Quality Industrial Drive Wheels: A Comprehensive Comparison of Materials and Designs

Release time:

2026-01-29

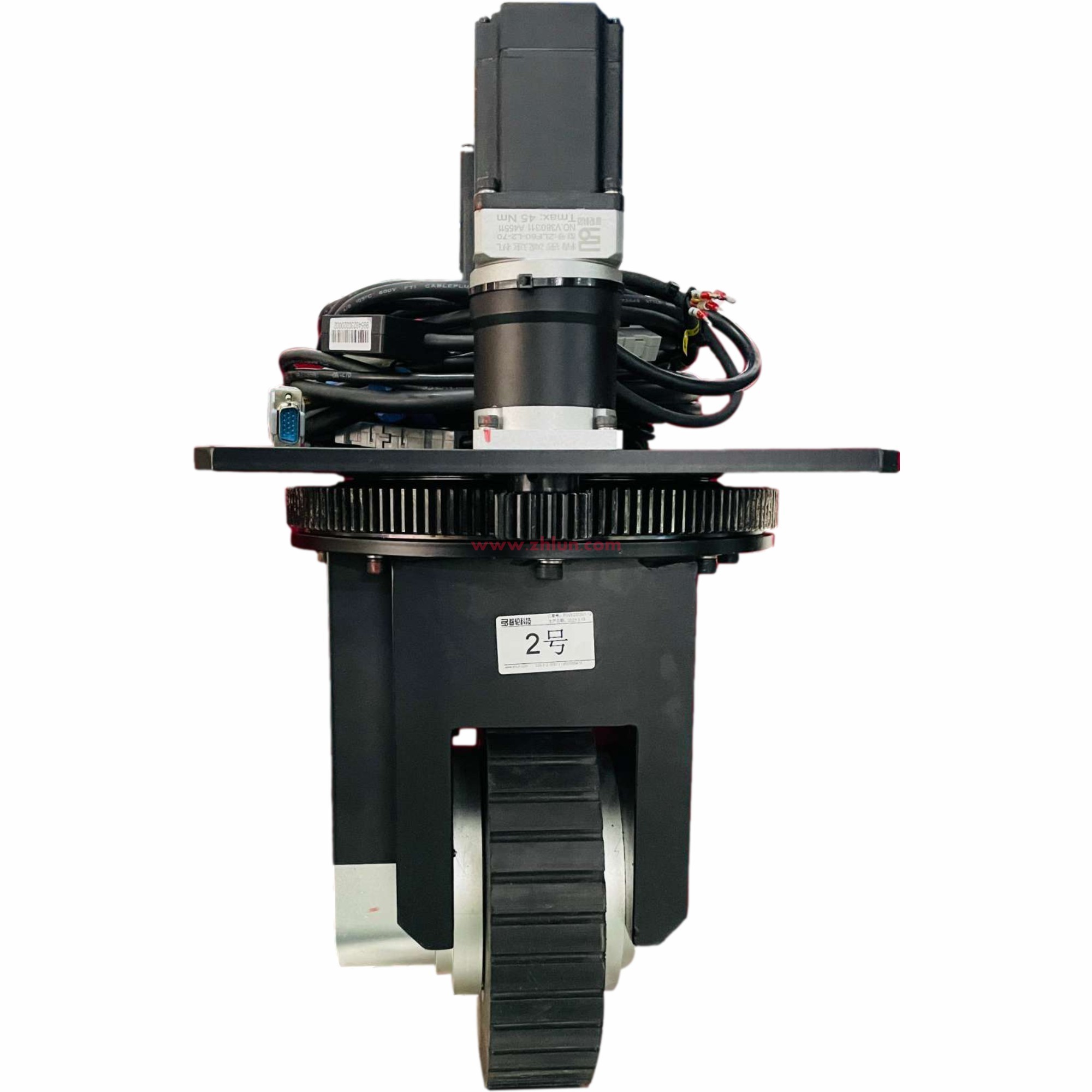

Understanding Quality Industrial Drive Wheels: A Detailed Analysis

The Importance of Drive Wheels in Industrial Applications

In the vast landscape of industrial machinery, **drive wheels** serve as a crucial component. They are responsible for transferring power and motion, enabling machinery to function efficiently. Selecting the right type of drive wheel can significantly enhance productivity, reduce operational costs, and prolong the lifespan of equipment.

Types of Drive Wheels: An Overview

Drive wheels come in various types, each designed for specific applications. The most common categories include:

1. Solid Drive Wheels

Solid drive wheels are made from a single piece of material, offering durability and stability. They are suitable for heavy loads and rough terrains, making them ideal for industrial settings.

2. Pneumatic Drive Wheels

These wheels are air-filled and provide excellent shock absorption. They are perfect for applications requiring mobility over uneven surfaces but may lack the load-bearing capacity of solid wheels.

3. Polyurethane Drive Wheels

Known for their versatility, polyurethane wheels are resistant to abrasion and chemical damage. They offer a balance between durability and performance, making them suitable for various applications.

4. Rubber Drive Wheels

Rubber wheels are renowned for their noise-reducing properties and excellent grip. They are preferred in environments where smooth operation is critical, such as warehouses and retail spaces.

Material Comparison: Choosing the Right Drive Wheel

Selecting the appropriate material for drive wheels is essential for ensuring operational efficiency. Let’s delve into the most commonly used materials and their characteristics.

