News Categories

Transforming Your Drive: The Benefits of New AGV Wheels

Release time:

2025-06-03

Transforming Your Drive: The Benefits of New AGV Wheels

Table of Contents

- Understanding AGV Wheels

- The Importance of AGV Wheels in Automation

- Key Advantages of New AGV Wheels

- Enhanced Performance with Modern Wheels

- Safety Implications of Upgrading AGV Wheels

- Cost Efficiency and Reduced Maintenance

- Choosing the Right AGV Wheels for Your Needs

- Future Trends in AGV Wheel Technology

- FAQs About AGV Wheels

Understanding AGV Wheels

Automated Guided Vehicles (AGVs) are pivotal in modern warehouse and manufacturing environments. Designed to transport materials across facilities with minimal human intervention, AGVs rely heavily on their wheel systems. **AGV wheels** come in various materials, sizes, and designs, each tailored to specific operational demands. Understanding these wheels' mechanics and functionalities is essential for maximizing the efficiency and safety of any automated system.

The Importance of AGV Wheels in Automation

As the backbone of **automated transportation**, AGV wheels significantly influence the overall performance of AGVs. These wheels not only determine the vehicle's ability to move but also affect its steering capabilities, stability, and load capacity. Any enhancement in wheel design can lead to improved functionality, reliability, and ultimately, productivity.

Types of AGV Wheels

AGV wheels generally fall into several categories:

- **Polyurethane Wheels**: Known for their durability and high traction, these wheels are ideal for smooth surfaces.

- **Rubber Wheels**: Best suited for environments where noise reduction is essential, rubber wheels provide excellent shock absorption.

- **Metal Wheels**: These are often used in heavy-duty applications due to their robustness and longevity.

Choosing the right type of wheel is vital for optimizing the operational efficiency of AGVs.

Key Advantages of New AGV Wheels

Investing in new AGV wheels offers a multitude of advantages that can substantially enhance your operational efficiency.

1. Improved Load Capacity

New wheel technologies are designed to handle heavier loads without compromising performance. This improvement means your AGVs can transport more materials in a single trip, significantly increasing throughput.

2. Enhanced Maneuverability

Modern AGV wheels are engineered to provide better grip and traction, allowing for smoother navigation even in tight spaces. Enhanced maneuverability translates to reduced downtime and quicker operational cycles.

3. Increased Speed and Efficiency

Upgrading wheels can enable AGVs to reach higher speeds while maintaining stability. Increased speed not only boosts productivity but also allows for quicker cycle times, which is critical in fast-paced environments.

Enhanced Performance with Modern Wheels

The performance of AGVs is significantly influenced by the wheels they utilize. New technologies, such as smart wheels equipped with sensors, enable real-time data collection and analysis, allowing operators to monitor performance metrics effectively.

1. Smart Wheel Technology

Smart wheels allow for predictive maintenance, reducing unexpected breakdowns and enhancing overall system reliability. By monitoring conditions such as wear and tear, these wheels enable proactive maintenance schedules, leading to longer lifespans and decreased operational costs.

2. Noise Reduction

As businesses become increasingly aware of their environmental impacts, noise reduction has become a priority. New AGV wheels use advanced materials to minimize sound, resulting in quieter operations—a benefit for both staff and surrounding environments.

Safety Implications of Upgrading AGV Wheels

Safety is paramount in any industrial setting. Upgrading to new AGV wheels can significantly enhance safety protocols.

1. Improved Stability

New wheel designs often feature enhanced stability mechanisms that reduce the risk of tipping or collisions. This stability is vital in preventing accidents and ensuring the safety of personnel in the vicinity.

2. Better Traction

Enhanced traction from modern AGV wheels means that vehicles are less likely to slip, especially in environments with variable floor conditions. This reliability is crucial for maintaining safe operations in any setting.

Cost Efficiency and Reduced Maintenance

One of the most powerful arguments for upgrading AGV wheels is the potential for cost savings.

1. Lower Operational Costs

Although the initial investment in new wheels may seem high, the long-term savings associated with increased efficiency and reduced downtime often outweighs these costs. Improved load capacity and speed can lead to significant operational savings.

2. Reduced Maintenance Frequency

New wheel technologies require less frequent maintenance, translating to lower labor costs and reduced downtime. With fewer repairs needed, organizations can allocate resources more effectively.

Choosing the Right AGV Wheels for Your Needs

Selecting the correct AGV wheels involves understanding your specific operational requirements.

1. Assessing Surface Conditions

Different surfaces require different wheels. For instance, rough or uneven surfaces may demand wheels with better shock absorption and durability.

2. Weight Considerations

Evaluating the load that your AGVs will carry is crucial. Ensure that the wheels you choose can handle the maximum expected weight without compromising performance.

3. Environmental Factors

Consider the environment where your AGVs will operate. Factors such as temperature, humidity, and exposure to chemicals can influence wheel material selection.

Future Trends in AGV Wheel Technology

As technology evolves, so too does the design and functionality of AGV wheels.

1. Eco-Friendly Materials

The demand for sustainable practices is influencing the materials used in wheel production. Future AGV wheels may feature biodegradable components or be composed of recycled materials.

2. Integration with IoT

As the Internet of Things (IoT) continues to penetrate industrial applications, AGV wheels may incorporate IoT technology for enhanced data analysis and predictive maintenance capabilities.

FAQs About AGV Wheels

1. What are AGV wheels made of?

AGV wheels can be made from various materials, including polyurethane, rubber, and metal, each suited for different applications.

2. How often should AGV wheels be replaced?

The replacement frequency depends on the wheel material, the load they handle, and operational conditions. Regular inspections can help determine when replacement is necessary.

3. Can I retrofit my existing AGVs with new wheels?

In many cases, existing AGVs can be retrofitted with new wheels, but it's crucial to ensure compatibility with the AGV's design.

4. What factors influence AGV wheel performance?

Performance can be influenced by wheel material, design, load capacity, and environmental conditions.

5. Are smart AGV wheels worth the investment?

Smart AGV wheels can provide significant long-term benefits through predictive maintenance and enhanced operational efficiency, making them a worthwhile investment.

Conclusion

Upgrading to new AGV wheels is not merely a maintenance task; it is a strategic move that can transform your operations. From improved load capacity to enhanced safety features, the benefits are manifold. As the industry evolves, staying ahead with modern wheel technology can lead to increased productivity and reduced operational costs. Investing in advanced AGV wheels today ensures that your operations are not only efficient but also positioned for future growth. Embrace the change, and let new AGV wheels take your automated systems to new heights.

Related news

2025-06-03

Transforming Your Drive: The Benefits of New AGV Wheels

Transforming Your Drive: The Benefits of New AGV Wheels

Table of Contents

Understanding AGV Wheels

The Importance of AGV Wheels in Automation

Key Advantages of New AGV Wheels

Enhanced Performance with Modern Wheels

Safety Implications of Upgrading AGV Wheels

Cost Efficiency and Reduced Maintenance

Choosing the Right AGV Wheels for Your Needs

Future Trends in AGV Wh

2025-05-29

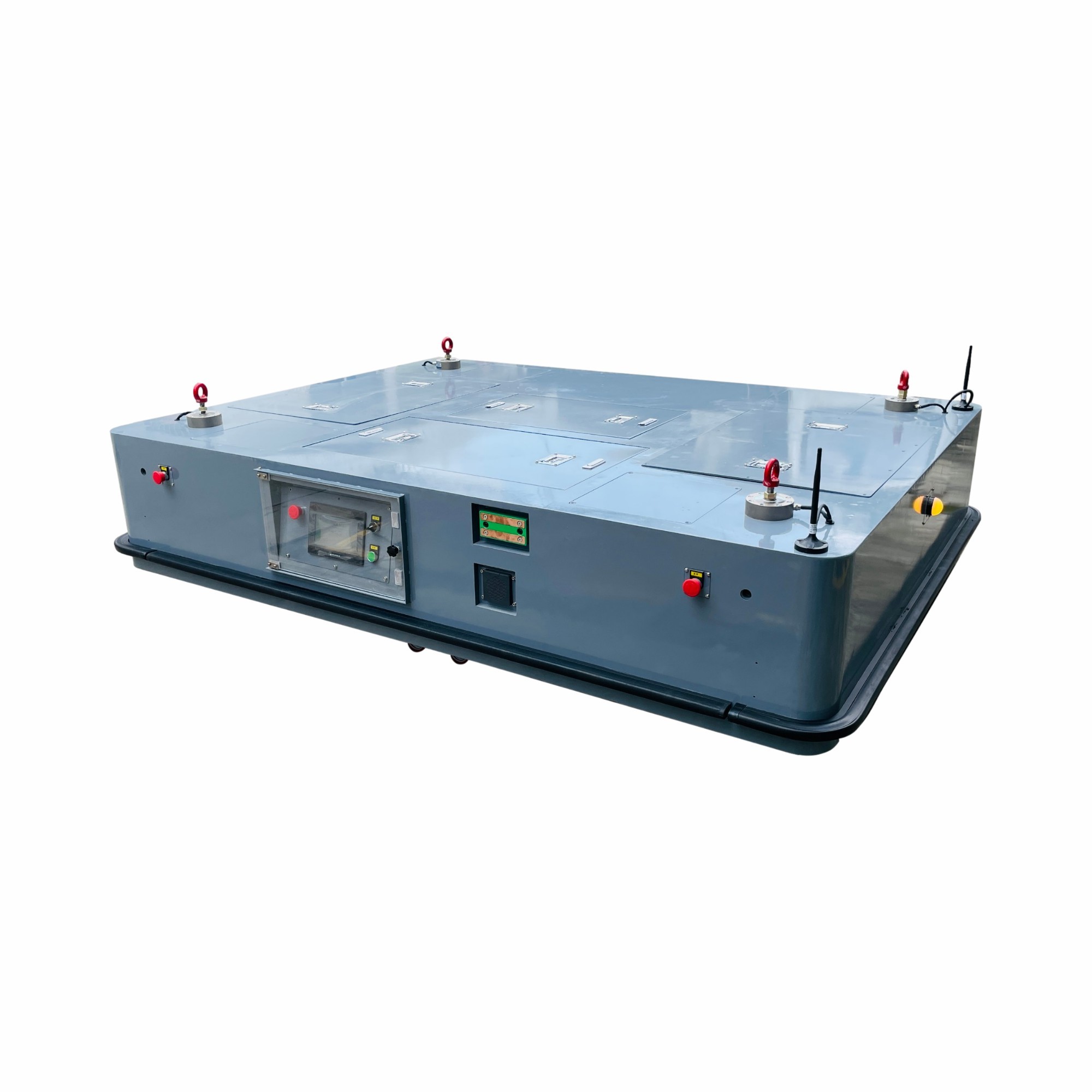

Exploring Durable AGV Platforms: The Future of Logistics and Warehousing

As industries strive to enhance efficiency and reduce operational costs, the implementation of Autonomous Guided Vehicles (AGVs) has become increasingly prevalent. Durable AGV platforms serve as the backbone of modern logistics, designed to streamline the movement of goods within warehouses and distribution centers.

One of the primary advantages of durable AGV platforms is their resilience. Built

2025-05-26

New AGV Platforms represent the latest innovation in automated guided vehicle technology, designed to revolutionize material handling and logistics across various industries. These advanced platforms offer enhanced precision, flexibility, and efficiency, making them indispensable tools for modern warehouses, manufacturing plants, and distribution centers. The New AGV Platforms are engineered to navigate complex environments autonomously, providing reliable transport of goods without the need for manual intervention.

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 8, Longhe Westroad,

Longgui, Taihe Town, Guangzhou, Guangdong.China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License