How New AGV Wheels Enhance Efficiency in Automotive Systems

Release time:

2025-06-23

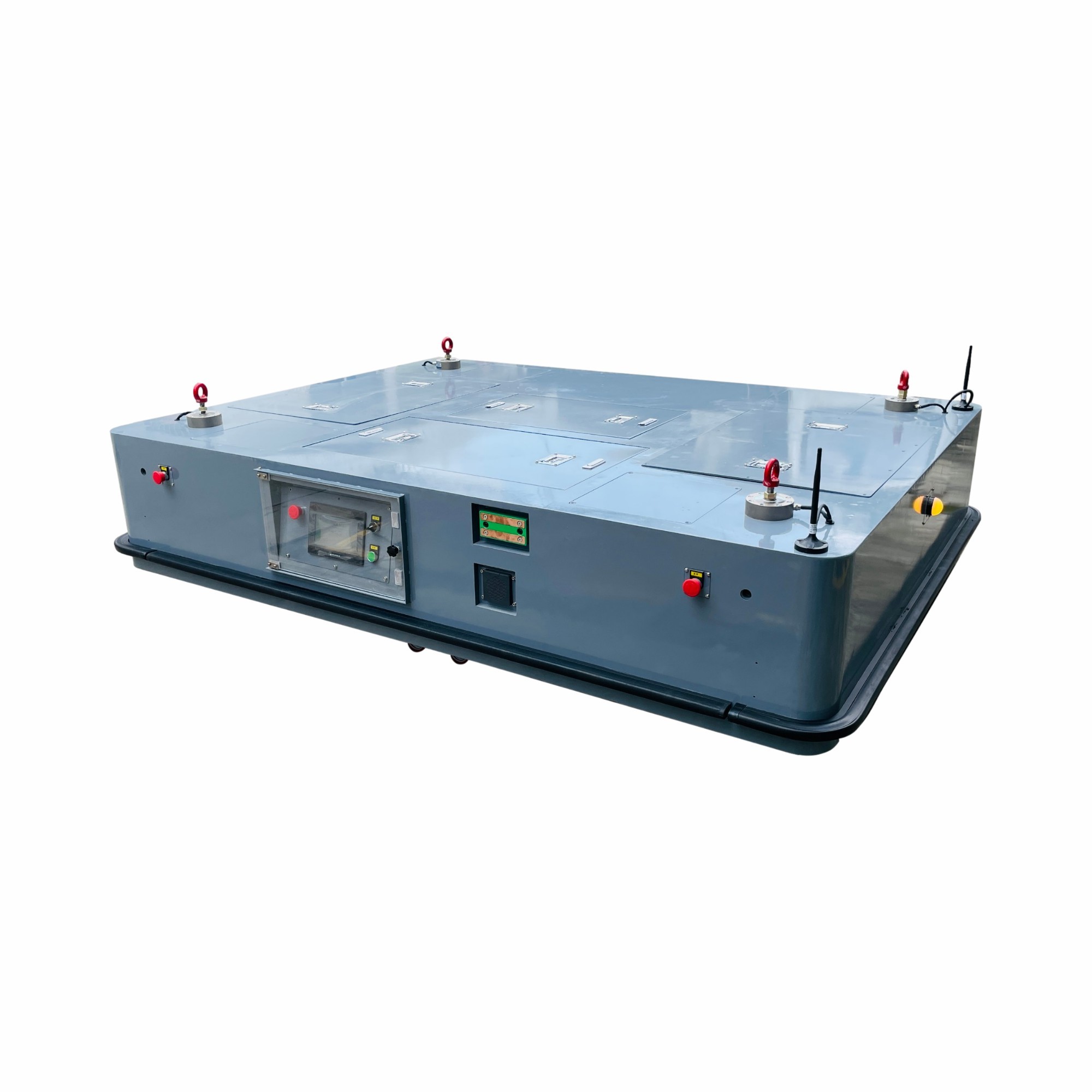

In the fast-paced automotive industry, efficiency is paramount. Automated Guided Vehicles (AGVs) have emerged as a game-changing solution, streamlining processes and enhancing productivity. At the core of AGV technology are the **wheels** that facilitate movement. Recent innovations in AGV wheel design have made them more efficient, durable, and adaptable to various operational environments. This article explores how these new AGV wheels are revolutionizing automotive systems by improving efficiency.

