News Categories

A Comprehensive Guide to Extending the Lifespan of Industrial Drive Wheels

Release time:

2026-01-08

A Comprehensive Guide to Extending the Lifespan of Industrial Drive Wheels

Table of Contents

- 1. Introduction to Industrial Drive Wheels

- 2. The Importance of Quality Drive Wheels

- 3. Types of Industrial Drive Wheels

- 4. Essential Maintenance Practices for Drive Wheels

- 5. Regular Inspections: A Key to Longevity

- 6. Choosing the Right Material for Drive Wheels

- 7. Environmental Factors Affecting Drive Wheel Durability

- 8. Troubleshooting Common Drive Wheel Issues

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Industrial Drive Wheels

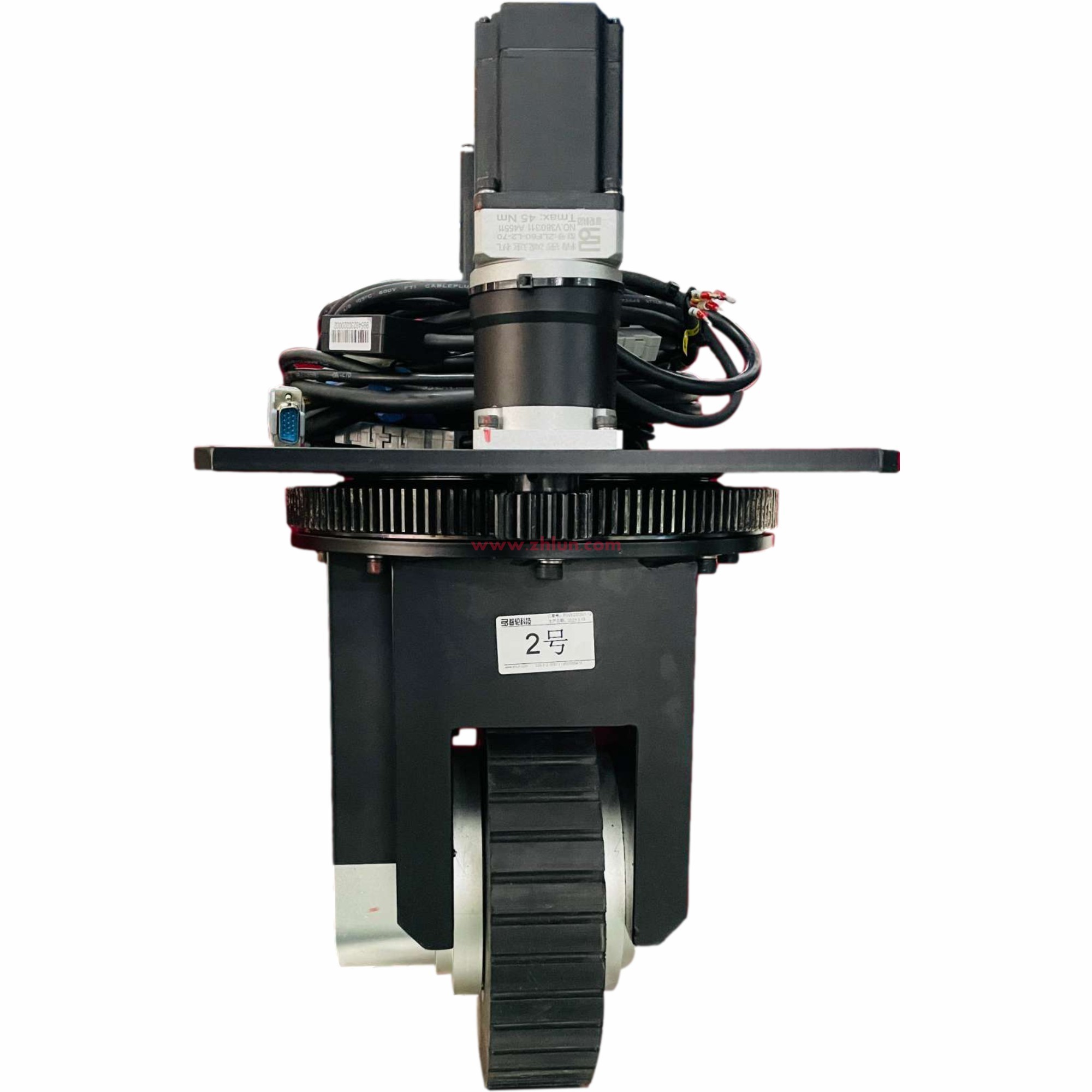

Industrial drive wheels are crucial components in various machinery and transportation systems. They play a pivotal role in transferring motion and ensuring efficient operation across industries. Understanding how to maintain these wheels can greatly enhance their lifespan and efficiency, making it essential for businesses to invest time and resources into proper care.

2. The Importance of Quality Drive Wheels

Quality drive wheels contribute significantly to the overall performance of machines. Beyond just functionality, they impact safety, energy efficiency, and productivity. High-quality wheels minimize wear and tear, leading to reduced downtime and maintenance costs.

Enhanced Safety

In sectors where heavy machinery operates, the integrity of drive wheels is paramount. Defective wheels can lead to accidents, posing risks to workers and equipment alike.

Cost-Effectiveness

Investing in quality drive wheels may seem costly upfront but can lead to significant savings over time due to decreased maintenance needs and longer replacement cycles.

3. Types of Industrial Drive Wheels

Understanding the various types of industrial drive wheels available helps businesses select the right ones for their specific needs.

Polyurethane Wheels

These wheels are known for their durability and versatility. They are ideal for environments that require shock absorption and noise reduction.

Steel Wheels

Steel wheels are robust and suitable for heavy-duty applications. They offer superior strength but may not be suitable for environments where corrosion is a concern.

Rubber Wheels

Rubber wheels provide excellent grip and cushioning. They are perfect for applications requiring a non-marking solution, particularly in indoor settings.

4. Essential Maintenance Practices for Drive Wheels

Proper maintenance practices are critical to ensuring that industrial drive wheels perform optimally throughout their lifespan.

Regular Cleaning

Keeping drive wheels clean is essential to prevent the buildup of dirt, grease, and debris. Regular cleaning helps maintain traction and reduces the risk of slippage.

Lubrication

Using the right lubricant can significantly enhance the performance of drive wheels. Regular lubrication minimizes friction and wear, ensuring smoother operation.

5. Regular Inspections: A Key to Longevity

Conducting regular inspections is vital for identifying potential issues before they escalate.

Visual Checks

Employees should be trained to perform visual inspections to spot signs of wear and damage. This includes checking for cracks, uneven wear patterns, and any unusual noises.

Professional Inspections

In addition to routine checks, scheduling professional inspections can help identify underlying issues that may not be visible to the naked eye.

6. Choosing the Right Material for Drive Wheels

The material of the drive wheel significantly affects its performance and durability.

Consider the Environment

When selecting materials, consider the environment in which the wheels will operate. For instance, if exposed to harsh chemicals, wheels made from corrosion-resistant materials are necessary.

Load Capacity

Ensure that the chosen material can handle the operational load without compromising safety or performance.

7. Environmental Factors Affecting Drive Wheel Durability

Various environmental factors can impact the lifespan of industrial drive wheels.

Temperature Extremes

Extreme temperatures can lead to material degradation. It is important to assess the operational temperature range and select materials that can withstand these conditions.

Moisture and Chemicals

Excessive moisture and exposure to chemicals can weaken materials over time. Implementing protective measures, such as coatings, can help mitigate these effects.

8. Troubleshooting Common Drive Wheel Issues

Identifying and troubleshooting common issues can prevent unexpected breakdowns.

Noise Issues

Unusual noises from drive wheels often indicate misalignment or insufficient lubrication. Addressing these issues promptly can prevent further damage.

Vibration Problems

Excessive vibrations can indicate wear or damage. Regular inspections can help identify the root cause, whether it’s a misaligned wheel or a worn-out bearing.

9. Conclusion

Maintaining quality industrial drive wheels is essential for ensuring longevity and optimal performance. By understanding the importance of quality, implementing regular maintenance practices, and being aware of environmental factors, businesses can significantly extend the lifespan of their drive wheels. Investing in quality materials and consistent inspections pays off in efficiency, safety, and cost savings.

10. Frequently Asked Questions

1. How often should I inspect my industrial drive wheels?

Regular inspections should be conducted monthly, with professional inspections at least bi-annually to identify any underlying issues.

2. What are the signs that my drive wheels need replacement?

Signs include cracks, uneven wear, unusual noises, and excessive vibrations. If you notice these issues, it’s time to consider replacing your wheels.

3. Can I use different materials for drive wheels on the same machine?

While it's possible, it’s essential to ensure that the materials used are compatible and meet the necessary load capacity and environmental requirements.

4. What maintenance tasks can I perform myself?

Basic maintenance tasks like cleaning and checking for visible signs of wear can typically be done in-house. However, more in-depth inspections should be left to professionals.

5. How do environmental factors affect drive wheel performance?

Factors such as temperature, moisture, and exposure to chemicals can lead to material degradation and affect the overall performance of drive wheels. Selecting appropriate materials and protective measures can mitigate these effects.

Related news

2026-01-08

A Comprehensive Guide to Extending the Lifespan of Industrial Drive Wheels

A Comprehensive Guide to Extending the Lifespan of Industrial Drive Wheels

Table of Contents

1. Introduction to Industrial Drive Wheels

2. The Importance of Quality Drive Wheels

3. Types of Industrial Drive Wheels

4. Essential Maintenance Practices for Drive Wheels

5. Regular Inspections: A Key to Longevity

6. Choosing the Right Material for Drive Wheels

7. Environment

2025-12-29

New AGV Wheels: The Key to Enhanced Stability in Vehicles

New AGv Wheels: The Key to Enhanced Stability in Vehicles

Table of Contents

1. Introduction to AGV Wheels

2. The Importance of Stability in Vehicle Performance

3. Key Features of New AGV Wheels

3.1 Material Composition

3.2 Wheel Design and Structure

4. Benefits of Enhanced Stability with New AGV Wheels

4.1 Improved Maneuverability

4.2 Increased Load Capacity and Safety

4.3 Redu

2025-12-23

Maximizing Efficiency with Durable AGV Platforms in Freight and Warehousing Logistics

In the fast-evolving world of logistics and freight transportation, the need for efficient, reliable, and durable solutions has never been more critical. Durable AGV platforms are at the forefront of this transformation, providing innovative solutions that streamline operations in warehouses and distribution centers. These platforms are designed to transport goods autonomously, minimizing human in

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License