News Categories

How Quality Industrial Drive Wheels Enhance Performance in Automotive Systems

Release time:

2025-06-13

How Quality Industrial Drive Wheels Enhance Performance in Automotive Systems

Table of Contents

- Introduction to Industrial Drive Wheels

- The Importance of Quality in Drive Wheels

- Types of Industrial Drive Wheels

- Materials Used in Drive Wheel Manufacturing

- The Design Process of Industrial Drive Wheels

- Performance Metrics of Drive Wheels

- Maintenance of Drive Wheels for Optimal Performance

- Recent Innovations in Drive Wheel Technology

- Conclusion

- FAQs

Introduction to Industrial Drive Wheels

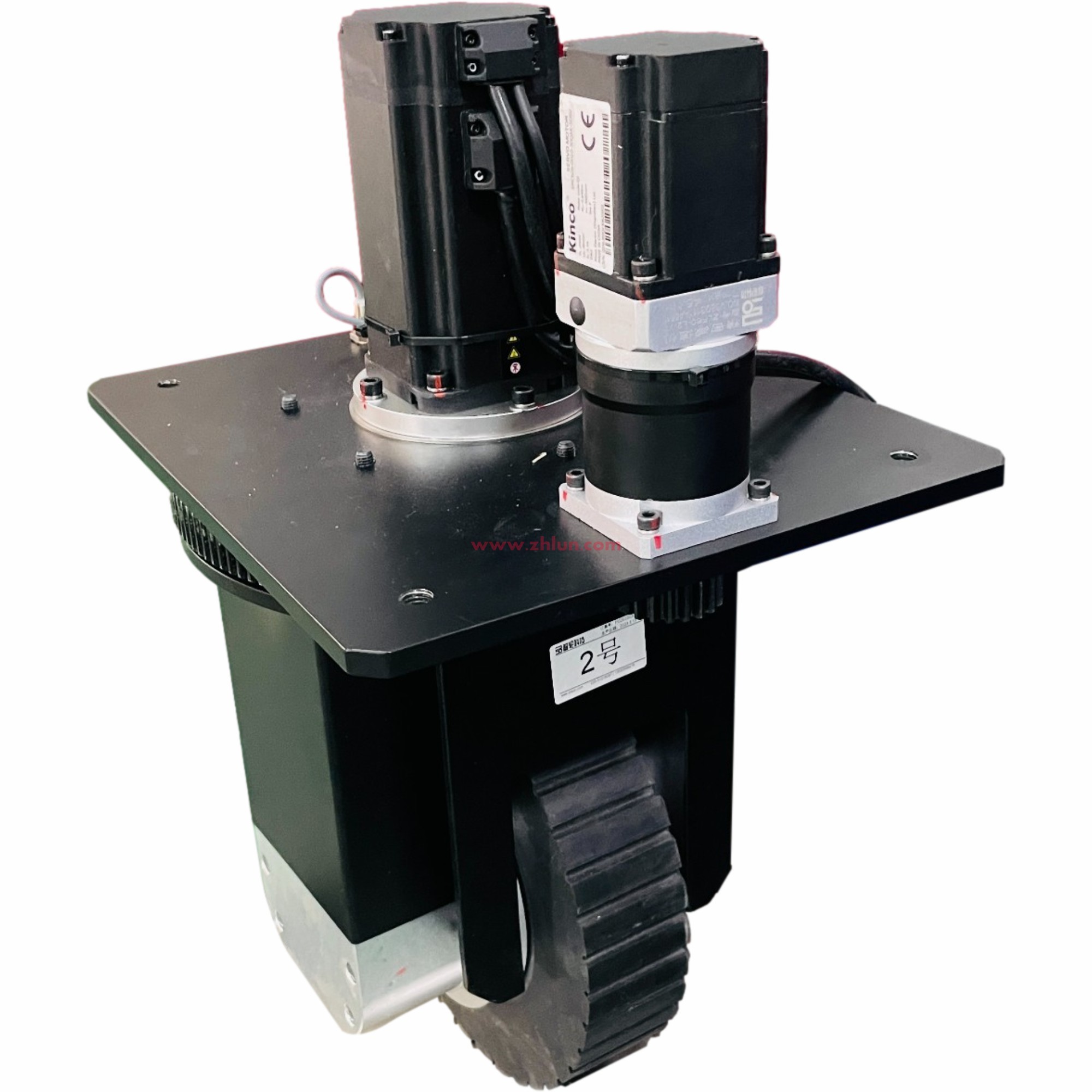

In the realm of automotive systems, **industrial drive wheels** serve as pivotal components that facilitate movement and enhance operational efficiency. These wheels are not merely circular objects; they are meticulously engineered elements that contribute significantly to the overall performance of vehicles. This article delves into how high-quality industrial drive wheels can drastically elevate the functionality and reliability of automotive systems.

The Importance of Quality in Drive Wheels

The performance of any vehicle largely hinges on the quality of its components. **High-quality drive wheels** ensure that vehicles operate smoothly under various conditions. Poorly manufactured wheels can lead to a myriad of issues, including uneven wear, decreased efficiency, and even safety hazards on the road. When we discuss quality in drive wheels, we refer to:

- **Durability**: The ability to withstand wear and tear over time.

- **Precision Engineering**: The manufacturing process that ensures the wheels fit perfectly and operate seamlessly.

- **Material Integrity**: Utilizing strong, resilient materials that can handle stress and environmental factors.

Types of Industrial Drive Wheels

Industrial drive wheels come in various types, each designed for specific applications. Understanding these types is crucial for selecting the right wheel for a given automotive system. Some notable types include:

Standard Drive Wheels

These wheels are designed for everyday automotive uses, providing a balance between performance and cost-effectiveness.

Heavy-Duty Drive Wheels

Intended for larger vehicles or those carrying heavy loads, heavy-duty wheels are constructed with robust materials to sustain significant weight and stress.

Specialized Drive Wheels

These wheels are tailored for unique environments, such as off-road conditions or extreme temperatures, ensuring optimal performance regardless of the challenges presented.

Materials Used in Drive Wheel Manufacturing

The quality and performance of industrial drive wheels are significantly influenced by the materials used in their production. Let's explore some commonly used materials:

Steel

Steel is favored for its strength and durability, making it suitable for heavy-duty applications. **Steel drive wheels** can endure substantial loads and resist deformation.

Aluminum

Aluminum wheels are lightweight and resistant to corrosion. They are ideal for applications where weight reduction is critical, enhancing fuel efficiency without compromising strength.

Polyurethane

Polyurethane wheels offer excellent traction and shock absorption, making them perfect for environments where noise reduction is essential. They are widely used in applications requiring smooth and quiet operation.

The Design Process of Industrial Drive Wheels

The design of drive wheels involves a comprehensive approach that combines engineering principles with real-world applications. Key considerations in the design process include:

Load Capacity

Engineers must calculate the expected loads the wheels will encounter to ensure they can support the vehicle's weight and any additional stresses.

Wheel Size and Geometry

The size and shape of the wheel play a significant role in its performance. A well-designed wheel geometry enhances stability and handling.

Surface Treatment

To improve durability, surface treatments such as coatings or heat treatments are often applied, which help protect the wheels from wear and environmental damage.

Performance Metrics of Drive Wheels

To assess the effectiveness of industrial drive wheels, several performance metrics should be considered:

Load-Bearing Capacity

This metric indicates how much weight a wheel can support before failing. A higher load-bearing capacity translates to greater durability and reliability.

Rolling Resistance

Low rolling resistance is crucial for efficient fuel consumption. Wheels with high rolling resistance can lead to increased energy expenditure, affecting overall vehicle performance.

Longevity

The lifespan of industrial drive wheels directly impacts operational costs. Quality wheels are designed to last longer, reducing the need for frequent replacements.

Maintenance of Drive Wheels for Optimal Performance

To ensure that industrial drive wheels perform at their best, regular maintenance practices are essential. Here are some best practices:

Regular Inspections

Conducting routine checks for signs of wear or damage can prevent unexpected failures and extend the wheel's lifespan.

Cleaning

Keeping wheels clean from debris and contaminants enhances their performance and prevents premature wear.

Proper Lubrication

Applying the correct lubricants to moving parts associated with the wheels ensures smooth operation and reduces friction.

Recent Innovations in Drive Wheel Technology

The field of industrial drive wheels is evolving, driven by technological advancements. Some recent innovations include:

Smart Wheels

Incorporating sensors into wheels can provide real-time data on performance metrics, allowing for proactive maintenance and enhanced operational efficiency.

Eco-Friendly Materials

The shift towards sustainable practices has led to the development of eco-friendly materials for manufacturing drive wheels, promoting environmental responsibility.

Enhanced Design Software

Advancements in design software allow engineers to simulate performance scenarios, resulting in better-designed wheels that meet specific needs and challenges.

Conclusion

In conclusion, the significance of quality industrial drive wheels in automotive systems cannot be overstated. They play a crucial role in enhancing performance, ensuring safety, and improving efficiency across various applications. By selecting the right type, material, and design, and by adhering to proper maintenance practices, vehicle operators can maximize the benefits offered by these vital components. As technology continues to evolve, staying informed about innovations in drive wheel design and materials will be essential for maintaining optimal performance in automotive systems.

FAQs

1. What are the main factors to consider when choosing industrial drive wheels?

When selecting industrial drive wheels, consider load capacity, material type, wheel size, and the specific application requirements.

2. How often should drive wheels be inspected?

Drive wheels should be inspected regularly, ideally every few months, or more frequently based on usage conditions.

3. Can drive wheels be repaired, or do they need to be replaced?

It depends on the extent of the damage. Minor issues may be repairable, while significant wear or structural damage often necessitates replacement.

4. Are there specific maintenance practices for different types of drive wheels?

Yes, maintenance practices may vary based on the material and design of the drive wheels. Always refer to manufacturer guidelines for best practices.

5. What are the advantages of using smart technology in drive wheels?

Smart technology in drive wheels provides real-time performance data, which helps in predictive maintenance and improves overall operational efficiency.

Related news

2025-06-13

How Quality Industrial Drive Wheels Enhance Performance in Automotive Systems

How Quality Industrial Drive Wheels Enhance Performance in Automotive Systems

Table of Contents

Introduction to Industrial Drive Wheels

The Importance of Quality in Drive Wheels

Types of Industrial Drive Wheels

Materials Used in Drive Wheel Manufacturing

The Design Process of Industrial Drive Wheels

Performance Metrics of Drive Wheels

Maintenance of Drive Wheels for Optimal Performa

2025-06-08

Maximizing Performance with the Best Motor Drive Wheels: A Comprehensive Guide

When it comes to improving vehicle performance, one of the most crucial components to consider is the motor drive wheel. The best motor drive wheels not only facilitate the movement of the vehicle but also significantly impact handling, stability, and overall efficiency. Understanding what makes a motor drive wheel stand out can help you make an informed decision, ensuring that your vehicle operat

2025-06-03

Transforming Your Drive: The Benefits of New AGV Wheels

Transforming Your Drive: The Benefits of New AGV Wheels

Table of Contents

Understanding AGV Wheels

The Importance of AGV Wheels in Automation

Key Advantages of New AGV Wheels

Enhanced Performance with Modern Wheels

Safety Implications of Upgrading AGV Wheels

Cost Efficiency and Reduced Maintenance

Choosing the Right AGV Wheels for Your Needs

Future Trends in AGV Wh

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 8, Longhe Westroad,

Longgui, Taihe Town, Guangzhou, Guangdong.China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License