News Categories

The Future of Drive Systems: Innovations in New AGV Wheel Technology

Release time:

2025-09-19

The Future of Drive Systems: Innovations in New AGV Wheel Technology

Table of Contents

- 1. Introduction to AGV Wheel Technology

- 2. Historical Development of Drive Systems

- 3. Current Technologies in AGV Wheels

- 4. Innovations in Materials for AGV Wheels

- 5. Smart Technology Integration in Drive Systems

- 6. Enhanced Performance Features of New AGV Wheels

- 7. Sustainability and Efficiency in AGV Design

- 8. Future Trends in AGV Wheel Technology

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to AGV Wheel Technology

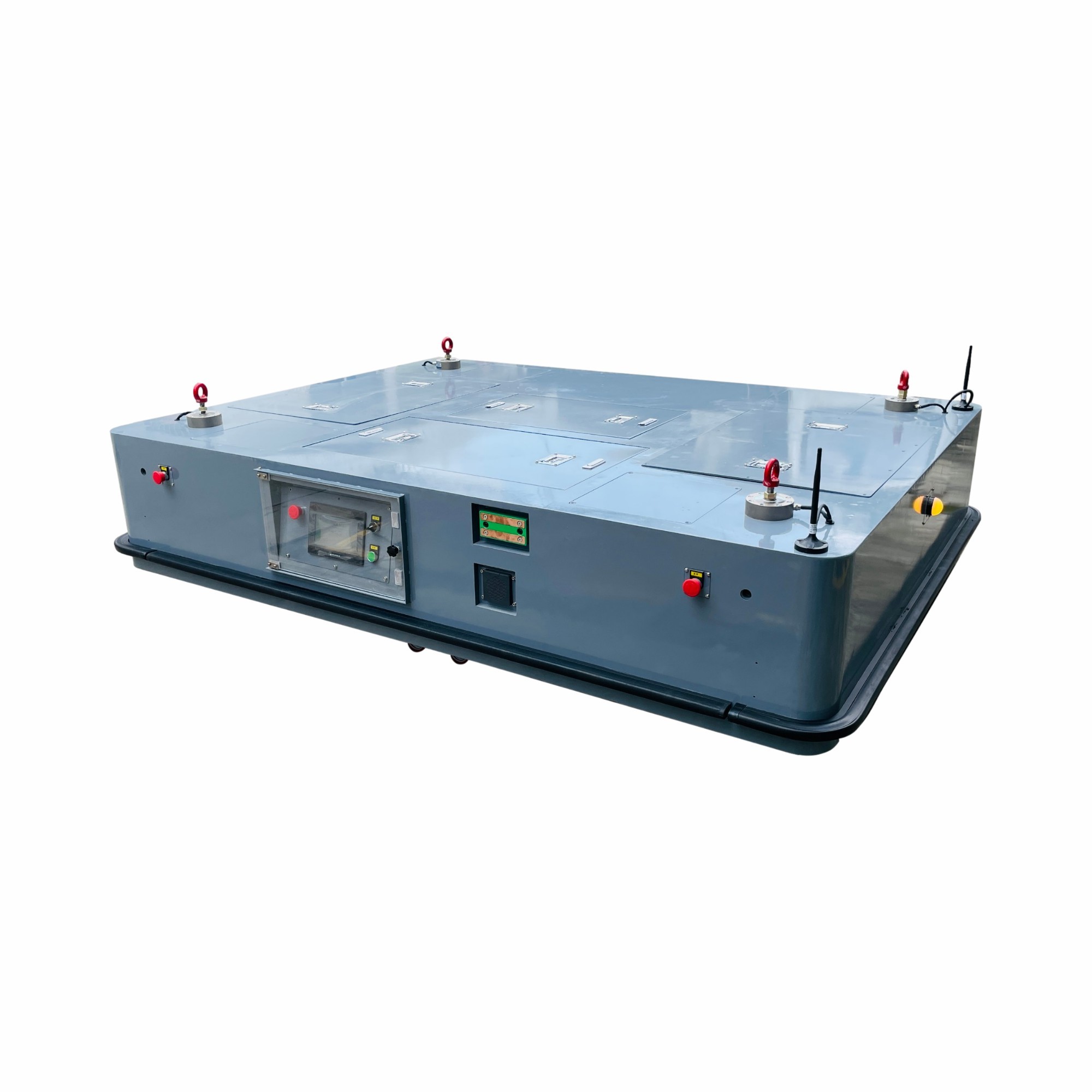

Automated Guided Vehicles (AGVs) are reshaping the landscape of logistics and transportation within industries. The development of advanced **drive systems**, particularly in **AGV wheel technology**, is at the heart of this transformation. AGVs use various forms of wheels to navigate environments autonomously, making innovations in this area crucial for enhancing operational efficiency and safety. This article delves into the latest advancements in AGV wheel technology, exploring how these innovations are setting the stage for a new era in drive systems.

2. Historical Development of Drive Systems

The origins of drive systems can be traced back to the early 20th century when automation was first introduced in manufacturing. As technology progressed, the evolution of **AGV systems** began to take shape in the 1950s, allowing for simplified material handling. Early models primarily relied on basic wheeled structures, limiting their functionality and flexibility. However, as demand for efficiency grew, significant improvements were made in wheel design and materials. Innovations such as **polyurethane wheels** and **magnetic navigation systems** emerged, allowing AGVs to operate in more complex environments.

3. Current Technologies in AGV Wheels

Today’s AGV wheels incorporate advanced technologies that enhance their performance and adaptability. Some of the most notable current technologies include:

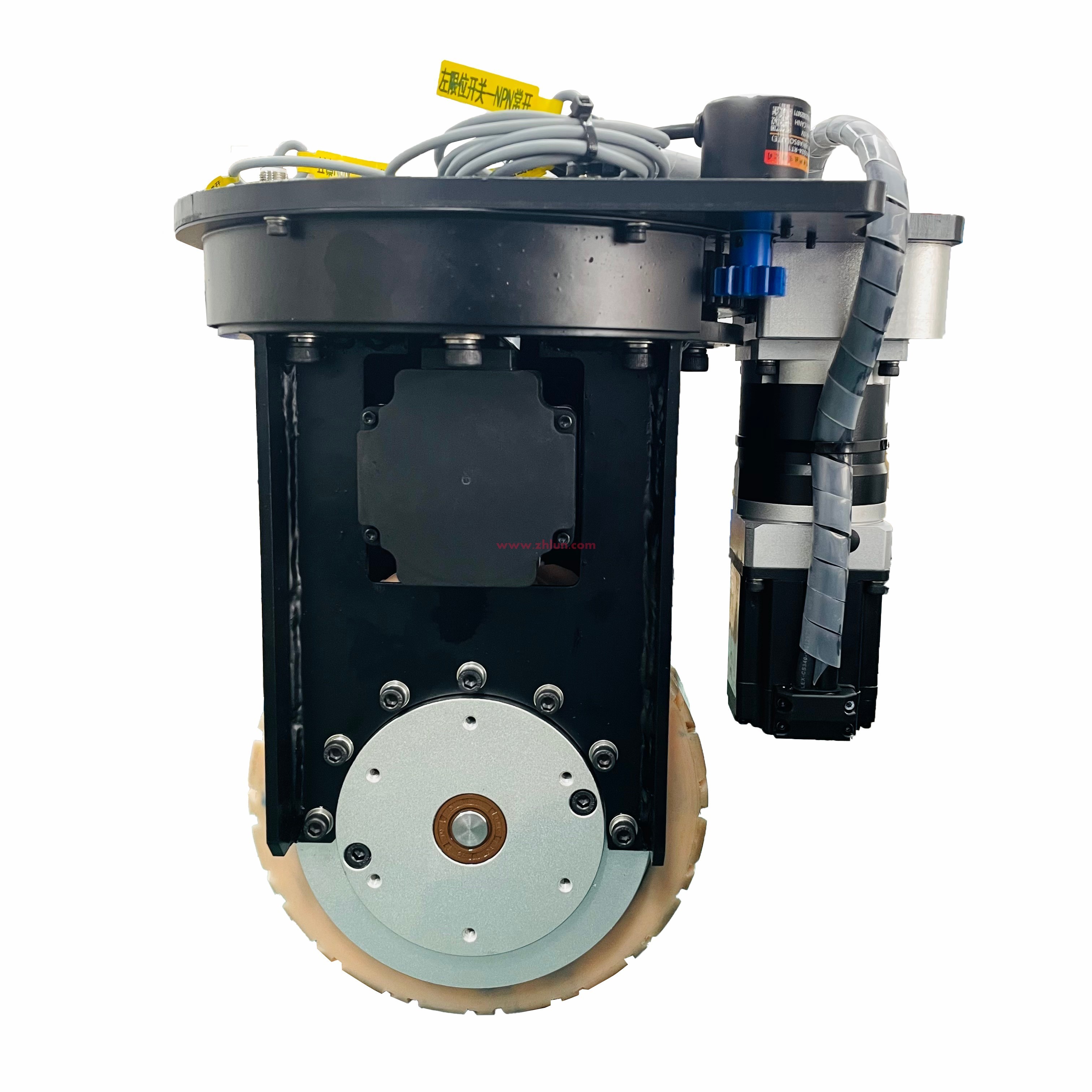

3.1. Polyurethane and Rubber Wheel Designs

Polyurethane wheels are favored for their durability and resistance to wear and tear. Rubber wheels, on the other hand, provide excellent grip and shock absorption, making them ideal for uneven surfaces. Many modern AGVs combine these materials to achieve optimal performance.

3.2. Caster Wheels for Enhanced Maneuverability

Caster wheels facilitate better agility, enabling AGVs to navigate tight corners and complex layouts within warehouses and factories. This enhances the overall efficiency of material handling processes.

3.3. Wheel Sensors and Feedback Systems

Equipping AGV wheels with sensors allows for real-time monitoring of wheel performance and status. Feedback systems ensure that any anomalies are detected and addressed promptly, improving the longevity and reliability of the drive system.

4. Innovations in Materials for AGV Wheels

The quest for improved AGV wheel technology continues to drive innovations in materials. Today’s research focuses on lightweight yet durable composites that can withstand heavy loads while offering superior performance.

4.1. Advanced Composite Materials

Materials such as carbon fiber and advanced polymers are now being used to construct AGV wheels. These materials provide a significant reduction in weight without compromising strength, allowing for more energy-efficient operations.

4.2. Self-Healing Materials

An exciting innovation in wheel technology is the development of self-healing materials. These materials can automatically repair minor damages, extending the operational life of AGV wheels and reducing maintenance costs.

5. Smart Technology Integration in Drive Systems

The integration of smart technologies is a game-changer for AGV systems. From artificial intelligence to Internet of Things (IoT) connectivity, smart technologies are transforming how AGVs operate.

5.1. AI-Powered Navigation Systems

AI algorithms enhance the navigation capabilities of AGVs, allowing them to adapt to changing environments and optimize their routes in real-time. This not only improves efficiency but also reduces energy consumption.

5.2. IoT Connectivity

IoT technology enables seamless communication between AGVs and other systems within the supply chain. This connectivity allows for better tracking and management of inventory, ensuring that goods are transported more efficiently.

6. Enhanced Performance Features of New AGV Wheels

Recent innovations have resulted in AGV wheels that offer enhanced performance through various features.

6.1. Noise Reduction Technologies

New wheel designs incorporate noise reduction technologies that significantly lower operational noise levels. This is particularly important in environments where noise pollution must be minimized.

