News Categories

Exploring the Benefits of Durable AGV Platforms in Logistics and Warehousing

Release time:

2025-07-28

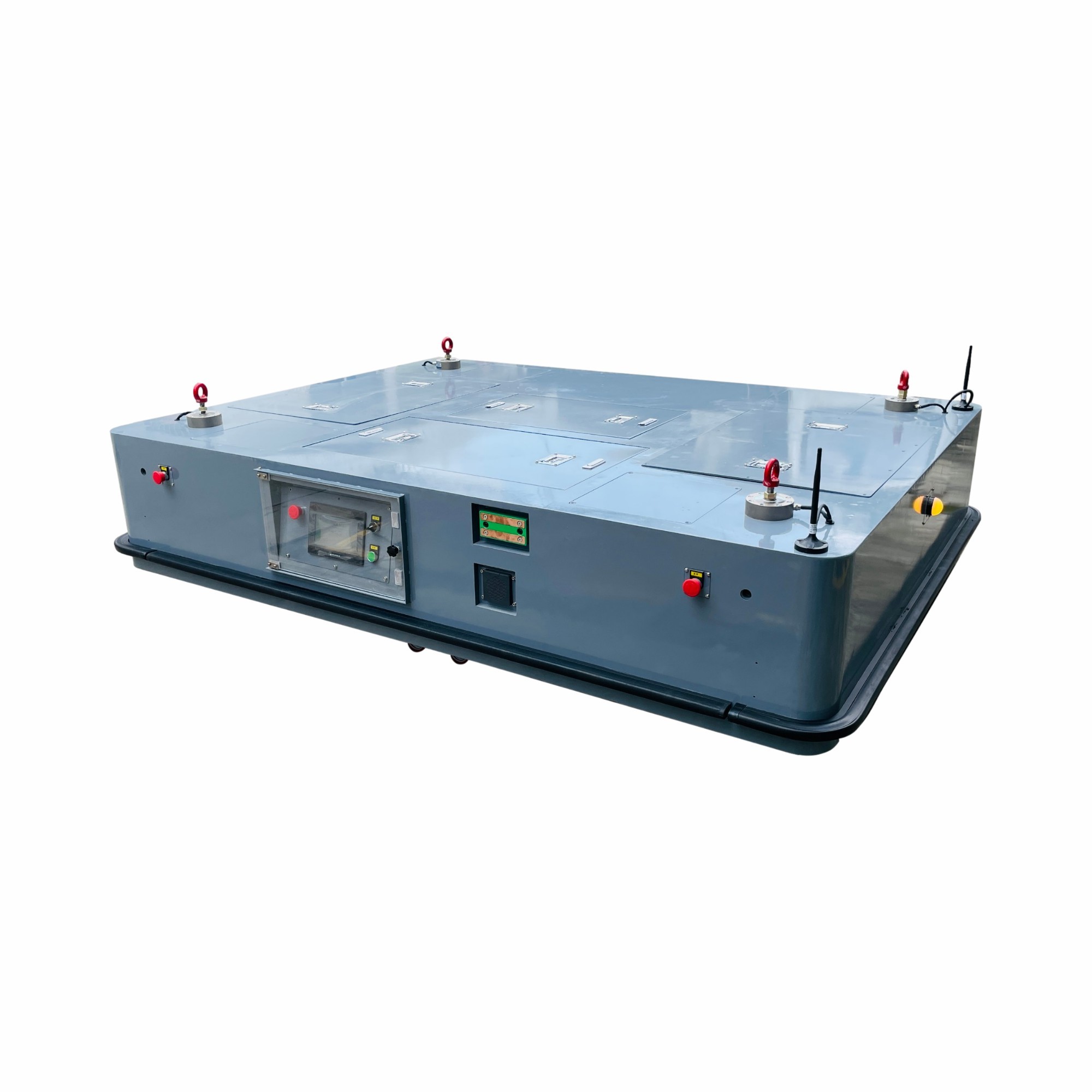

In the rapidly evolving world of logistics and warehousing, the adoption of durable AGV platforms has become a crucial factor in enhancing efficiency and productivity. These automated systems have revolutionized the way goods are transported within facilities, offering a wide range of benefits for businesses in the transportation and logistics sectors.

One of the primary advantages of durable AGV platforms is their ability to operate continuously, maximizing throughput while minimizing the need for human intervention. This is particularly beneficial in high-demand environments where the speed of operations is essential. Durable AGV platforms are designed to withstand harsh working conditions, ensuring that they can be relied upon for long periods without significant maintenance or downtime. This durability translates to a lower total cost of ownership, as businesses can avoid frequent repairs or replacements.

In addition to their robust construction, durable AGV platforms are equipped with advanced navigation technologies. These systems utilize a combination of sensors, cameras, and software to effectively navigate complex warehouse layouts. This not only enhances safety by reducing the risk of collisions but also improves the overall efficiency of material handling processes. Businesses can streamline their operations by integrating these platforms into their existing workflows, optimizing the movement of goods from storage to shipping areas.

Another important consideration is the flexibility offered by AGV platforms. They can be programmed to handle various loads and tasks, making them suitable for diverse applications within the logistics sector. From pallet transport to order picking, durable AGV platforms can adapt to different operational needs, allowing companies to scale their automation efforts as demand changes.

Moreover, the implementation of durable AGV platforms contributes to improved workplace safety. By automating repetitive and potentially hazardous tasks, businesses can reduce the risk of workplace accidents. This not only protects employees but also fosters a more productive working environment, where staff can focus on more strategic tasks rather than mundane transportation duties.

In summary, durable AGV platforms represent a vital investment for businesses operating in the logistics and warehousing industry. Their ability to enhance operational efficiency, reduce costs, and improve safety makes them an ideal solution for modern supply chain challenges. As the demand for automation continues to grow, the role of durable AGV platforms will only become more critical in driving success in the transportation and logistics sectors. By embracing this technology, companies can position themselves at the forefront of innovation and efficiency, ensuring they remain competitive in a dynamic market.

One of the primary advantages of durable AGV platforms is their ability to operate continuously, maximizing throughput while minimizing the need for human intervention. This is particularly beneficial in high-demand environments where the speed of operations is essential. Durable AGV platforms are designed to withstand harsh working conditions, ensuring that they can be relied upon for long periods without significant maintenance or downtime. This durability translates to a lower total cost of ownership, as businesses can avoid frequent repairs or replacements.

In addition to their robust construction, durable AGV platforms are equipped with advanced navigation technologies. These systems utilize a combination of sensors, cameras, and software to effectively navigate complex warehouse layouts. This not only enhances safety by reducing the risk of collisions but also improves the overall efficiency of material handling processes. Businesses can streamline their operations by integrating these platforms into their existing workflows, optimizing the movement of goods from storage to shipping areas.

Another important consideration is the flexibility offered by AGV platforms. They can be programmed to handle various loads and tasks, making them suitable for diverse applications within the logistics sector. From pallet transport to order picking, durable AGV platforms can adapt to different operational needs, allowing companies to scale their automation efforts as demand changes.

Moreover, the implementation of durable AGV platforms contributes to improved workplace safety. By automating repetitive and potentially hazardous tasks, businesses can reduce the risk of workplace accidents. This not only protects employees but also fosters a more productive working environment, where staff can focus on more strategic tasks rather than mundane transportation duties.

In summary, durable AGV platforms represent a vital investment for businesses operating in the logistics and warehousing industry. Their ability to enhance operational efficiency, reduce costs, and improve safety makes them an ideal solution for modern supply chain challenges. As the demand for automation continues to grow, the role of durable AGV platforms will only become more critical in driving success in the transportation and logistics sectors. By embracing this technology, companies can position themselves at the forefront of innovation and efficiency, ensuring they remain competitive in a dynamic market.

Related news

2025-07-28

Exploring the Benefits of Durable AGV Platforms in Logistics and Warehousing

In the rapidly evolving world of logistics and warehousing, the adoption of durable AGV platforms has become a crucial factor in enhancing efficiency and productivity. These automated systems have revolutionized the way goods are transported within facilities, offering a wide range of benefits for businesses in the transportation and logistics sectors.

One of the primary advantages of durable AGV

2025-07-23

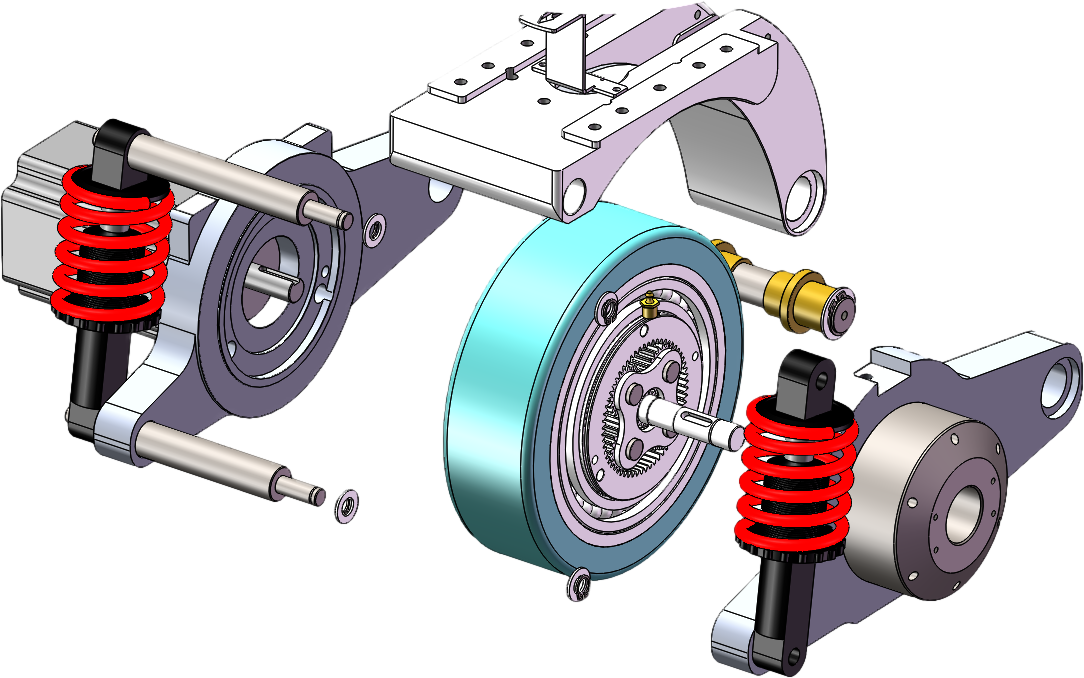

Why Quality Industrial Drive Wheels are Essential for Your Machinery

Why Quality Industrial Drive Wheels are Essential for Your Machinery

Table of Contents

1. Introduction to Industrial Drive Wheels

2. The Importance of Quality in Industrial Drive Wheels

3. Types of Industrial Drive Wheels

3.1 Rubber Drive Wheels

3.2 Polyurethane Drive Wheels

3.3 Metal Drive Wheels

4. Key F

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License