1. Steel Drive Wheels

Steel wheels are sturdy and can withstand heavy loads. They are often used in heavy machinery and warehouse equipment. However, they can be prone to rust and corrosion, requiring protective coatings.

Advantages

- High load-bearing capacity

- Exceptional durability

- Suitable for harsh environments

Disadvantages

- Heavier than other options

- Prone to corrosion without treatment

2. Aluminum Drive Wheels

Aluminum wheels are lightweight and resistant to corrosion. They offer a balance of strength and weight, making them suitable for various applications, particularly in conveyor systems.

Advantages

- Lightweight design

- Corrosion-resistant

- Good for applications requiring speed

Disadvantages

- May not bear as much load as steel

- More expensive than steel options

3. Polyurethane Drive Wheels

Polyurethane wheels offer a blend of durability and elasticity. They can handle various surfaces and conditions, making them a popular choice in many industries.

Advantages

- Resistant to wear and tear

- Good shock absorption

- Versatile for different applications

Disadvantages

- Can be more expensive than rubber wheels

- May degrade in extreme temperatures

4. Rubber Drive Wheels

Rubber wheels provide excellent traction and shock absorption. They are commonly used in applications requiring quiet operation and good grip.

Advantages

- Noise reduction

- Excellent grip on various surfaces

- Suitable for indoor applications

Disadvantages

- Less durable than steel or aluminum

- Can wear out faster on rough surfaces

Design Considerations for Industrial Drive Wheels

Beyond material selection, the design of industrial drive wheels plays a pivotal role in their effectiveness. Consider the following factors when selecting drive wheels for your operation:

1. Wheel Diameter

The diameter of a drive wheel affects its performance. Larger wheels can navigate uneven surfaces more effectively, while smaller wheels tend to offer better maneuverability.

2. Tread Pattern

The tread pattern on a drive wheel impacts traction. Specific patterns are designed for different surfaces, making it crucial to consider the environment in which the wheels will be used.

3. Load Capacity

Understanding the load capacity of your chosen drive wheel is essential. Ensure that the wheel can support the weight of the machinery and any additional loads without compromising performance.

4. Axle Compatibility

Drive wheels must be compatible with the axle system of your machinery. Ensure a proper fit to maintain optimal functionality and safety.

Applications of Industrial Drive Wheels

Different industries utilize drive wheels in various applications. Here are some prominent examples:

1. Manufacturing

In manufacturing environments, drive wheels are essential for conveyor systems and machinery that require efficient movement of materials.

2. Warehousing

Drive wheels play a critical role in forklifts and pallet jacks, enabling the effective transportation of goods within storage facilities.

3. Food and Beverage

In the food and beverage industry, drive wheels made from non-toxic materials are necessary for ensuring hygiene and compliance with safety regulations.

4. Agriculture

Agricultural machinery often employs robust drive wheels to navigate uneven terrains, ensuring operations run smoothly.

How to Maintain Industrial Drive Wheels

Regular maintenance of drive wheels can significantly enhance their lifespan and performance. Consider the following maintenance tips:

1. Regular Inspections

Conduct frequent inspections for wear and tear, ensuring wheels are free from debris and damage. This proactive approach can prevent costly downtimes.

2. Cleaning

Maintain cleanliness by removing grime and dirt that can affect wheel performance and longevity.

3. Lubrication

For wheels with moving parts, ensure proper lubrication to facilitate smooth operation and reduce friction.

Choosing the Right Supplier for Industrial Drive Wheels

Selecting a reliable supplier is as important as choosing the right wheels. Consider the following factors when making your selection:

1. Product Range

A supplier with a diverse product range can offer customized solutions tailored to your specific needs.

2. Quality Assurance

Ensure the supplier adheres to strict quality control measures to guarantee that you receive durable and high-quality products.

3. Customer Support

Choose a supplier that offers robust customer support to assist you with any inquiries or issues that may arise after your purchase.

Frequently Asked Questions (FAQs)

1. What factors should I consider when choosing industrial drive wheels?

Consider materials, load capacity, tread patterns, and the specific application needs to select the most suitable drive wheels.

2. How do I determine if my drive wheels need replacing?

Look for visible signs of wear, reduced performance, or any unusual noises indicating that the wheels may need replacement.

3. Are polyurethane drive wheels suitable for outdoor use?

Yes, polyurethane wheels can be used outdoors, but their performance may vary based on environmental conditions.

4. What is the typical lifespan of industrial drive wheels?

The lifespan can vary significantly based on materials, usage, and maintenance, generally ranging from several months to a few years.

5. How can I improve the performance of my drive wheels?

Regular maintenance, selecting the right material and design, and ensuring proper load distribution can enhance performance.

Conclusion

Selecting the right industrial drive wheels is a critical decision that impacts operational efficiency and equipment longevity. By understanding the various materials and designs available, we can make informed choices tailored to our specific applications. Regular maintenance and choosing a reputable supplier further enhance the effectiveness of these essential components. As industries continue to evolve, staying informed will ensure that we remain ahead of the curve in optimizing our machinery's performance.

Related news

2026-02-03

Exploring the Advantages of Durable AGV Platforms in Logistics and Warehousing

2026-01-29

Quality Industrial Drive Wheels: A Comprehensive Comparison of Materials and Designs

2026-01-23

Unlocking the Potential: A Comprehensive Guide to the Best Motor Drive Wheels

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct