The Science Behind New AGV Wheels and Their Impact on Drive Systems

Release time:

2025-12-08

The Science Behind New AGV Wheels and Their Impact on Drive Systems

As industries continue to evolve and adapt to modern demands, Automatic Guided Vehicles (AGVs) have become integral to logistics, manufacturing, and warehousing operations. Central to the functionality of these AGVs are their wheels, which play a crucial role in determining performance, efficiency, and safety. In this article, we will explore the advanced science behind new AGV wheels and their significant impact on drive systems, delving into materials, design innovations, and future trends.

Understanding Automatic Guided Vehicles (AGVs)

What Are AGVs?

Automatic Guided Vehicles (AGVs) are mobile robots used for transporting materials across various environments, including warehouses, factories, and distribution centers. Equipped with sensors and navigation systems, AGVs can operate autonomously, enhancing efficiency and reducing the need for human intervention. The design and functionality of AGVs are heavily influenced by the wheels they utilize, which affects speed, load capacity, and maneuverability.

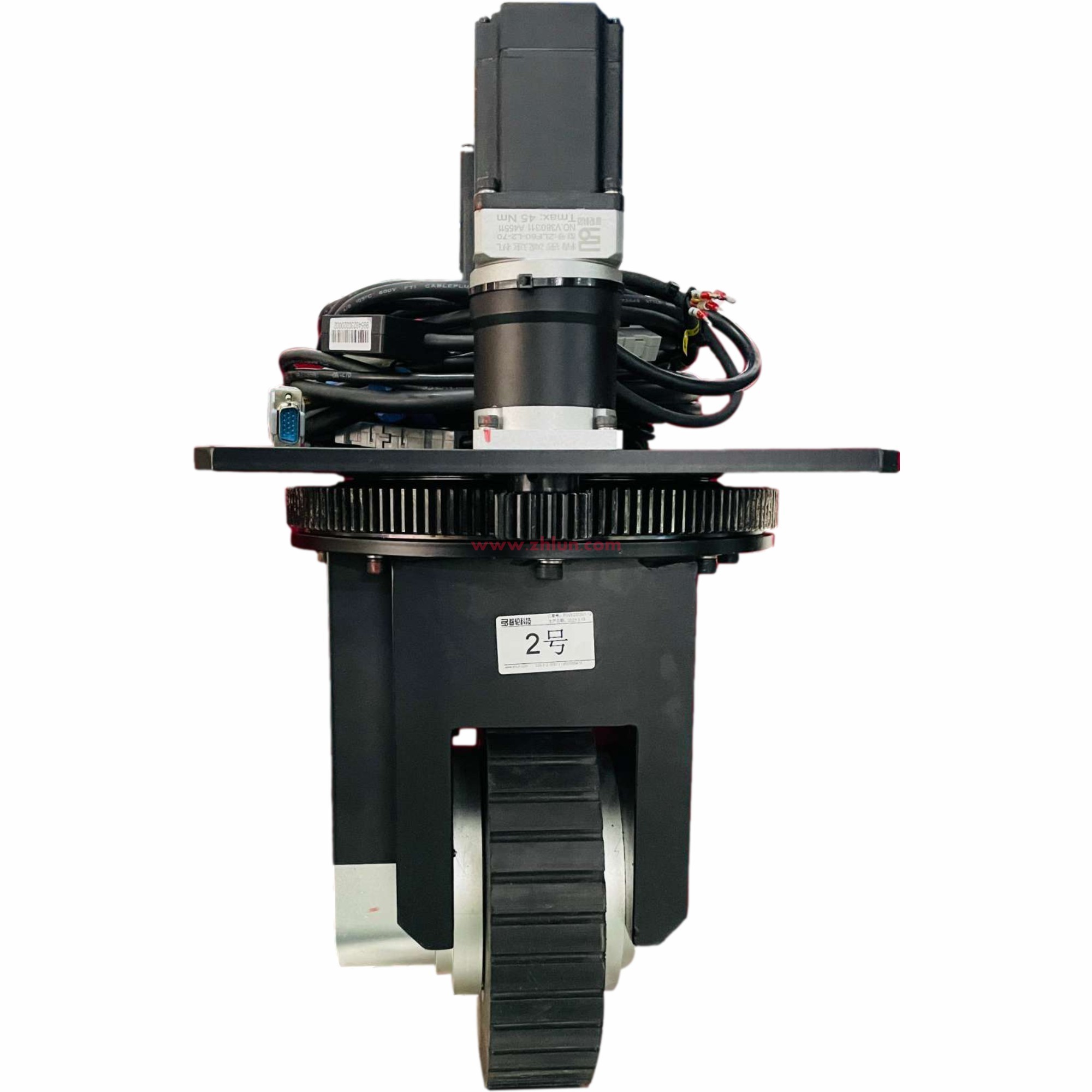

The Role of Wheels in Drive Systems

The wheels of an AGV are not merely components for motion; they are intricate mechanical systems that contribute to the overall performance of the vehicle. Factors such as traction, durability, and shock absorption are heavily reliant on the wheel design and materials used. Therefore, understanding the science behind AGV wheels is essential for optimizing drive systems.

Innovative Materials Used in AGV Wheels

Rubber Composites: The Backbone of AGV Wheels

The most common material used in AGV wheels is rubber due to its excellent grip and shock-absorbing properties. Recent advancements in rubber composites have led to the development of wheels that offer superior durability and resistance to wear and tear. These high-performance rubber compounds are engineered to withstand harsh environments, ensuring longevity and reliability.

Polyurethane Wheels: A Modern Alternative

Polyurethane wheels have gained popularity as an alternative to traditional rubber wheels. They provide enhanced performance attributes such as reduced rolling resistance and improved load-bearing capacity. Polyurethane's unique properties allow for more flexible designs, resulting in wheels that can adapt to varying surface conditions, making them ideal for diverse operational environments.

Benefits of Polyurethane Wheels

- Increased Durability: Polyurethane wheels exhibit high resistance to abrasion, prolonging their operational life.

- Noise Reduction: These wheels produce less noise during operation, contributing to a quieter working environment.

- Customizability: Polyurethane can be tailored for specific applications, providing options for hardness and tread patterns.

Design Features of Advanced AGV Wheels

Ergonomic Tread Patterns

The tread design of AGV wheels greatly influences traction and handling. Innovative tread patterns are engineered to optimize grip on various surfaces, reducing the likelihood of slippage and improving maneuverability. These designs are based on extensive research into material friction and ground contact dynamics.

Wheel Geometry and Load Distribution

Wheel geometry plays a pivotal role in the performance of AGVs. Engineers are continually refining the shape and size of AGV wheels to ensure optimal load distribution. Well-designed geometry allows for even weight distribution, minimizing the risk of damage to both the wheels and the surfaces they traverse.

Impact of Wheel Diameter on Performance

- Smaller Wheels: Offer better maneuverability in tight spaces, but may sacrifice speed and load capacity.

- Larger Wheels: Enhance speed and reduce rolling resistance, suitable for long-distance travel and heavy loads.

Technological Advancements in AGV Wheels

Smart Wheel Technology

Advancements in smart technology have paved the way for the integration of sensors and IoT capabilities into AGV wheels. These smart wheels can monitor performance metrics such as wear and tear, temperature, and pressure, providing real-time data that can be analyzed to improve efficiency and predict maintenance needs.

Eco-Friendly Innovations

As sustainability becomes a priority in industrial sectors, the development of eco-friendly AGV wheels is on the rise. Manufacturers are focusing on creating wheels using recyclable materials and environmentally friendly manufacturing processes, aligning with global efforts to reduce carbon footprints.

The Impact of New AGV Wheels on Drive Systems

Improved Efficiency and Productivity

The introduction of advanced AGV wheels has significantly enhanced the efficiency of drive systems. By optimizing traction and reducing friction, these wheels enable faster transport speeds and smoother operation, leading to increased productivity in warehouses and production lines.

Enhanced Safety Features

Safety is paramount in any automated system. New AGV wheels are designed with safety features such as better shock absorption and enhanced grip, reducing the risk of accidents and damage to goods. This is particularly critical in environments where AGVs operate alongside human workers.

Industry Applications of Advanced AGV Wheels

Warehousing and Distribution Centers

In warehousing and distribution settings, AGVs equipped with the latest wheel technology streamline the movement of goods. They reduce the time taken for transportation and minimize the chances of damage during transit.

Manufacturing and Assembly Lines

Within manufacturing environments, AGVs with advanced wheels facilitate the smooth movement of components and products along assembly lines, improving overall efficiency and reducing labor costs.

Case Study: A Leading Manufacturer's Transition to New AGV Wheels

Consider a prominent automotive manufacturer that transitioned to AGVs with cutting-edge wheel technology. The result was a 30% increase in production efficiency and a significant reduction in workplace accidents, demonstrating the profound impact of wheel design on operational success.

Future Trends in AGV Wheel Technology

Integration with Autonomous Navigation Systems

As autonomous navigation systems continue to advance, AGV wheels will likely see further enhancements in design and functionality. The combination of smart wheels and sophisticated navigation technology promises to revolutionize the efficiency and safety protocols of AGVs.

Continual Material Innovations

Research into new materials that offer better performance and environmental benefits is ongoing. Future AGV wheels may incorporate nanotechnology and smart polymers that can adapt to changing conditions, further improving their capabilities.

Frequently Asked Questions (FAQs)

1. What are the key benefits of using advanced AGV wheels?

Advanced AGV wheels offer numerous benefits, including improved efficiency, enhanced safety, better traction, and durability. These wheels significantly reduce operational costs and minimize downtime.

2. How do AGV wheels affect the overall performance of a drive system?

The performance of an AGV drive system is heavily reliant on the quality and design of the wheels. Factors such as material, tread design, and geometry directly influence speed, load capacity, and maneuverability.

3. Are there specific industries that benefit more from advanced AGV wheels?

Industries such as logistics, manufacturing, and automotive are particularly benefited by advanced AGV wheels due to their need for efficient material handling and transportation.

4. How often should AGV wheels be replaced?

The lifespan of AGV wheels depends on usage and the operating environment. Regular maintenance checks and monitoring of wear can help determine when a replacement is necessary.

5. Can AGV wheels be customized for specific applications?

Yes, many manufacturers offer customizable AGV wheels tailored to specific operational needs, including adjusting material hardness, size, and tread patterns to optimize performance.

Conclusion

In conclusion, the science behind new AGV wheels is an evolving field that holds immense potential for transforming drive systems across multiple industries. As we continue to innovate and integrate advanced materials and technologies, the impact of these wheels on efficiency, safety, and productivity will be profound. The future of AGVs is bright, and with continued advancements in wheel technology, industries can look forward to enhanced operational capabilities and sustainable practices for years to come.

Related news

2025-12-08

The Science Behind New AGV Wheels and Their Impact on Drive Systems

2025-12-03

Exploring Durable AGV Platforms for Enhanced Logistics Efficiency

2025-11-28

The Top Applications for Quality Industrial Drive Wheels in the Automotive Industry

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct