News Categories

How New AGV Wheels Enhance Efficiency in Automotive Systems

Release time:

2025-06-23

How New AGV Wheels Enhance Efficiency in Automotive Systems

Table of Contents

- 1. Introduction: The Role of AGV Wheels in Automotive Systems

- 2. Understanding AGV Wheels: Design and Functionality

- 3. Technological Advancements in AGV Wheel Design

- 4. Benefits of New AGV Wheels in Automotive Systems

- 5. Impact on Operational Efficiency and Productivity

- 6. Case Studies: Real-World Applications of Advanced AGV Wheels

- 7. Future Trends in AGV Wheel Technology

- 8. Conclusion

- 9. FAQs

1. Introduction: The Role of AGV Wheels in Automotive Systems

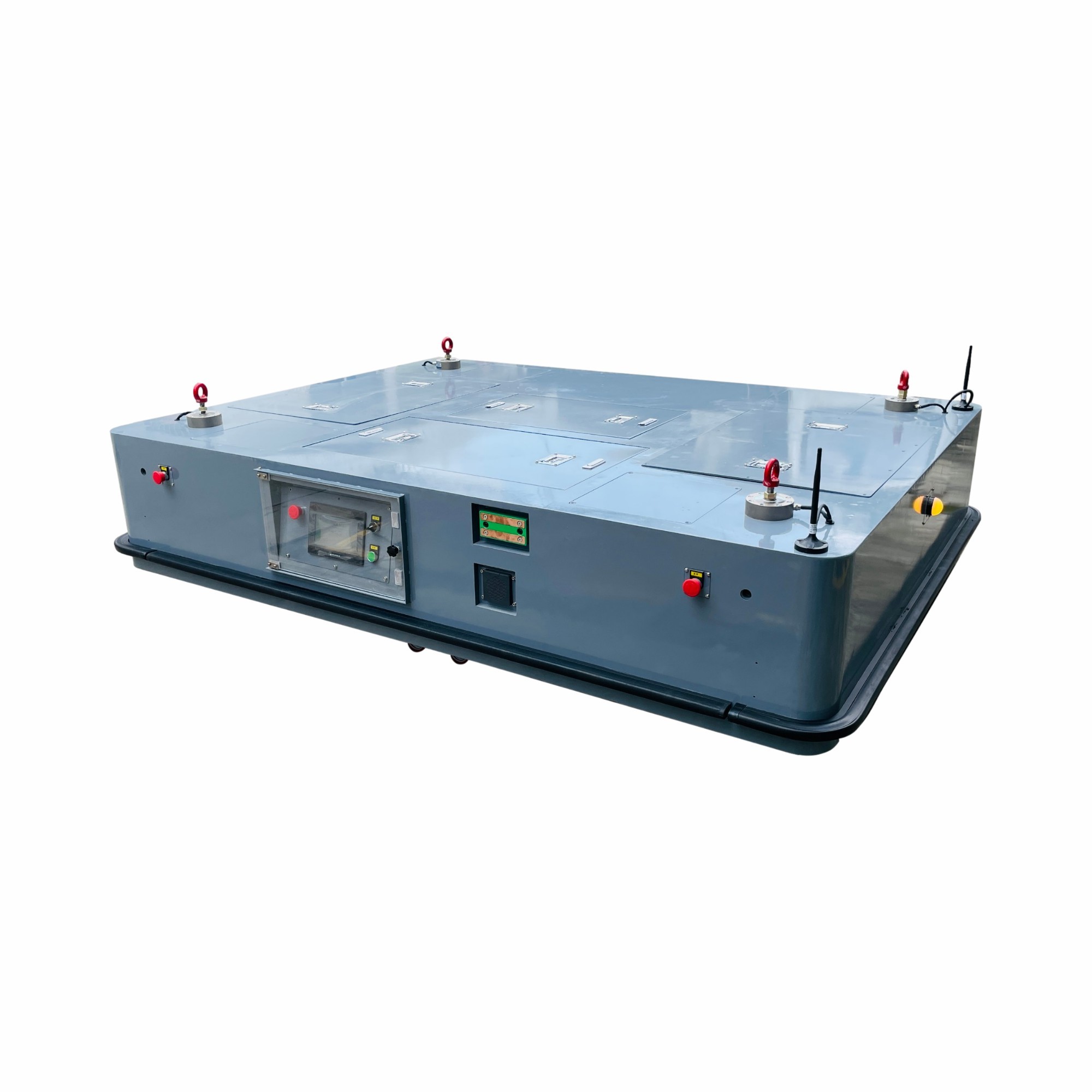

In the fast-paced automotive industry, efficiency is paramount. Automated Guided Vehicles (AGVs) have emerged as a game-changing solution, streamlining processes and enhancing productivity. At the core of AGV technology are the **wheels** that facilitate movement. Recent innovations in AGV wheel design have made them more efficient, durable, and adaptable to various operational environments. This article explores how these new AGV wheels are revolutionizing automotive systems by improving efficiency.

2. Understanding AGV Wheels: Design and Functionality

AGV wheels are engineered to support the unique requirements of automated vehicles. They possess several features that distinguish them from conventional wheels:

2.1 Wheel Construction and Materials

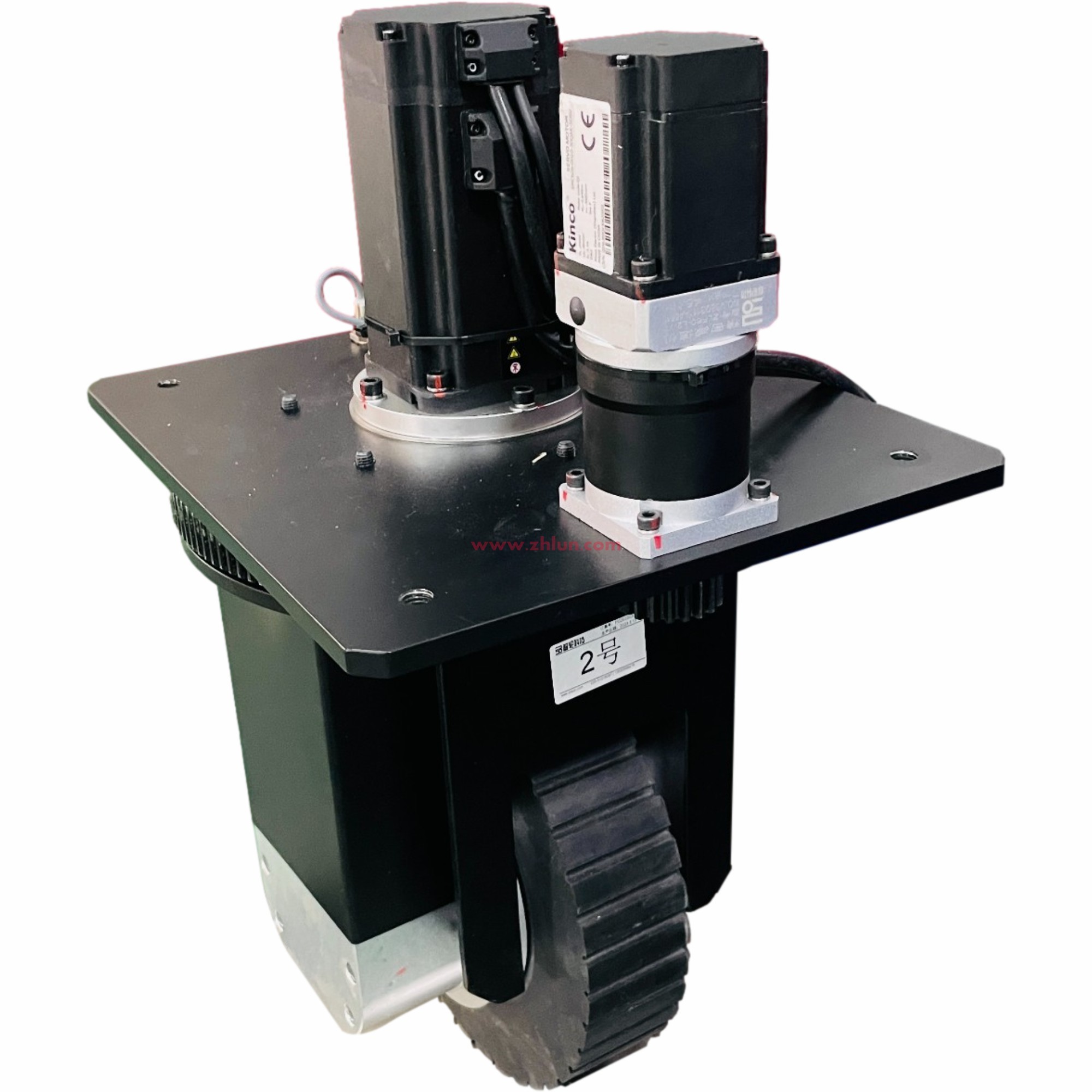

Modern AGV wheels are constructed using a combination of high-strength materials such as polyurethane, rubber, and specialized composites. These materials enhance durability and reduce wear, ensuring a longer lifespan.

2.2 Types of AGV Wheels

There are several types of AGV wheels, including:

- **Drive Wheels:** These provide propulsion and are typically motorized.

- **Idler Wheels:** Used for stability and support, these wheels guide the AGV smoothly along its path.

- **Steering Wheels:** These allow for directional movement and precise navigation.

2.3 Wheel Size and Design Considerations

The size and design of AGV wheels are critical to their performance. Larger wheels can navigate obstacles more easily, while smaller wheels may be better suited for tighter turns and confined spaces. Advanced designs also incorporate features like tread patterns that enhance traction and reduce slippage.

3. Technological Advancements in AGV Wheel Design

Technological advancements have driven significant improvements in AGV wheel design, leading to enhanced performance and reliability.

3.1 Smart Wheel Technology

Integrating sensors within AGV wheels enables real-time monitoring of performance metrics such as speed, load weight, and wear. This data is invaluable for predictive maintenance and operational optimization.

3.2 Improved Traction and Stability

Recent innovations in tread design have significantly improved traction. This enhancement minimizes the risk of slipping, especially in dynamic environments such as automotive assembly lines.

3.3 Noise Reduction Features

New materials and designs focus on reducing noise pollution, creating a quieter working environment. This is particularly important in facilities where human workers and AGVs coexist.

4. Benefits of New AGV Wheels in Automotive Systems

The introduction of advanced AGV wheels offers numerous benefits that directly impact automotive systems.

4.1 Increased Efficiency and Productivity

With superior design and enhanced capabilities, new AGV wheels reduce downtime and increase the efficiency of material handling processes, allowing manufacturers to produce more in less time.

4.2 Cost Savings

Investing in high-quality AGV wheels translates to long-term cost savings. Reduced maintenance costs, decreased wear and tear, and enhanced reliability lead to lower operational expenses.

4.3 Enhanced Safety Protocols

New AGV wheels are designed with safety in mind, minimizing the risk of accidents and injuries in the workplace. This is achieved through features like anti-slip designs and real-time monitoring systems that alert operators to potential hazards.

5. Impact on Operational Efficiency and Productivity

AGV wheels play a crucial role in enhancing operational efficiency across various automotive sectors.

5.1 Streamlining Manufacturing Processes

In automotive manufacturing, AGVs equipped with the latest wheel technologies can efficiently transport parts and materials throughout the production line, ensuring seamless workflow and reducing bottlenecks.

5.2 Optimizing Warehouse Logistics

In warehouses, advanced AGV wheels facilitate faster and more reliable transport of inventory, improving order fulfillment rates and reducing lead times.

5.3 Adaptive Solutions for Diverse Environments

New AGV wheel technologies are versatile enough to adapt to different surfaces and conditions, ensuring consistent performance whether in a manufacturing plant, warehouse, or assembly line.

6. Case Studies: Real-World Applications of Advanced AGV Wheels

Several automotive manufacturers have adopted new AGV wheel technologies with impressive results.

6.1 Case Study: Automotive Assembly Line Automation

A major automotive manufacturer implemented advanced AGV wheels in its assembly line, resulting in a 30% increase in production speed and a 20% reduction in operational costs. The smart wheel technology enabled real-time monitoring, allowing for immediate adjustments and minimizing downtime.

6.2 Case Study: Warehouse Efficiency Enhancement

In a large automotive parts warehouse, the introduction of new AGV wheels led to a 40% improvement in inventory management. The enhanced traction and stability of the wheels enabled AGVs to navigate challenging layouts, ensuring timely delivery of parts to assembly lines.

7. Future Trends in AGV Wheel Technology

The future of AGV wheel technology is poised for further innovation, driven by advancements in robotics and artificial intelligence.

7.1 Integration of AI and Machine Learning

Future AGV wheels will likely incorporate AI-driven analytics to enhance decision-making processes, further optimizing routes and load management.

7.2 Sustainable Materials and Eco-Friendly Solutions

As sustainability becomes a critical focus in the automotive industry, the use of eco-friendly materials in AGV wheel production will likely increase, reducing the environmental footprint of manufacturing operations.

7.3 Enhanced Customization Options

Manufacturers will increasingly seek customized AGV wheel solutions tailored to specific operational needs, driving innovation in design and functionality.

8. Conclusion

The introduction of new AGV wheels has significantly enhanced efficiency in automotive systems. With their advanced materials, smart technologies, and design innovations, these wheels are transforming how automotive manufacturers operate. As we look to the future, the continued evolution of AGV wheel technology will undoubtedly play a pivotal role in driving efficiency, productivity, and safety in the automotive industry.

9. FAQs

What are AGV wheels?

AGV wheels are specialized wheels designed for Automated Guided Vehicles, enabling them to navigate and transport materials within manufacturing and warehouse environments efficiently.

How do new AGV wheels improve efficiency?

New AGV wheels enhance efficiency through improved traction, durability, reduced noise, and smart technologies that provide real-time monitoring and data analysis.

What materials are used in AGV wheel construction?

AGV wheels are typically made from high-strength materials such as polyurethane, rubber, and specialized composites to ensure durability and performance.

Can AGV wheels adapt to different environments?

Yes, advanced AGV wheels are designed to adapt to various surfaces and conditions, making them versatile for different operational environments.

What impact do AGV wheels have on safety?

New AGV wheels enhance workplace safety by minimizing the risk of accidents through features like anti-slip designs and real-time monitoring systems that alert operators to potential hazards.

Related news

2025-06-23

How New AGV Wheels Enhance Efficiency in Automotive Systems

How New AGV Wheels Enhance Efficiency in Automotive Systems

Table of Contents

1. Introduction: The Role of AGV Wheels in Automotive Systems

2. Understanding AGV Wheels: Design and Functionality

3. Technological Advancements in AGV Wheel Design

4. Benefits of New AGV Wheels in Automotive Systems

5. Impact on Operational Efficiency and Productivity

6. Case Studies: Real-

2025-06-18

Exploring the Benefits of Durable AGV Platforms in Logistics and Warehousing

In the fast-paced world of logistics and warehousing, the need for efficient transportation solutions is paramount. Durable Automated Guided Vehicle (AGV) platforms have emerged as a key technology, providing businesses with reliable and effective ways to streamline their operations. These platforms are designed to transport goods safely and efficiently within warehouses and production facilities,

2025-06-13

How Quality Industrial Drive Wheels Enhance Performance in Automotive Systems

How Quality Industrial Drive Wheels Enhance Performance in Automotive Systems

Table of Contents

Introduction to Industrial Drive Wheels

The Importance of Quality in Drive Wheels

Types of Industrial Drive Wheels

Materials Used in Drive Wheel Manufacturing

The Design Process of Industrial Drive Wheels

Performance Metrics of Drive Wheels

Maintenance of Drive Wheels for Optimal Performa

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 8, Longhe Westroad,

Longgui, Taihe Town, Guangzhou, Guangdong.China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License