编号 :

Revolutionizing Industrial Logistics: The Complete Guide to Underride Lift-Type Pallet Handling AGVs

Product number:

隐藏域元素占位

- Product description

-

Revolutionizing Industrial Logistics: The Complete Guide to Underride Lift-Type Pallet Handling AGVs

Introduction to Next-Generation Material Handling Solutions

In the era of Industry 4.0, underride lift-type pallet handling AGVs represent a transformative advancement in automated material transportation. These innovative automated guided vehicles are redefining efficiency standards in industrial logistics by combining autonomous navigation with sophisticated lifting operation principles. Designed to perform seamlessly beneath loads and transport them with precision, these AGVs offer unparalleled flexibility in modern manufacturing and warehouse environments.Technical Specifications and Engineering Excellence

Our underride lift-type AGV showcases exceptional engineering capabilities:Load Capacity and Performance

Customizable payload options from 500kg to 80tons

Adjustable lifting heights ranging from 100mm to 300mm

Precision lifting operation with ±10mm positioning accuracy

Variable speed settings from 0.5m/s to 1.5m/s

Control Systems and Navigation

Multi-sensor fusion navigation combining laser guidance with visual recognition

Dual-mode operation: fully autonomous and manual remote control

Real-time path optimization algorithms

Cloud-based fleet management compatibility

Power and Endurance

High-capacity lithium-ion battery systems

8-10 hours continuous operation per charge

Automatic charging capability with opportunity charging support

Energy recovery during braking and descent

Advanced Features and Customization Options

Intelligent Operation CapabilitiesAutomatic load dimension detection

Pallet recognition and verification systems

Adaptive lifting force control based on load weight

Self-diagnostic and predictive maintenance features

Safety and Reliability

360° obstacle detection using LiDAR and ultrasonic sensors

Emergency stop systems with multiple redundancy

Load stability monitoring during transportation

Anti-collision and personnel protection systems

Customization Flexibility

Tailored dimensions for specific aisle widths

Custom paint colors and corporate branding

Specialized attachment interfaces

Integration with existing warehouse management systems

Industry Applications and Implementation Scenarios

Warehousing and Distribution

Automated pallet put-away and retrieval

Cross-docking operations

Inventory rotation and reorganization

Loading and unloading of transportation vehicle

Manufacturing Sector

Just-in-time material delivery to production lines

Raw material transportation between storage and processing areas

Finished product movement to shipping docks

Tooling and equipment relocation

Specialized Environments

Cold storage facilities (-30°C to +40°C operation)

Clean room manufacturing

Hazardous material handling

Market Insights and Industry Trends

Global AGV Market Overview

The worldwide AGV market is experiencing unprecedented growth, driven by:Increasing labor costs and workforce availability challenges

Rising demand for operational efficiency

Growing adoption of Industry 4.0 technologies

Expansion of e-commerce and logistics sectors

Technology Development Trends

Integration of artificial intelligence and machine learning

Advancements in sensor technology and data processing

Future Outlook

Expected CAGR of 12.3% in the material handling AGV sector

Growing demand for customized solutions

Expansion into new application areas

Implementation Benefits and Return on Investment

Operational Advantages

30-50% reduction in material handling costs

24/7 operation capability without fatigue

Improved inventory accuracy through automated tracking

Enhanced workplace safety

Financial Considerations

Typical ROI period of 12-18 months

Reduced product damage through precise handling

Lower energy consumption compared to traditional equipment

Minimal maintenance requirements

Industry Trends and Development Prospects

The global AGV market is experiencing robust growth, driven by the escalating adoption of automation in logistics and manufacturing. Key trends shaping the industry include:Labor Optimization: Growing reliance on automated solutions to address labor shortages and reduce operational costs.

Technological Advancements: Innovations in artificial intelligence, machine learning, and sensor technology are enhancing AGV capabilities, enabling greater autonomy and efficiency.

Sustainability Goals: AGVs contribute to greener operations by optimizing energy use and reducing waste.

The future development of automated guided vehicle technology will likely focus on enhancing interoperability with other automated services, improving energy efficiency, and expanding its application across more industries.

Why Choose This AGV?

Tailored Solutions: Customizable features ensure the AGV aligns with specific operational needs.

Reliability: Robust design and proven performance in demanding environments.

Support Services: Comprehensive technical support and maintenance programs

Related products

undefined

Products Message

Products

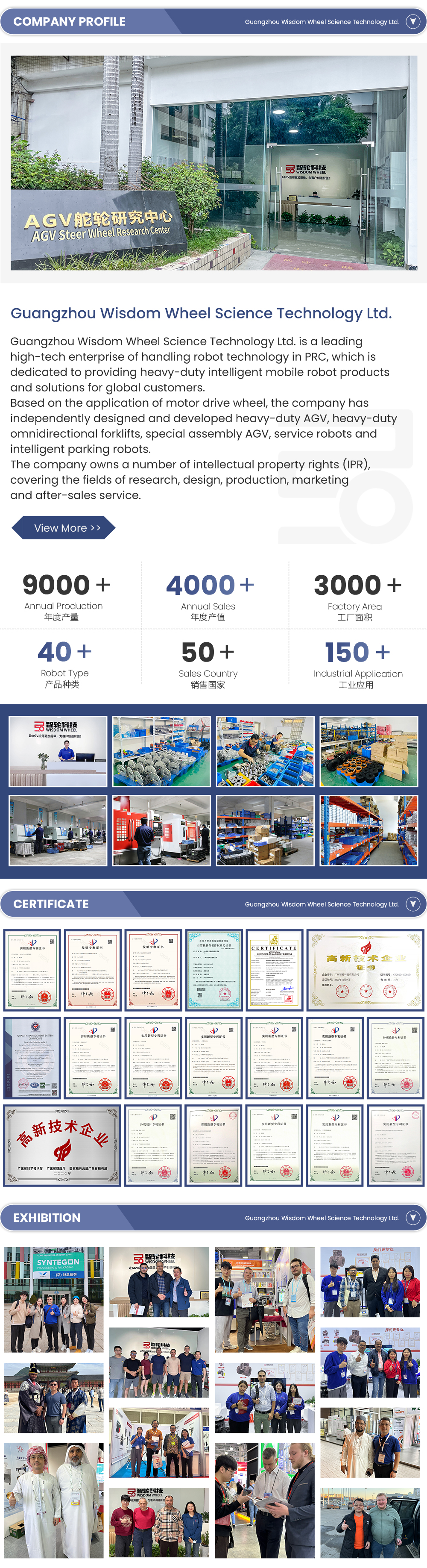

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct