News Categories

Exploring the Advantages of Upgrading to New AGV Wheels: Enhance Performance and Efficiency

Release time:

2025-07-13

Exploring the Advantages of Upgrading to New AGV Wheels

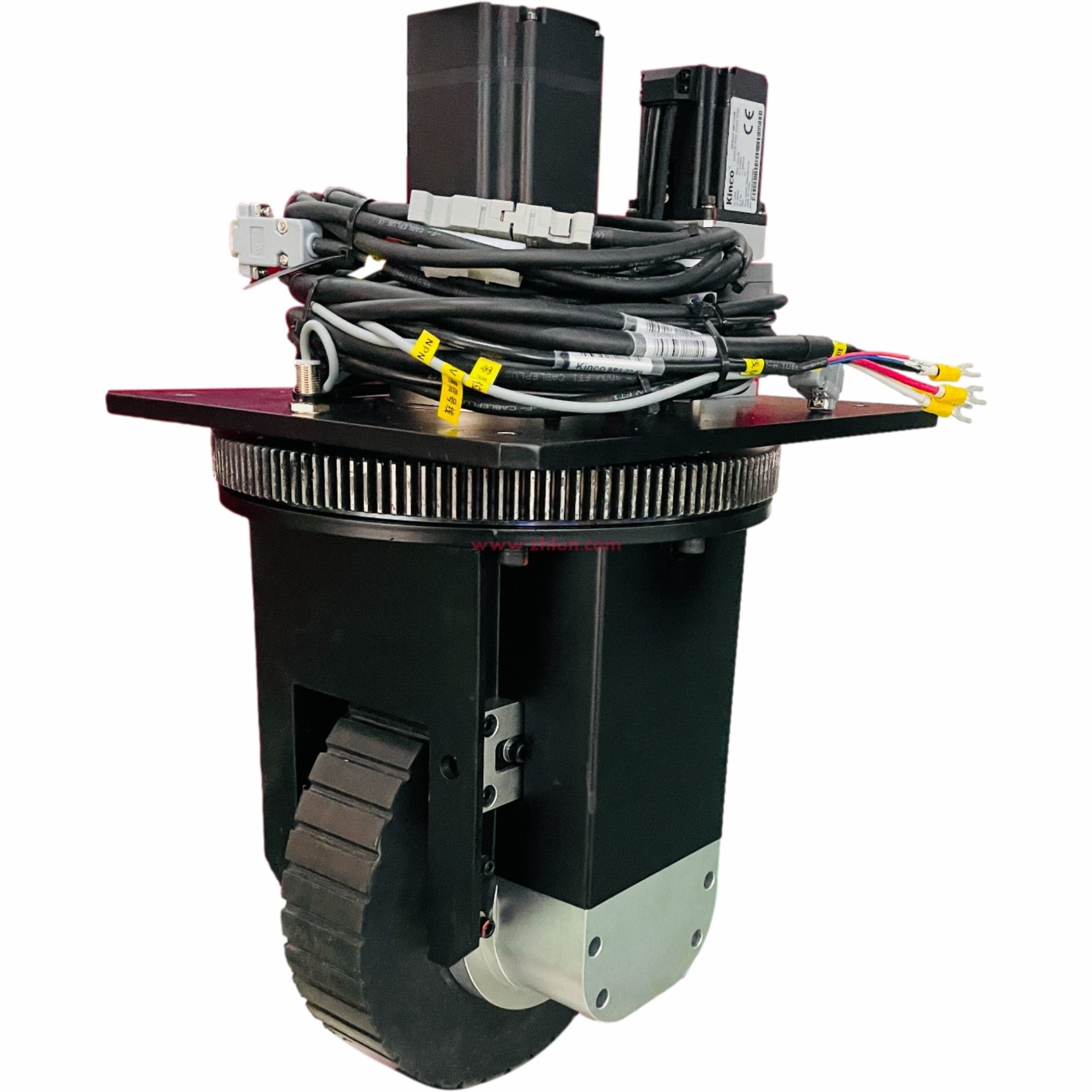

In the ever-evolving landscape of logistics and manufacturing, organizations are continuously seeking ways to enhance operational efficiency. One significant area that often goes overlooked is the wheels of Automated Guided Vehicles (AGVs). Upgrading to new AGV wheels can transform your operations, leading to enhanced performance, reduced maintenance costs, and increased safety. In this article, we will delve into the myriad benefits of upgrading AGV wheels, providing detailed insights into how these changes can help organizations achieve their operational goals.

Understanding AGV Wheels and Their Importance

AGV wheels serve as the crucial interface between the vehicle and the operational surface. They directly impact the vehicle's maneuverability, speed, and overall effectiveness in a warehouse or manufacturing environment. **Understanding the different types of wheels and their applications** is critical in making an informed decision about upgrades.

Types of AGV Wheels

AGV wheels come in various types, each designed for specific functions and environments. The primary types include:

- **Polyurethane Wheels**: Known for their durability and low noise levels, polyurethane wheels are ideal for indoor settings where minimizing noise pollution is essential.

- **Rubber Wheels**: These wheels provide excellent traction and are typically used in environments with different flooring types. They are softer and absorb shocks well, making them suitable for uneven surfaces.

- **Steel Wheels**: Often used for heavy-duty applications, steel wheels can withstand high loads and extreme conditions, making them suitable for outdoor AGVs.

- **Plastic Wheels**: Lightweight and cost-effective, plastic wheels are typically used in lighter AGVs and environments where weight reduction is essential.

Choosing the right wheel type depends on the operational requirements and the environment in which the AGVs will be used.

Key Advantages of Upgrading AGV Wheels

Upgrading AGV wheels can provide extensive benefits that contribute to improved operational efficiency and reduced costs. Let's explore some of the most significant advantages.

1. Enhanced Maneuverability

Upgrading to new AGV wheels can significantly enhance maneuverability. Advanced wheel designs and materials allow for smoother navigation through tight spaces and around obstacles, increasing the overall efficiency of the AGV. This improvement is especially crucial in environments where space is limited, enabling more effective routing and transportation of goods.

2. Improved Load Capacity

New AGV wheels are engineered to handle greater loads than older models. This increase in load capacity means that organizations can transport more materials in a single trip, reducing the number of trips required and thereby increasing overall productivity. **Investing in upgraded wheels ensures that your AGVs can handle the demands of modern logistics operations.**

3. Reduced Maintenance Costs

Old and worn-out wheels often lead to increased maintenance requirements, including frequent replacements and repairs. By upgrading to new AGV wheels, organizations can benefit from improved durability and reduced wear and tear, leading to lower maintenance costs over time. Newer wheel technologies can also provide better resistance to environmental factors, further reducing the need for frequent replacements.

4. Enhanced Safety Features

Safety is paramount in any operational setting. Upgrading to new AGV wheels can improve safety by providing better traction and stability, particularly on uneven or slippery surfaces. Additionally, many modern wheels come equipped with features designed to enhance safety, such as built-in sensors that can help prevent accidents.

5. Increased Speed and Efficiency

New AGV wheels are designed with performance in mind, allowing vehicles to operate at higher speeds without compromising safety or stability. This increase in speed can lead to faster completion of tasks, ultimately enhancing operational efficiency. With improved performance, organizations can meet tighter deadlines and improve customer satisfaction.

Factors to Consider When Upgrading AGV Wheels

While the advantages of upgrading AGV wheels are numerous, several factors need consideration to ensure that the right choice is made for your organization.

1. Operational Environment

The environment in which your AGVs operate plays a significant role in determining the appropriate wheel type. Factors such as floor surface, temperature, and humidity levels should be assessed to ensure the selected wheels meet the operational demands.

2. Load Requirements

Understanding the load requirements of your AGVs is essential when selecting new wheels. Upgrading to wheels that can handle greater loads will maximize efficiency and reduce the risk of overstressing the vehicle or its components.

3. Wheel Material

The material of the AGV wheels impacts performance characteristics such as durability, grip, and noise levels. Selecting the right material based on your operational requirements will enhance overall vehicle performance.

4. Compatibility with Existing Systems

Before making any upgrades, it is crucial to assess the compatibility of new wheels with existing AGV systems. Ensuring that the new wheels integrate seamlessly with your current technology is essential to prevent operational disruptions.

Maintenance Tips for Upgraded AGV Wheels

To maximize the benefits of upgraded AGV wheels, regular maintenance is crucial. Here are some essential maintenance tips to keep your new wheels in optimal condition:

1. Regular Inspections

Conduct routine inspections of your AGV wheels to identify any signs of wear and tear. Early detection of issues can prevent more significant problems down the line.

2. Cleanliness

Keeping the wheels clean will help maintain traction and performance. Dust, debris, and grease can accumulate on the wheels, affecting their functionality.

3. Lubrication

Proper lubrication of wheel bearings and components is essential for smooth operation. Ensure that the lubrication schedule is adhered to as per the manufacturer’s recommendations.

4. Monitor Load Distribution

Ensure that loads are evenly distributed across the AGV to prevent undue stress on the wheels. Uneven loads can lead to faster wear and increased maintenance needs.

Insights from Industry Experts

Industry experts consistently emphasize the importance of upgrading AGV wheels to maintain competitiveness in the logistics sector. According to a study by the International Society of Automation, organizations that invest in advanced AGV technologies, including wheel upgrades, see a marked improvement in their operational performance.

Expert Recommendations

- **Evaluate Your Needs Regularly**: Conduct assessments of your AGV performance and requirements to ensure your fleet remains updated with the latest technology.

- **Stay Informed About Trends**: Keep abreast of innovations in AGV wheel technology to ensure you’re not missing out on performance-enhancing opportunities.

- **Consult with Manufacturers**: Engage with AGV manufacturers to understand what options are available and which upgrades would be most beneficial for your specific context.

Frequently Asked Questions (FAQs)

1. How do I know when to upgrade my AGV wheels?

Regular inspection and monitoring of performance metrics can help determine when an upgrade is necessary. Signs such as reduced maneuverability, increased noise, or visible wear may indicate the need for new wheels.

2. What types of surfaces are suitable for AGV wheels?

AGV wheels can be designed for various surfaces, including concrete, asphalt, and even specialized flooring. Selecting the correct wheel type based on the surface will enhance performance.

3. Are new AGV wheels compatible with all AGV models?

Not all new wheels may be compatible with existing AGV models. It’s essential to consult with manufacturers to ensure proper fit before purchasing new wheels.

4. What is the lifespan of AGV wheels?

The lifespan of AGV wheels can vary significantly based on usage, load, and environmental conditions. On average, well-maintained wheels can last between 1 to 5 years.

5. Can I upgrade AGV wheels myself?

While some organizations may have the technical expertise to upgrade AGV wheels, consulting with professionals or manufacturers is recommended to ensure proper installation and functionality.

Conclusion

Upgrading to new AGV wheels is a strategic move that offers numerous advantages for organizations looking to enhance their operational efficiency. From improved maneuverability and load capacity to reduced maintenance costs and increased safety, the benefits are clear. By carefully considering the various factors involved in the selection and maintenance of AGV wheels, organizations can ensure they maximize the performance and longevity of their AGV fleets. Embracing this technological advancement is essential for staying competitive in today’s fast-paced logistics and manufacturing environments.

Related news

2025-07-13

Exploring the Advantages of Upgrading to New AGV Wheels: Enhance Performance and Efficiency

Exploring the Advantages of Upgrading to New AGV Wheels

In the ever-evolving landscape of logistics and manufacturing, organizations are continuously seeking ways to enhance operational efficiency. One significant area that often goes overlooked is the wheels of Automated Guided Vehicles (AGVs). Upgrading to new AGV wheels can transform your operations, leading to enhanced performance, reduced mai

2025-07-08

Unleashing Efficiency: The Importance of Durable AGV Platforms in Logistics

In the fast-paced world of logistics and cargo transportation, efficiency and reliability are paramount. One of the key components that contribute to seamless operations in warehouses and distribution centers is the deployment of durable Automated Guided Vehicle (AGV) platforms. These technological marvels are designed to handle various tasks, from transporting goods to streamlining warehouse mana

2025-07-03

Top Features to Look for in Quality Industrial Drive Wheels

Top Features to Look for in Quality Industrial Drive Wheels

Industrial drive wheels are crucial components in various machinery, facilitating movement and enhancing efficiency. Selecting the right wheels can significantly impact operational effectiveness, safety, and longevity. This article delves into the key features one should consider when choosing quality industrial drive wheels, ensuring opt

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License