6.2. Increased Load Capacity

Advanced engineering techniques have led to improvements in load capacity. Modern AGV wheels are designed to handle heavier loads while maintaining stability and maneuverability.

7. Sustainability and Efficiency in AGV Design

As industries shift towards sustainable practices, the demand for eco-friendly AGV solutions is increasing. Innovations in wheel technology play a crucial role in this transition.

7.1. Energy-Efficient Drive Systems

The latest AGV wheels are designed to work with energy-efficient motors, reducing overall energy consumption. By optimizing the interaction between wheels and motors, manufacturers can enhance the sustainability of AGV systems.

7.2. Recyclable Materials

Utilizing recyclable materials in wheel production not only minimizes environmental impact but also appeals to consumers who prioritize sustainability. Companies are increasingly adopting materials that can be repurposed at the end of their lifecycle.

8. Future Trends in AGV Wheel Technology

The future of AGV wheel technology is bright, with several trends on the horizon.

8.1. Autonomous Operations

As AGVs become more sophisticated, the move towards fully autonomous operations will accelerate. This includes advanced pathfinding and decision-making capabilities, further reducing the need for human intervention.

8.2. Customization and Modular Designs

The demand for customized AGV solutions will drive innovations in modular wheel designs. This allows companies to tailor AGVs to specific operational needs, enhancing versatility and efficiency.

9. Conclusion

The landscape of drive systems is evolving rapidly, driven by innovations in AGV wheel technology. With advancements in materials, smart technology integration, and a focus on sustainability, the future holds immense potential for enhancing efficiency and performance in automated logistics. As industries embrace these innovations, we can expect AGVs to play a pivotal role in streamlining operations, reducing costs, and fostering sustainable practices.

10. Frequently Asked Questions

1. What are AGVs, and how do they work?

AGVs, or Automated Guided Vehicles, are mobile robots that transport materials throughout a facility without human intervention. They navigate using various technologies such as magnetic strips, lasers, or visual markers.

2. What materials are commonly used in AGV wheels?

Common materials used in AGV wheels include polyurethane, rubber, and advanced composites such as carbon fiber.

3. How do smart technologies enhance AGV operations?

Smart technologies, such as AI and IoT, improve AGV navigation, monitoring, and communication, leading to more efficient operations and better integration within supply chain systems.

4. What are the benefits of using self-healing materials in AGV wheels?

Self-healing materials extend the operational life of AGV wheels by automatically repairing minor damages, reducing maintenance costs and downtime.

5. How is sustainability addressed in new AGV wheel technologies?

Sustainability is addressed through the use of energy-efficient designs and recyclable materials, aligning with the growing emphasis on eco-friendly practices in industry.

Related news

2025-09-19

The Future of Drive Systems: Innovations in New AGV Wheel Technology

The Future of Drive Systems: Innovations in New AGV Wheel Technology

Table of Contents

1. Introduction to AGV Wheel Technology

2. Historical Development of Drive Systems

3. Current Technologies in AGV Wheels

4. Innovations in Materials for AGV Wheels

5. Smart Technology Integration in Drive Systems

6. Enhanced Performance Features of New AGV Wheels

7. Sustainability an

2025-09-14

Exploring the Benefits and Features of Durable AGV Platforms in Logistics

Automated Guided Vehicles (AGVs) have revolutionized the logistics and transportation sectors, particularly concerning cargo handling and warehousing operations. Among the various types of AGV platforms, durable AGV platforms stand out due to their ability to withstand demanding environments and rigorous operational conditions. This article explores the essential features and benefits of durable A

2025-09-11

Unveiling the Best Motor Drive Wheel Options for Enhanced Performance

When it comes to the world of automotive and motorcycle parts, particularly in the domain of drive systems and drive accessories, one critical component stands out: the motor drive wheel. Understanding the best motor drive wheel options available can significantly impact the overall performance, efficiency, and responsiveness of your vehicle. Here, we delve into the various factors that contribute

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License