader industrial scenarios. This trend indicates that the role of drive wheels in AGV systems is evolving from mere mobility components to critical enabling technologies for heavy-duty automation solutions.

Outstanding durability and wear resistance

The durability of AGV drive wheels is key to their long-term performance and reliability. They are typically made from durable materials such as rubber, polyurethane (PU), or steel, enabling them to withstand a wide range of harsh working conditions. In particular, polyurethane wheels are widely used in AGVs due to their exceptional wear resistance, cut resistance, and hydrolysis resistance, ensuring a longer service life and lower wear rates.

The robust structure of drive wheels enables them to withstand heavy loads, frequent impacts, and adverse environmental factors, reducing the need for frequent replacements and maintenance. For example, specially developed wheel surfaces exhibit extremely high wear resistance, maintaining performance even during sharp turns and stationary turns.

The exceptional durability and wear resistance of the drive wheels directly translate into low maintenance requirements and a long service life for AGVs, significantly reducing long-term operational costs for businesses. In industrial environments, AGVs require 24/7 continuous operation and often face heavy loads, impacts, and harsh conditions. If drive wheels wear out too quickly or are prone to damage, this leads to frequent replacements and downtime.

By using high-quality, wear-resistant materials and designing robust hub and rim structures, the service life of the drive wheels is extended, and failure rates are reduced. This reliability minimizes downtime caused by wheel failures, ensuring the high availability of the AGV system and the continuity of the production line.

Precise steering and flexible maneuverability

AGV drive wheels are key components for vehicle steering. AGV drive systems come in various types to accommodate different steering requirements:

Single-wheel drive: The most basic drive configuration, where a single motor drives one active wheel, with the remaining wheels being passive. This design is simple and cost-effective, suitable for scenarios with relatively fixed paths and low requirements for speed and steering flexibility.

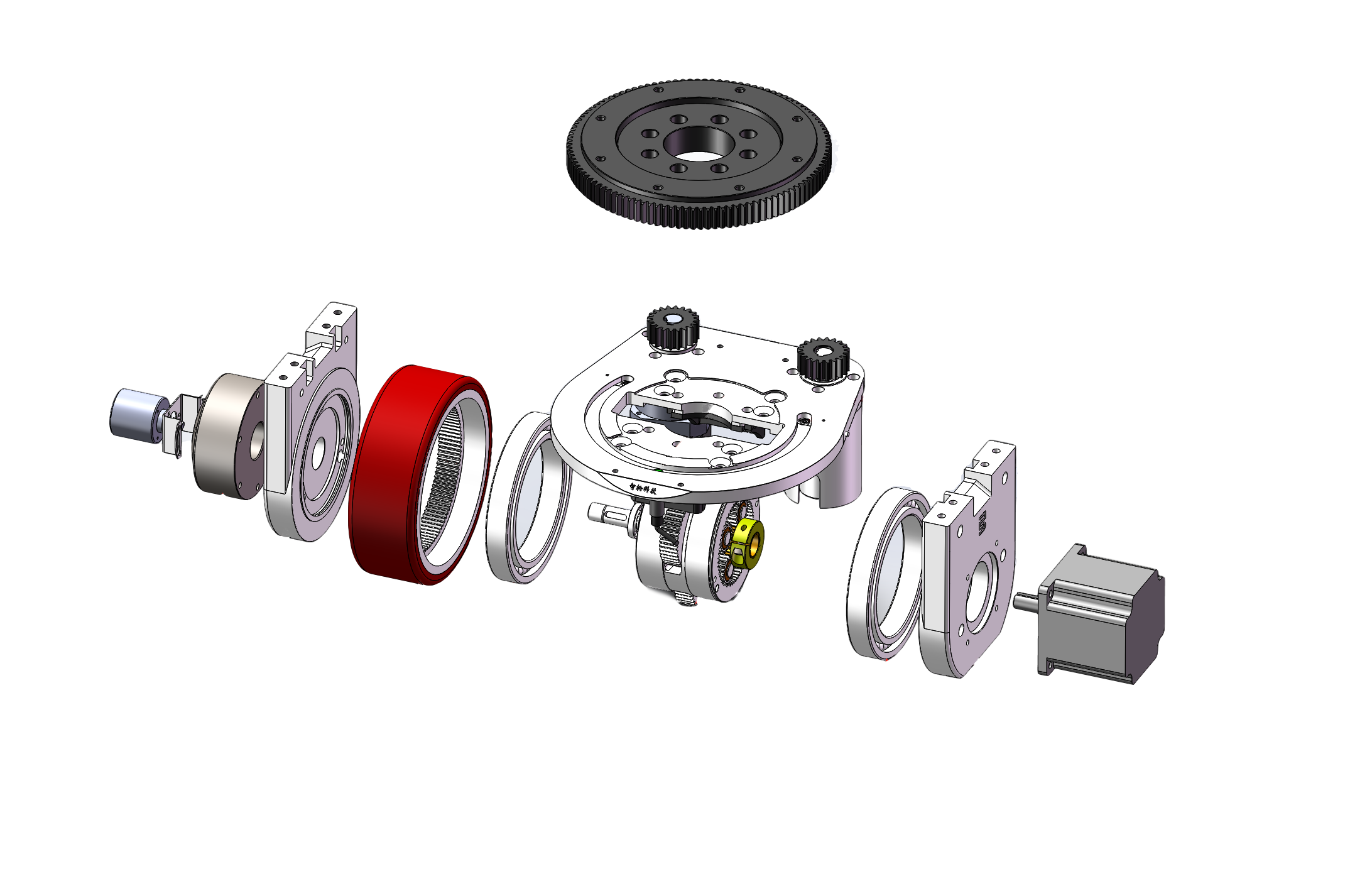

Differential drive: Achieves movement and steering through the speed difference between two independent drive wheels. This system is widely used in the logistics and warehousing industry, particularly in warehouses with complex shelf layouts and varying aisle widths, enabling flexible maneuvering and efficient material handling. Heavy-duty differential AGV motor wheels can support loads of up to 5,000 kg.

Omnidirectional drive: Utilizes specially designed wheels, such as Mecanum wheels, enabling the AGV to move in any direction, including forward, backward, lateral translation, and rotation. This unique movement capability allows it to navigate freely in extremely complex and narrow spaces, such as electronics manufacturing workshops and automated立体仓库. Mecanum wheels achieve omnidirectional movement by tilting rollers at a 45-degree angle and independently driving each wheel through combinations of speed and direction.

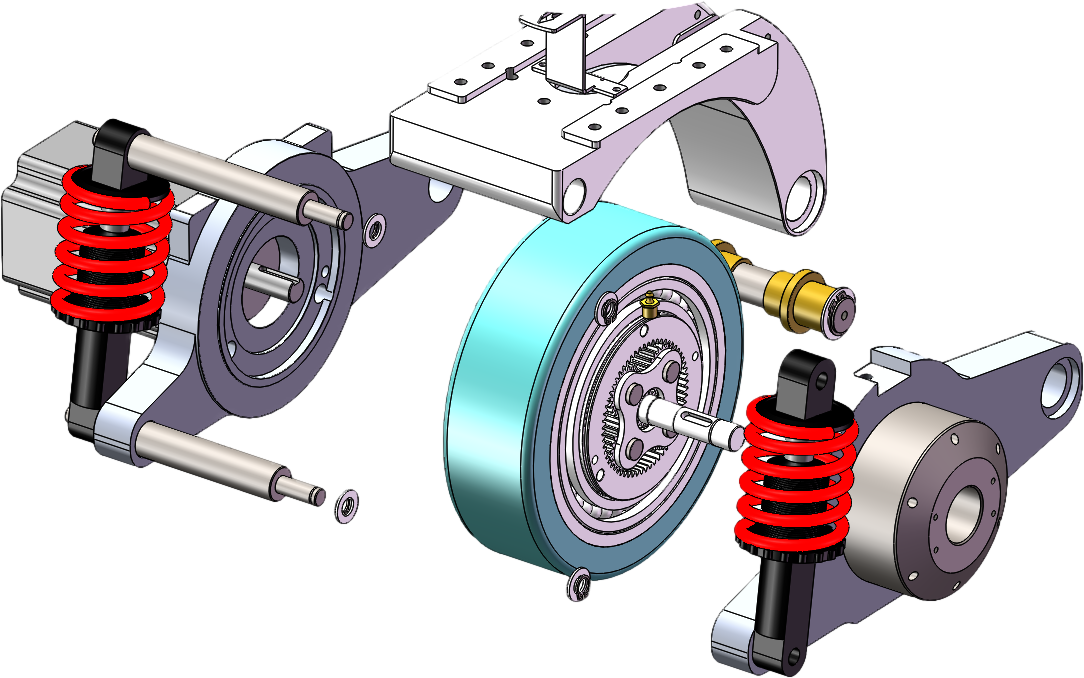

High-precision steering wheels, in conjunction with spiral planetary reducers and servo drives/motors, ensure precise operation and positioning. The compact vertical steering wheel design features a small turning radius, making it ideal for forklifts and stackers operating in narrow spaces. Some drive wheels are also equipped with ball screw mechanisms to further enhance movement precision, suitable for high-tech industries requiring precise handling of sensitive materials.

AGV drive systems have evolved from simple single-wheel drive to flexible differential drive, and ultimately to omnidirectional drive, reflecting the continuous advancement of AGV technology in addressing complex operational environments. As industrial environments become increasingly complex, higher demands are placed on AGV mobility and steering precision, such as narrow aisles, multi-point stops, and precise docking.

This evolution enables AGVs to transition from simple material handling along fixed paths to performing complex operations with high precision and multi-angle maneuvering in dynamic, narrow, or congested spaces. However, while omnidirectional drive offers flexibility, it also comes with higher control complexity, costs, and wear rates. This underscores the need to balance the selection of the most appropriate drive system based on specific application requirements rather than blindly pursuing the most advanced technology.

Related news

2025-12-08

The Science Behind New AGV Wheels and Their Impact on Drive Systems

2025-12-03

Exploring Durable AGV Platforms for Enhanced Logistics Efficiency

2025-11-28

The Top Applications for Quality Industrial Drive Wheels in the Automotive Industry

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct