News Categories

Why Choose New AGV Wheels for Superior Handling? Unlocking the Future of Efficiency in Automated Guided Vehicles

Release time:

2025-10-09

Introduction to AGV Wheels and Their Importance in Handling

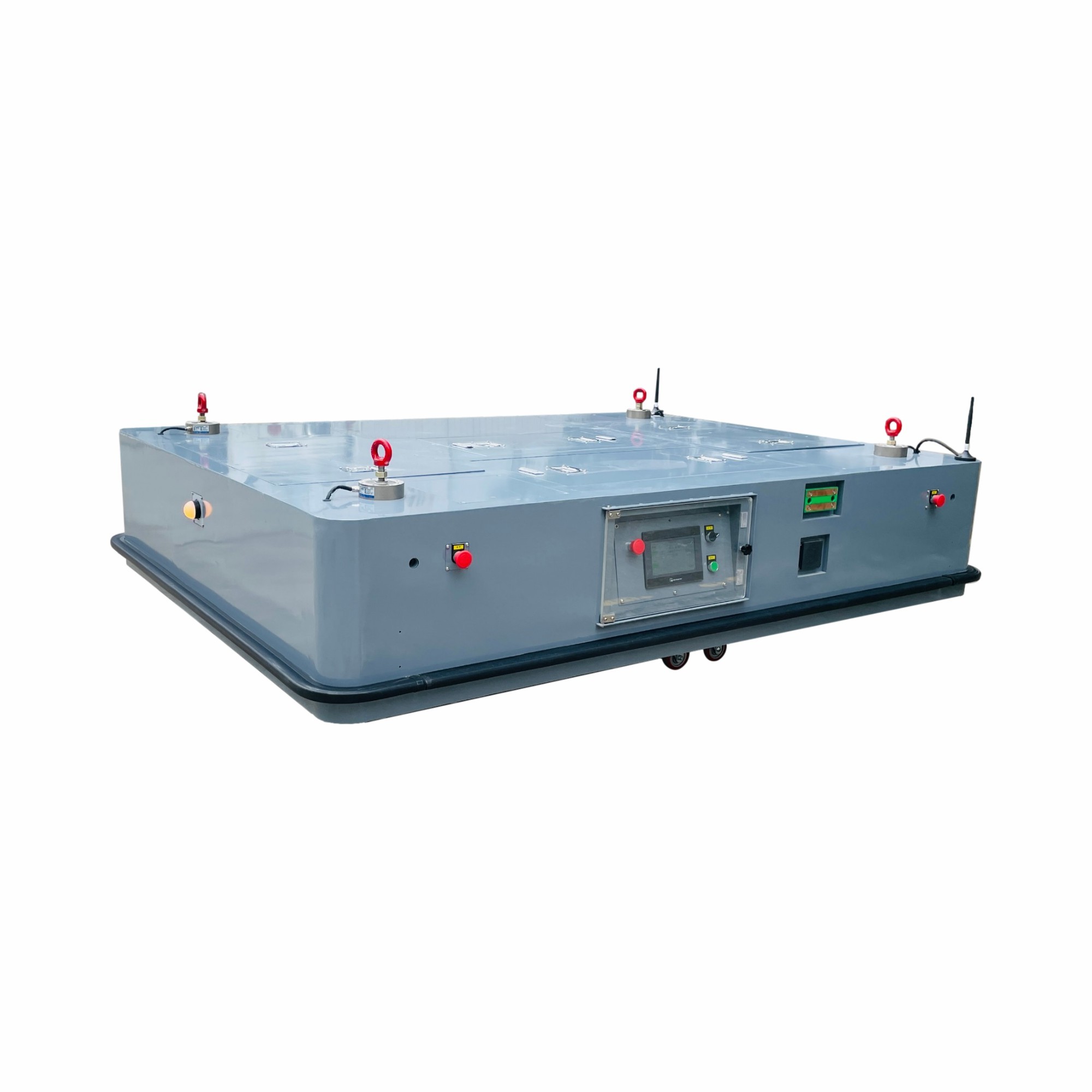

Automated Guided Vehicles (AGVs) are revolutionizing the way industries manage material handling and logistics. At the heart of every AGV lies a critical component: the wheels. The **wheels of an AGV** play an indispensable role in determining the vehicle's handling, speed, and overall operational efficiency. Upgrading to new AGV wheels can significantly enhance performance and ensure superior handling. In this article, we will explore the various aspects that make new AGV wheels a smart choice for any business looking to optimize their automated systems.

Understanding AGV Wheels: A Deep Dive

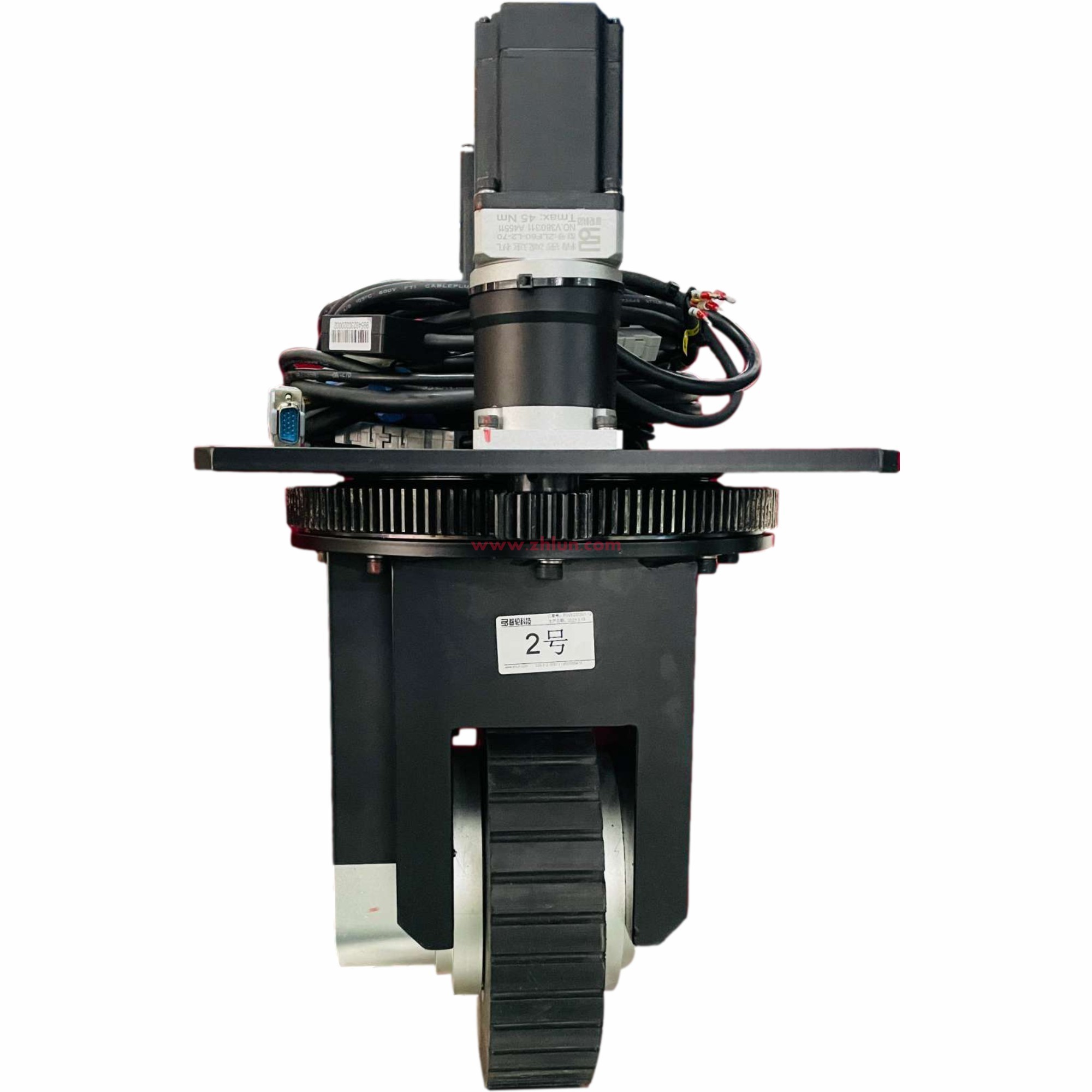

The Mechanics Behind AGV Wheels

AGV wheels are designed to support the weight of the vehicle while providing smooth movement across various surfaces. They are engineered with materials and designs that cater to specific environments, such as warehouses, manufacturing floors, or outdoor applications. Understanding the mechanics behind AGV wheels, including their construction and material composition, is vital to appreciate their impact on handling.

Types of AGV Wheels

There are several types of AGV wheels, including:

- Polyurethane Wheels: Known for their durability and shock absorption, ideal for indoor use.

- Rubber Wheels: Provide excellent traction and are suitable for uneven surfaces.

- Metal Wheels: Used for heavy-duty applications, offering high strength and longevity.

- Plastic Wheels: Lightweight and cost-effective, appropriate for lighter loads and smooth surfaces.

Each wheel type has distinct advantages and applications. Choosing the right wheel type can directly impact the AGV's handling capabilities.

Why Upgrade to New AGV Wheels?

Enhanced Performance

New AGV wheels are engineered with the latest technology, offering enhanced performance characteristics. With improved tread patterns and materials, these wheels provide better grip and reduced rolling resistance. This translates to faster speeds and more efficient operations, ultimately leading to increased productivity.

Improved Safety Features

Safety is paramount in any industrial environment. New AGV wheels are designed with safety in mind, featuring advanced braking systems and improved traction. These enhancements help minimize the risk of accidents, ensuring not only the well-being of employees but also the integrity of the cargo being transported.

Longer Lifespan

Investing in new AGV wheels can lead to significant cost savings over time. Modern wheels are crafted from high-quality materials that withstand wear and tear better than older models. This durability means fewer replacements, less downtime for maintenance, and a more reliable overall system.

Key Factors to Consider When Choosing New AGV Wheels

Load Capacity

One of the most critical factors in selecting AGV wheels is the load capacity. Each AGV has a specified weight limit, and the wheels must be able to support this weight comfortably. Overloading wheels can lead to premature wear and potential failure, so it’s essential to choose wheels that match or exceed the expected load.

Surface Compatibility

Different environments require different wheel types. Whether your AGV operates on smooth concrete, rough asphalt, or even outdoor terrains, selecting wheels compatible with these surfaces is crucial for optimal handling and performance.

Environmental Conditions

Consider the environmental conditions where your AGVs will operate. Factors such as temperature, moisture, and exposure to chemicals can affect wheel performance. New AGV wheels are often designed to withstand specific environmental challenges, ensuring longevity and reliability.

Benefits of Upgrading to New AGV Wheels

Cost Efficiency

While the initial investment in new AGV wheels may seem substantial, the long-term benefits can far outweigh the costs. Enhanced durability means fewer replacements, leading to lower operational costs over time.

Customization Options

Many manufacturers offer customization options for AGV wheels, allowing businesses to tailor features according to their specific needs. This could include variations in diameter, tread patterns, and material types to ensure optimal performance.

Boosted Efficiency

New AGV wheels can significantly boost operational efficiency. Improved handling and speed increase the overall throughput of goods, allowing businesses to meet customer demands more effectively.

Installation and Maintenance of New AGV Wheels

Installation Process

Installing new AGV wheels is a straightforward process when handled by trained professionals. The installation typically involves removing old wheels and replacing them with new ones, ensuring that all components are aligned correctly for optimal performance.

Routine Maintenance Tips

To maximize the lifespan of new AGV wheels, regular maintenance is crucial. Here are some tips to keep in mind:

- Conduct regular inspections to identify signs of wear or damage.

- Ensure proper alignment and tightness of the wheels.

- Clean the wheels regularly to remove debris that may affect performance.

- Monitor the load capacity and avoid overloading.

Real-World Applications of New AGV Wheels

Manufacturing Facilities

In manufacturing environments, AGVs equipped with new wheels enhance the movement of materials between production lines. Their superior handling allows for faster cycle times and reduced bottlenecks in the production process.

Warehousing and Distribution Centers

Warehouses benefit immensely from upgraded AGV wheels. Enhanced traction and speed contribute to efficient order fulfillment and inventory management, ultimately improving customer satisfaction.

Retail Environments

Even in retail settings, new AGV wheels can streamline operations. From stock replenishment to customer service functions, AGVs with advanced wheels facilitate smoother and more efficient workflows.

Frequently Asked Questions (FAQs)

1. How do I know if my AGV wheels need replacing?

Signs include excessive wear, reduced traction, unusual noises during operation, or visible damage to the wheel.

2. What is the average lifespan of AGV wheels?

The lifespan of AGV wheels varies based on usage, environment, and material but generally ranges from 1 to 5 years.

3. Can I mix different types of wheels on my AGV?

It's not advisable to mix wheel types, as this can lead to handling issues and uneven wear.

4. How do I choose the right wheel material for my AGV?

Consider the operational environment, load capacity, and specific handling requirements when selecting wheel materials.

5. Are custom AGV wheels worth the investment?

Custom AGV wheels can significantly enhance performance and efficiency tailored to specific operational needs, making them a worthwhile investment.

Conclusion

Upgrading to new AGV wheels is a vital step toward ensuring superior handling and overall operational efficiency in any automated system. By investing in advanced wheel technologies, businesses can enjoy improved performance, enhanced safety, and prolonged service life. The benefits of new AGV wheels extend beyond just the equipment; they contribute to a smoother, more reliable logistics operation that can adapt to the ever-changing demands of the market. For any organization looking to enhance their automated guided vehicles, the choice to upgrade is not only strategic but essential for future success.

Related news

2025-10-09

Introduction to AGV Wheels and Their Importance in Handling

Automated Guided Vehicles (AGVs) are revolutionizing the way industries manage material handling and logistics. At the heart of every AGV lies a critical component: the wheels. The **wheels of an AGV** play an indispensable role in determining the vehicle's handling, speed, and overall operational efficiency. Upgrading to new AGV wheels c

2025-10-04

Enhancing Efficiency with Durable AGV Platforms in Logistics

In the ever-evolving landscape of logistics and warehousing, the need for innovative solutions to enhance efficiency and productivity is paramount. Durable Automated Guided Vehicle (AGV) platforms have emerged as an essential component in this transformation, providing a reliable and effective means for goods transportation within warehouses and distribution centers.

Durable AGV platforms are engi

2025-09-29

Quality Industrial Drive Wheels: A Key Component for Reliable Performance

Quality Industrial Drive Wheels: A Key Component for Reliable Performance

Introduction to Industrial Drive Wheels

In the manufacturing and industrial sectors, the efficiency and reliability of machinery are paramount. One of the **most crucial components** that contribute to this reliability is the **industrial drive wheel**. These wheels are not merely functional parts; they play a significan

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License