News Categories

Quality Industrial Drive Wheels: Innovations Transforming the Industry

Release time:

2025-12-18

Quality Industrial Drive Wheels: Innovations Transforming the Industry

Table of Contents

- Introduction to Industrial Drive Wheels

- The Importance of Quality in Industrial Drive Wheels

- Innovations in Industrial Drive Wheel Technology

- Materials Used in Drive Wheel Manufacturing

- Design Advances in Drive Wheels

- Applications of Quality Industrial Drive Wheels

- Safety and Compliance Standards

- The Future of Industrial Drive Wheels

- Conclusion

- Frequently Asked Questions

Introduction to Industrial Drive Wheels

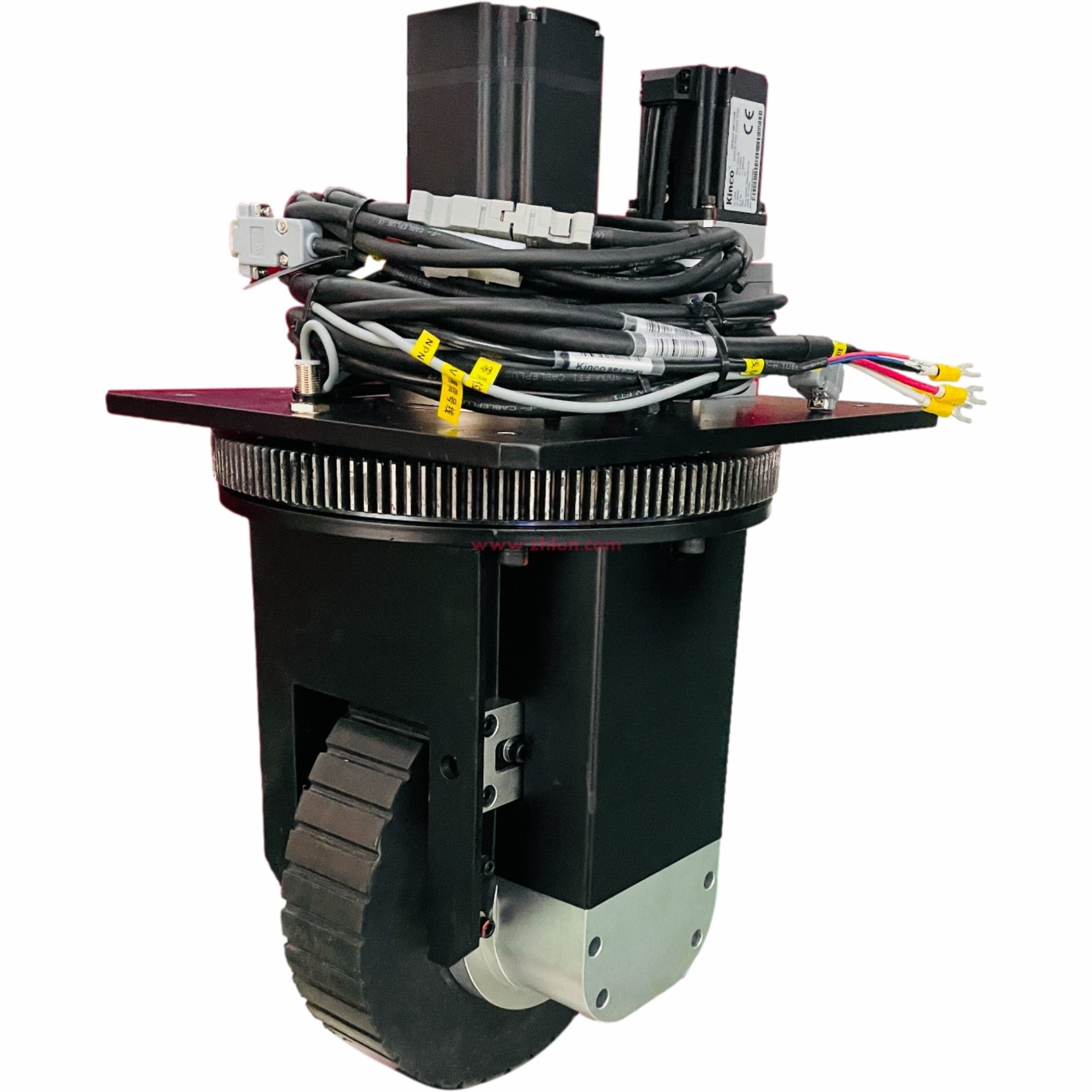

Industrial drive wheels play a crucial role in various sectors, from manufacturing to logistics. These wheels are essential components that facilitate the movement of heavy loads in diverse environments. With advancements in technology and a growing emphasis on efficiency, quality industrial drive wheels are evolving to meet the demands of modern industries.

The Importance of Quality in Industrial Drive Wheels

The demand for high-quality drive wheels is driven by several factors, including **efficiency**, **safety**, and **durability**. In industries where equipment reliability is crucial, subpar wheels can result in significant operational disruptions. High-quality drive wheels enhance performance, reduce downtime, and minimize maintenance costs.

### H3>Efficiency and Performance

Quality drive wheels are designed for optimal performance, ensuring smooth and efficient movement. High-precision engineering leads to reduced friction and wear, which translates into better fuel efficiency and lower operational costs.

### H3>Safety Considerations

Safety is paramount in any industrial setting. Poorly manufactured drive wheels can lead to accidents and injuries. Hence, investing in quality wheels is not just a smart business decision but also a commitment to employee well-being.

Innovations in Industrial Drive Wheel Technology

Innovations in industrial drive wheels are shaping the future of the industry. Manufacturers are embracing new technologies that enhance the performance and longevity of their products.

### H3>Smart Wheels

One of the most exciting innovations is the development of **smart wheels**. Equipped with sensors and connectivity features, these wheels can provide real-time data on performance metrics such as load weight, temperature, and wear levels. This data allows for predictive maintenance, reducing unexpected failures and enhancing efficiency.

### H3>3D Printing in Manufacturing

3D printing technology is revolutionizing the manufacturing process for drive wheels. This method allows for the production of complex geometries that traditional manufacturing cannot achieve. It also enables rapid prototyping, leading to faster product development cycles and reduced costs.

Materials Used in Drive Wheel Manufacturing

The choice of materials significantly influences the performance and durability of industrial drive wheels. Manufacturers are exploring various options to meet the specific requirements of different applications.

### H3>Polyurethane Wheels

Polyurethane is a popular material for industrial drive wheels due to its excellent wear resistance and shock absorption properties. These wheels are ideal for applications involving heavy loads and rough surfaces.

### H3>Steel and Aluminum Alloys

For high-load applications, steel and aluminum alloys are commonly used. These materials provide superior strength and durability, making them suitable for heavy-duty environments.

Design Advances in Drive Wheels

The design of industrial drive wheels has evolved significantly, incorporating ergonomic and functional considerations.

### H3>Customized Solutions

Many manufacturers now offer customized drive wheel solutions tailored to the specific needs of their clients. This customization might include size variations, tread patterns, and load capacities, ensuring optimal performance for unique applications.

### H3>Improved Tread Patterns

Innovative tread designs enhance traction and grip, improving safety and performance. Advanced computational modeling techniques enable manufacturers to optimize tread patterns for specific conditions, such as wet or uneven surfaces.

Applications of Quality Industrial Drive Wheels

Quality industrial drive wheels find applications across various sectors, each with specific requirements and challenges.

### H3>Material Handling

In warehouses and distribution centers, drive wheels are essential for material handling equipment like forklifts and pallet jacks. The right wheels ensure smooth operation and heavy load management.

### H3>Aerospace and Automotive

Within the aerospace and automotive industries, high-quality wheels are critical for conveying systems and assembly lines. Precision and reliability are non-negotiable in these sectors, where safety is paramount.

Safety and Compliance Standards

Adhering to safety and compliance standards is vital for manufacturers of industrial drive wheels. Organizations like OSHA and ANSI set guidelines to ensure that products are safe and reliable.

### H3>Regulatory Compliance

Manufacturers must stay updated with regulatory changes and ensure their products meet established safety standards. Regular audits and testing are essential to maintain compliance and safeguard users.

The Future of Industrial Drive Wheels

As technology continues to advance, the future of industrial drive wheels looks promising. Trends suggest increasing automation and the integration of artificial intelligence (AI) into wheel design and manufacturing processes.

### H3>Digital Twin Technology

Digital twin technology is emerging as a game-changer in the industry. This technology allows manufacturers to create virtual replicas of drive wheels to simulate performance under various conditions, leading to better designs and fewer failures.

### H3>Sustainability Initiatives

The focus on sustainability is reshaping material choices and manufacturing processes. Eco-friendly materials and energy-efficient production techniques are becoming increasingly important as industries strive to reduce their carbon footprint.

Conclusion

Quality industrial drive wheels are critical components that ensure the smooth operation of various industries. With innovations in technology, material science, and design, the future of drive wheels is bright. Companies that prioritize quality and invest in the latest advancements will not only enhance their operational efficiency but also ensure the safety and satisfaction of their workforce.

Frequently Asked Questions

What are industrial drive wheels made of?

Quality industrial drive wheels can be made from various materials, including polyurethane, steel, and aluminum alloys, depending on the application and load requirements.

How do I choose the right drive wheel for my application?

Consider factors such as load capacity, surface type, and environmental conditions. It's also important to consult with manufacturers for tailored solutions.

What are smart wheels?

Smart wheels are equipped with sensors that provide real-time data on performance metrics, allowing for predictive maintenance and enhanced efficiency.

How do innovations in drive wheels improve safety?

Innovations such as improved materials, designs, and smart technologies enhance traction and reduce the risk of accidents in industrial settings.

What is the future of industrial drive wheels?

The future includes advancements in automation, digital twin technology, and sustainability initiatives, leading to more efficient and eco-friendly manufacturing processes.

Related news

2025-12-18

Quality Industrial Drive Wheels: Innovations Transforming the Industry

Quality Industrial Drive Wheels: Innovations Transforming the Industry

Table of Contents

Introduction to Industrial Drive Wheels

The Importance of Quality in Industrial Drive Wheels

Innovations in Industrial Drive Wheel Technology

Materials Used in Drive Wheel Manufacturing

Design Advances in Drive Wheels

Applications of Quality Industrial Drive Wheels

Safety and Compl

2025-12-13

Unlocking the Power of the Best Motor Drive Wheels for Enhanced Performance

When it comes to enhancing the performance of vehicles, the significance of selecting the best motor drive wheel cannot be overstated. These wheels serve as a critical link between the motor and the ground, ensuring that power is effectively transmitted while optimizing control and functionality. So, what should professionals in the automotive and motorcycle industry consider when evaluating their

2025-12-08

The Science Behind New AGV Wheels and Their Impact on Drive Systems

The Science Behind New AGV Wheels and Their Impact on Drive Systems

As industries continue to evolve and adapt to modern demands, Automatic Guided Vehicles (AGVs) have become integral to logistics, manufacturing, and warehousing operations. Central to the functionality of these AGVs are their wheels, which play a crucial role in determining performance, efficiency, and safety. In this article, we

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License