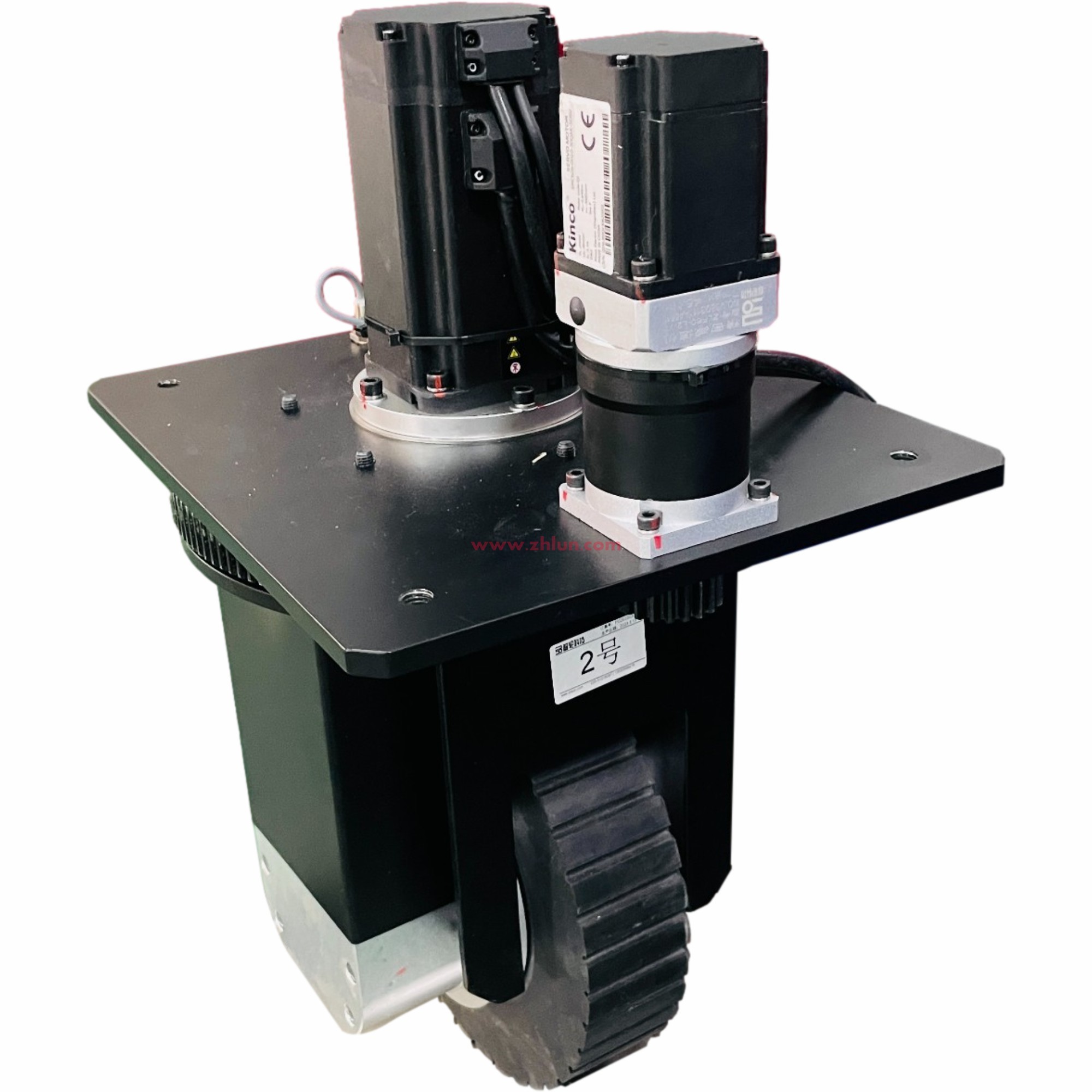

Integrating sensors within AGV wheels enables real-time monitoring of performance metrics such as speed, load weight, and wear. This data is invaluable for predictive maintenance and operational optimization.

Recent innovations in tread design have significantly improved traction. This enhancement minimizes the risk of slipping, especially in dynamic environments such as automotive assembly lines.

New materials and designs focus on reducing noise pollution, creating a quieter working environment. This is particularly important in facilities where human workers and AGVs coexist.

With superior design and enhanced capabilities, new AGV wheels reduce downtime and increase the efficiency of material handling processes, allowing manufacturers to produce more in less time.

Investing in high-quality AGV wheels translates to long-term cost savings. Reduced maintenance costs, decreased wear and tear, and enhanced reliability lead to lower operational expenses.

New AGV wheels are designed with safety in mind, minimizing the risk of accidents and injuries in the workplace. This is achieved through features like anti-slip designs and real-time monitoring systems that alert operators to potential hazards.

In automotive manufacturing, AGVs equipped with the latest wheel technologies can efficiently transport parts and materials throughout the production line, ensuring seamless workflow and reducing bottlenecks.

New AGV wheel technologies are versatile enough to adapt to different surfaces and conditions, ensuring consistent performance whether in a manufacturing plant, warehouse, or assembly line.

A major automotive manufacturer implemented advanced AGV wheels in its assembly line, resulting in a 30% increase in production speed and a 20% reduction in operational costs. The smart wheel technology enabled real-time monitoring, allowing for immediate adjustments and minimizing downtime.

In a large automotive parts warehouse, the introduction of new AGV wheels led to a 40% improvement in inventory management. The enhanced traction and stability of the wheels enabled AGVs to navigate challenging layouts, ensuring timely delivery of parts to assembly lines.

The introduction of new AGV wheels has significantly enhanced efficiency in automotive systems. With their advanced materials, smart technologies, and design innovations, these wheels are transforming how automotive manufacturers operate. As we look to the future, the continued evolution of AGV wheel technology will undoubtedly play a pivotal role in driving efficiency, productivity, and safety in the automotive industry.

Related news

2025-06-23

How New AGV Wheels Enhance Efficiency in Automotive Systems

2025-06-18

Exploring the Benefits of Durable AGV Platforms in Logistics and Warehousing

2025-06-13

How Quality Industrial Drive Wheels Enhance Performance in Automotive Systems

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 8, Longhe Westroad,

Longgui, Taihe Town, Guangzhou, Guangdong.China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct