News Categories

Quality Industrial Drive Wheels: A Key Component for Reliable Performance

Release time:

2025-09-29

Quality Industrial Drive Wheels: A Key Component for Reliable Performance

Introduction to Industrial Drive Wheels

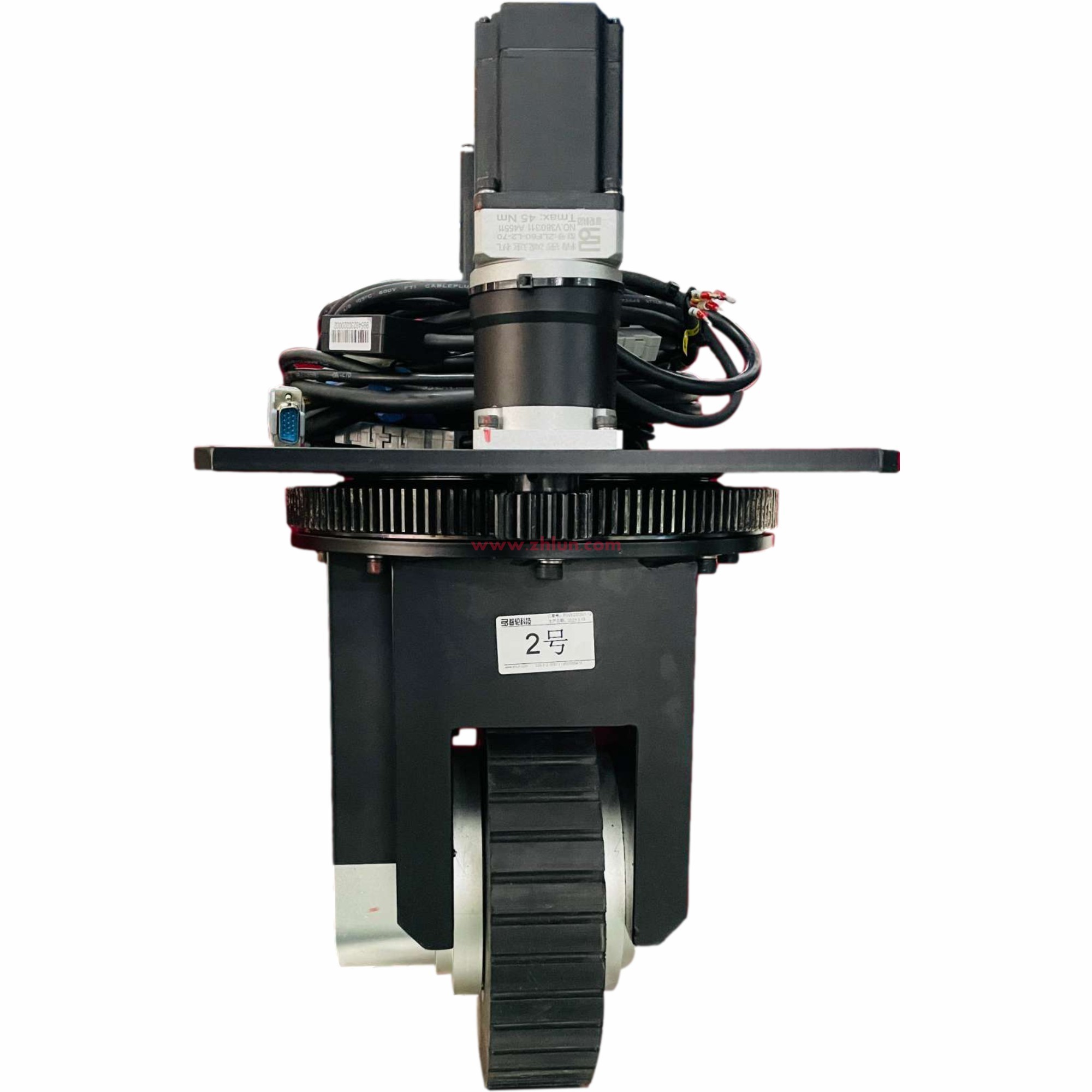

In the manufacturing and industrial sectors, the efficiency and reliability of machinery are paramount. One of the **most crucial components** that contribute to this reliability is the **industrial drive wheel**. These wheels are not merely functional parts; they play a significant role in the overall performance of various systems. This article will delve deep into the aspects of quality industrial drive wheels, highlighting their importance and the factors that make them indispensable in the industry.

What are Industrial Drive Wheels?

Industrial drive wheels are specialized wheels designed for heavy-duty applications, commonly used in machinery, vehicles, and conveyor systems. Unlike standard wheels, industrial drive wheels are engineered to withstand harsh conditions, high loads, and continual use. Their design, material, and construction play a pivotal role in determining their performance and longevity.

Types of Industrial Drive Wheels

Understanding the different types of industrial drive wheels is essential for selecting the right one for your needs. Here are the primary types:

1. Rubber Drive Wheels

Rubber drive wheels are popular for their **excellent grip** and shock-absorbing properties. They are ideal for applications where noise reduction and surface protection are crucial, such as in warehouses and assembly lines.

2. Polyurethane Drive Wheels

Polyurethane wheels offer remarkable durability and resistance to wear and tear. Their ability to handle heavy loads while maintaining performance makes them suitable for rigorous industrial environments.

3. Steel Drive Wheels

Steel drive wheels are the sturdiest option available, often used in heavy machinery and construction equipment. Their robust construction enables them to handle extreme loads and conditions.

4. Nylon Drive Wheels

Nylon wheels are lightweight and resistant to chemicals and moisture. They are often used in applications requiring high speed and low friction, such as automated guided vehicles (AGVs).

The Importance of Quality in Drive Wheels

When it comes to industrial operations, the quality of drive wheels cannot be overlooked. High-quality drive wheels offer several benefits:

Enhanced Performance

Quality drive wheels ensure that machinery operates smoothly and efficiently. They help maintain consistent speed and stability, which is vital for processes that require precision, such as assembly and packaging.

Increased Longevity

Investing in quality drive wheels can significantly extend the lifespan of your equipment. High-quality materials and construction methods reduce wear and tear, ultimately saving on replacement costs.

Improved Safety

Faulty or low-quality wheels can lead to accidents and equipment failures. Quality industrial drive wheels are designed with safety in mind, helping to prevent mishaps in the workplace.

Factors to Consider When Choosing Drive Wheels

Selecting the right industrial drive wheels involves several considerations. Understanding these factors ensures you make an informed choice that aligns with your operational needs.

Load Capacity

The load capacity of a drive wheel is a critical factor in its selection. Each wheel type is rated for specific load limits, so it is essential to choose a wheel that can support the weight of the machinery or loads being transported.

Surface Conditions

Consider the surface conditions in your operational environment. If your machinery operates on rough or uneven surfaces, wheels with higher durability and grip may be required.

Environmental Factors

Environmental conditions, such as exposure to chemicals, extreme temperatures, or moisture, affect the performance and longevity of drive wheels. Different materials offer varying levels of resistance to these factors.

Speed Requirements

The speed at which your machinery operates is also crucial. Wheels designed for high-speed applications may require specific materials and designs to reduce friction and ensure smooth operation.

Maintenance Tips for Industrial Drive Wheels

Proper maintenance of industrial drive wheels is essential for ensuring their longevity and reliability. Here are some key tips to keep your wheels in optimal condition:

Regular Inspections

Conduct regular inspections to identify any signs of wear or damage. Look for cracks, flat spots, or surface degradation, which may indicate the need for replacement.

Cleaning and Lubrication

Keep drive wheels clean and free of debris. Use appropriate cleaning solutions based on the wheel material. For wheels that require lubrication, ensure you use the recommended lubricants to prevent friction-related issues.

Monitoring Load Levels

Be vigilant about the load levels being placed on drive wheels. Overloading can lead to premature wear and failure, so always ensure that the load capacity is adhered to.

Alignment Checks

Misalignment can lead to uneven wear and hinder performance. Regularly check wheel alignment and make any necessary adjustments to ensure smooth operation.

Applications of Quality Industrial Drive Wheels

Quality industrial drive wheels find applications across various sectors. Some notable industries include:

Manufacturing

In manufacturing settings, drive wheels are used in conveyor systems, assembly lines, and automated machinery, ensuring efficient material handling and production processes.

Logistics and Warehousing

Drive wheels are essential in forklifts, pallet jacks, and automated guided vehicles. They facilitate the movement of goods, ensuring timely delivery and processing.

Construction

Heavy-duty drive wheels are critical in construction machinery, providing the necessary durability and strength to operate under extreme conditions.

Agriculture

In agricultural settings, drive wheels play a vital role in tractors and other machinery, enabling reliable performance in various farming tasks.

Choosing the Right Manufacturer for Industrial Drive Wheels

Selecting a reputable manufacturer is crucial for obtaining quality industrial drive wheels. Here are some factors to consider:

Experience and Reputation

Choose manufacturers with a proven track record in producing high-quality drive wheels. Research their reputation within the industry and seek testimonials from previous customers.

Quality Assurance Processes

Ensure that the manufacturer has strict quality control processes in place. This guarantees that the products meet the necessary standards and specifications.

Customization Options

Look for manufacturers that offer customization options to meet specific operational needs. Customized wheels can enhance performance and extend the lifespan of your equipment.

After-Sales Support

Evaluate the level of after-sales support provided by the manufacturer. This includes warranty options, maintenance assistance, and technical support for troubleshooting.

Conclusion

Quality industrial drive wheels are a fundamental component in ensuring the **reliable performance** of machinery across various industries. By understanding their importance, the factors influencing their selection, and the necessary maintenance practices, businesses can enhance operational efficiency and safety. Investing in high-quality drive wheels not only prolongs the lifespan of equipment but also contributes to a seamless workflow. As industries continue to evolve, the role of drive wheels will remain vital, underscoring the need for quality over quantity in industrial applications.

FAQs about Quality Industrial Drive Wheels

1. What materials are commonly used for industrial drive wheels?

Industrial drive wheels are typically made from materials such as rubber, polyurethane, steel, and nylon, each offering unique properties suited to specific applications.

2. How do I determine the right load capacity for drive wheels?

To determine the appropriate load capacity, assess the weight of the machinery or items being transported and refer to the manufacturer's specifications for the wheel type.

3. How often should industrial drive wheels be inspected?

Regular inspections should be conducted at least once a month, or more frequently in high-use environments, to identify any signs of wear or damage.

4. Can I use the same type of drive wheel for different applications?

While some drive wheels may be versatile, it is best to select wheels specifically designed for each application based on load, speed, and surface conditions.

5. What are the signs that my drive wheels need replacement?

Signs of wear include visible cracks, flat spots, noise during operation, and decreased performance. If you notice any of these issues, it may be time to replace the wheels.

Related news

2025-09-29

Quality Industrial Drive Wheels: A Key Component for Reliable Performance

Quality Industrial Drive Wheels: A Key Component for Reliable Performance

Introduction to Industrial Drive Wheels

In the manufacturing and industrial sectors, the efficiency and reliability of machinery are paramount. One of the **most crucial components** that contribute to this reliability is the **industrial drive wheel**. These wheels are not merely functional parts; they play a significan

2025-09-24

Unlocking the Potential of the Best Motor Drive Wheel: A Comprehensive Guide

In the realm of automotive and accessory systems, the choice of the best motor drive wheel is a critical factor that can significantly impact the overall performance of your vehicle. Motor drive wheels play a pivotal role in ensuring that power generated by the engine is effectively transferred to the wheels, providing smooth acceleration, improved handling, and enhanced vehicle responsiveness.

Wh

2025-09-19

The Future of Drive Systems: Innovations in New AGV Wheel Technology

The Future of Drive Systems: Innovations in New AGV Wheel Technology

Table of Contents

1. Introduction to AGV Wheel Technology

2. Historical Development of Drive Systems

3. Current Technologies in AGV Wheels

4. Innovations in Materials for AGV Wheels

5. Smart Technology Integration in Drive Systems

6. Enhanced Performance Features of New AGV Wheels

7. Sustainability an

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License