News Categories

Exploring the Benefits of Quality Industrial Drive Wheels for Enhanced Operational Efficiency

Release time:

2025-05-24

Exploring the Benefits of Quality Industrial Drive Wheels for Enhanced Operational Efficiency

Table of Contents

- 1. Introduction to Industrial Drive Wheels

- 2. Importance of Quality in Drive Wheels

- 3. Types of Industrial Drive Wheels

- 4. Key Benefits of Quality Industrial Drive Wheels

- 5. How to Select Quality Industrial Drive Wheels

- 6. Maintenance Tips for Industrial Drive Wheels

- 7. Applications of Industrial Drive Wheels

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Industrial Drive Wheels

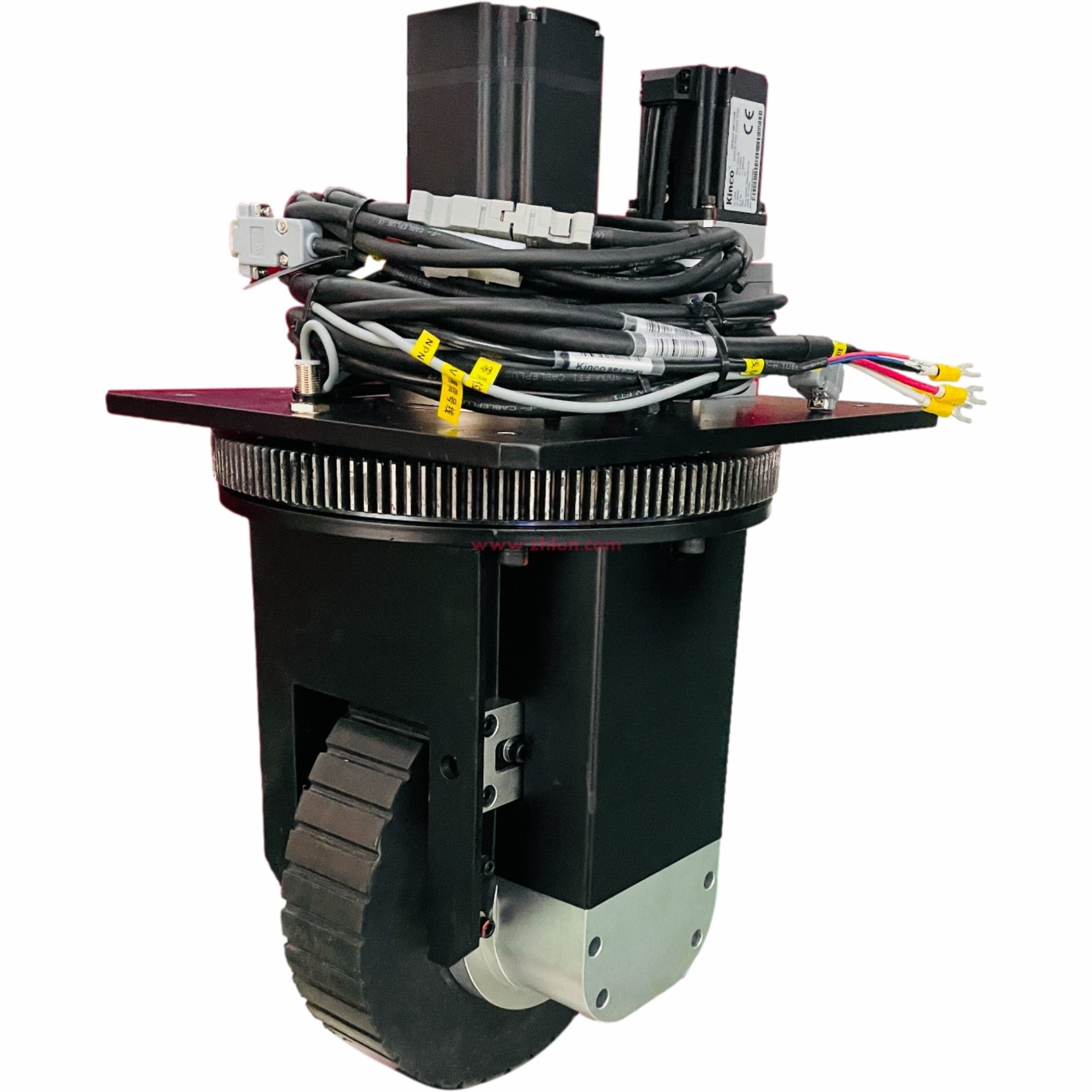

Industrial drive wheels play a crucial role in the smooth operation of various machinery and vehicles within the manufacturing and logistics sectors. These wheels are designed to transfer mechanical power and provide mobility to equipment ranging from forklifts to conveyor systems. Understanding their significance, types, and benefits can greatly enhance productivity and operational efficiency.

2. Importance of Quality in Drive Wheels

The quality of industrial drive wheels directly impacts overall performance and safety. High-quality materials and manufacturing processes ensure durability, resistance to wear, and the ability to withstand harsh operating conditions. Investing in quality drive wheels mitigates risks and promotes system reliability, thereby safeguarding your operational investments.

3. Types of Industrial Drive Wheels

There are various types of industrial drive wheels, each designed to meet specific operational requirements. Understanding these types can help you choose the right wheels for your needs.

3.1 Solid Rubber Wheels

Solid rubber wheels are known for their shock absorption and quiet operation. They are ideal for indoor environments where noise reduction is crucial.

3.2 Polyurethane Wheels

Polyurethane wheels offer superior wear resistance and load-bearing capacity. They are suitable for both indoor and outdoor applications and provide excellent traction.

3.3 Pneumatic Wheels

Pneumatic wheels are filled with air, offering enhanced cushioning and shock absorption. They are particularly effective on uneven surfaces and in outdoor applications.

3.4 Steel Wheels

Steel wheels provide exceptional durability and load-bearing capabilities. They are often used in heavy-duty industrial applications where strength is paramount.

4. Key Benefits of Quality Industrial Drive Wheels

Investing in quality industrial drive wheels yields numerous advantages that positively impact your operations.

4.1 Enhanced Operational Efficiency

Quality industrial drive wheels contribute to enhanced operational efficiency through improved load handling, reduced friction, and optimized power transmission. This results in smoother operations and higher productivity levels, allowing your business to meet demands more effectively.

4.2 Improved Safety Standards

Safety is a top priority in any industrial setting. Quality drive wheels minimize the risk of accidents by providing reliable performance and stability. They reduce the likelihood of equipment failures and ensure safe transportation of goods, thus protecting both employees and assets.

4.3 Long-Term Cost Savings

While initial costs may be higher, investing in quality industrial drive wheels leads to significant long-term savings. Durable wheels require less frequent replacement, reducing maintenance costs and minimizing downtime. This ultimately contributes to improved profitability.

5. How to Select Quality Industrial Drive Wheels

Choosing the right industrial drive wheels involves considering various factors to ensure optimal performance and reliability.

5.1 Load Capacity

Evaluate the load capacity requirements of your specific applications. Ensure that the chosen wheels can handle the maximum weight you expect to transport.

5.2 Surface Conditions

Consider the surfaces on which the wheels will operate. Different wheel materials perform better on various terrains, so select accordingly.

5.3 Speed Requirements

The speed at which equipment operates can influence wheel selection. Ensure that the wheels are designed to perform efficiently at your operational speeds.

5.4 Environmental Factors

Evaluate environmental conditions, including temperature extremes, exposure to chemicals, and moisture levels. Choose wheels made from materials that can withstand these conditions.

6. Maintenance Tips for Industrial Drive Wheels

Proper maintenance of industrial drive wheels can extend their lifespan and ensure optimal performance.

6.1 Regular Inspections

Conduct regular inspections to check for wear and tear. Look for signs of damage, cracks, or deformation that may affect performance.

6.2 Cleaning

Keep wheels clean and free from debris. Dirt and grime can accumulate and affect traction and performance, leading to increased wear.

6.3 Lubrication

Apply appropriate lubricants to reduce friction and enhance performance. Ensure that any bearings associated with the wheels are well-lubricated.

7. Applications of Industrial Drive Wheels

Industrial drive wheels find application in various sectors, enhancing operational efficiency across different industries.

7.1 Manufacturing

In manufacturing, drive wheels are essential for moving materials, operating machinery, and facilitating assembly lines.

7.2 Warehousing

In warehouses, drive wheels are critical for forklifts and pallet jacks, enabling the efficient movement of goods and inventory management.

7.3 Transportation

Transportation industries utilize drive wheels in vehicles for transporting goods over long distances, ensuring reliability and safety.

8. Conclusion

In conclusion, the benefits of quality industrial drive wheels cannot be overstated. They enhance operational efficiency, improve safety standards, and provide long-term cost savings, all of which are crucial for maintaining a competitive edge in today's fast-paced industrial landscape. By understanding the different types of wheels available and following best practices for selection and maintenance, businesses can make informed decisions that lead to optimal performance and reliability.

9. Frequently Asked Questions

9.1 What are industrial drive wheels?

Industrial drive wheels are specialized wheels used in various machinery and vehicles to facilitate movement and transfer power in industrial settings.

9.2 How do I know which type of drive wheel is best for my application?

Consider factors such as load capacity, surface conditions, speed requirements, and environmental factors when selecting the most suitable type for your application.

9.3 How often should I inspect and maintain my drive wheels?

Regular inspections should be conducted at least once a month, while maintenance tasks like cleaning and lubrication should be performed more frequently based on usage.

9.4 Can quality drive wheels reduce operational costs?

Yes, investing in quality drive wheels can lead to long-term savings by reducing the need for frequent replacements and minimizing maintenance costs.

9.5 Where can I purchase quality industrial drive wheels?

Quality industrial drive wheels can be purchased from specialized suppliers, manufacturers, or online marketplaces that focus on industrial equipment and parts.

Related news

2025-05-26

New AGV Platforms represent the latest innovation in automated guided vehicle technology, designed to revolutionize material handling and logistics across various industries. These advanced platforms offer enhanced precision, flexibility, and efficiency, making them indispensable tools for modern warehouses, manufacturing plants, and distribution centers. The New AGV Platforms are engineered to navigate complex environments autonomously, providing reliable transport of goods without the need for manual intervention.

2025-05-24

Exploring the Benefits of Quality Industrial Drive Wheels for Enhanced Operational Efficiency

Exploring the Benefits of Quality Industrial Drive Wheels for Enhanced Operational Efficiency

Table of Contents

1. Introduction to Industrial Drive Wheels

2. Importance of Quality in Drive Wheels

3. Types of Industrial Drive Wheels

4. Key Benefits of Quality Industrial Drive Wheels

4.1 Enhanced Operational Efficiency

4.2 Improved Safety Standards

4.3 Long-Term Cost

2025-05-19

Exploring the Best Motor Drive Wheels: Essential Insights for Optimal Performance

Motor drive wheels are pivotal elements in the functioning of various electric vehicles, including motorcycles, scooters, and even some automotive applications. These wheels are designed to convert electrical energy into mechanical energy, allowing for efficient propulsion and control. When seeking the "best motor drive wheel," several factors come into play that can significantly influence perfor

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 8, Longhe Westroad,

Longgui, Taihe Town, Guangzhou, Guangdong.China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct

License