编号 :

ZL-Lifting Mold Change and Handling AGV

Product number:

隐藏域元素占位

- Product description

-

Revolutionizing Industrial Material Handling: The Advanced Die-Lifting and Transfer AGV with Hydraulic Automation

Executive Summary

In today's rapidly evolving industrial landscape, the integration of specialized automated guided vehicles (AGVs) has become paramount for enhancing operational efficiency and maintaining competitive advantage. Our cutting-edge die-lifting and transfer AGV with hydraulic automation system represents the pinnacle of industrial innovation, engineered to transform mold and heavy payload handling operations across various sectors. This comprehensive solution addresses the growing need for flexible, reliable, and efficient material transportation in modern manufacturing environments.Technical Specifications and Customization Capabilities

Our hydraulic die-handling AGV boasts an impressive array of technical features designed to meet the most demanding industrial requirements:- Lifting Capacity: Custom-engineered solutions ranging from 2 to 30 tons, with specialized configurations available for exceptional weight requirements

- Hydraulic System: A precision-engineered lifting and lowering structure ensures stable and controllable vertical movement with millimeter-level accuracy.

- Navigation System: Advanced laser guidance technology complemented by inertial navigation for uninterrupted operation in challenging environments

- Control Interface: Dual-mode operation featuring wireless remote control and integrated central management system compatibility

- Power Management: High-capacity lithium-ion battery system with opportunity charging capability for continuous operation

- Safety Systems: Comprehensive protection package including 360° obstacle detection, automatic emergency braking, and load monitoring sensor

Industry 4.0 Integration and Operational Excellence

This AGV solution embodies the principles of the Fourth Industrial Revolution, featuring:- IoT Connectivity: Real-time data transfer for performance monitoring and predictive maintenance

- Cloud Integration: Enabling Remote Management and Operational Profiling via Secure Cloud Platforms

- Interoperability: Seamless integration with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) systems

- Adaptive Intelligence: Machine learning algorithms that optimize routing and operational efficiency based on historical data

Applications Across Industries

Automotive Manufacturing- Automated die changes in stamping presses

- Just-in-sequence component delivery to assembly lines

- Tooling transportation between production cells

Heavy Equipment and Machinery

- Large component handling in assembly operation

- Maintenance part logistics in large-scale facilitie

- Mold transportation in foundry application

Consumer Goods Manufacturing

- High-capacity material handling in appliance production

- Packaging line feeding and optimization

- Warehouse automation and storage retrieval

Aerospace and Defense

- Precision component transportation

- Tooling handling in composite manufacturing

- Assembly line support operations

Future Development Prospects

The future of die-handling AGV technology is poised for significant advancements:- Artificial Intelligence Integration: Enhanced decision-making capabilities and autonomous operation

- 5G Connectivity: Ultra-reliable low-latency communication for real-time control

- Advanced Materials: Lightweight composite structures for improved energy efficiency

- Sustainable Solutions: Development of eco-friendly power systems and energy recovery technologies

Competitive Advantages

Our die-lifting AGV solution offers distinct advantages in the marketplace:- Proven Reliability: Extensive testing and validation in real-world industrial environments

- Technical Support: Comprehensive after-sales service and maintenance programs

- Customization Expertise: Deep engineering capability to address unique application challenges

- Future-Proof Design: Modular architecture allowing for technology upgrades and expansion

Implementation and ROI Considerations

Companies implementing our AGV solution can expect:- Rapid ROI: Typically achieved within 12-24 months through labor reduction and efficiency gains

- Operational Flexibility: Ability to adapt to changing production requirements

- Quality Improvement: Reduced product damage through precise handling

- Safety Enhancement: Elimination of manual heavy lifting operations

Why Choose Our Solution?

- Complete customization options for specific application needs

- Proven reliability in demanding industrial environments

- Advanced safety features ensuring workplace security

- Reduced operational costs through automation

- Technical support and maintenance services

Related products

undefined

Products Message

Products

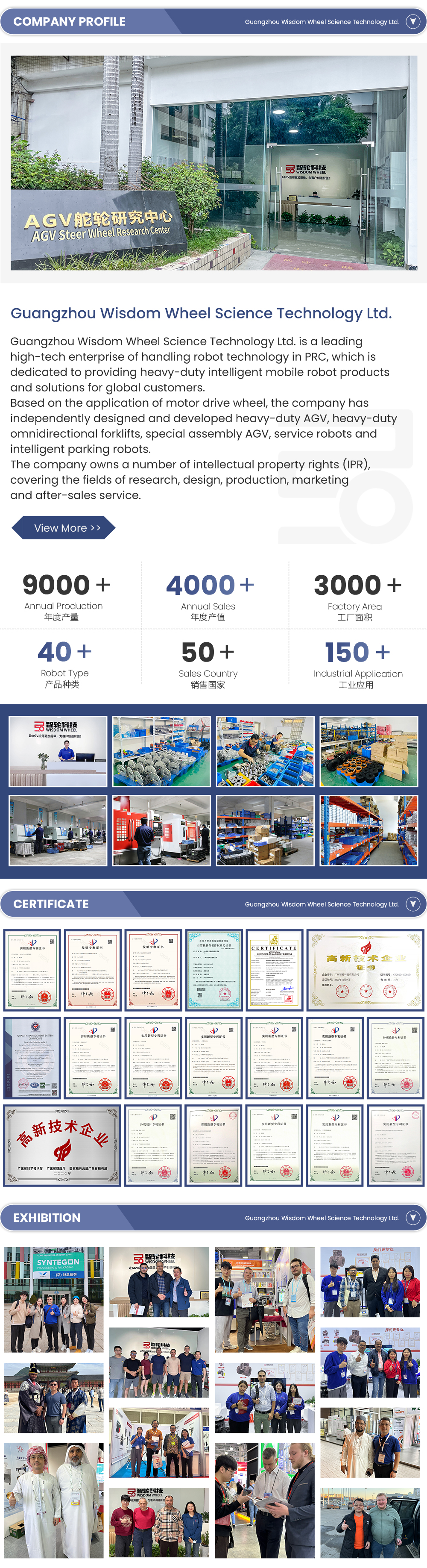

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct