编号 :

ZL-B320

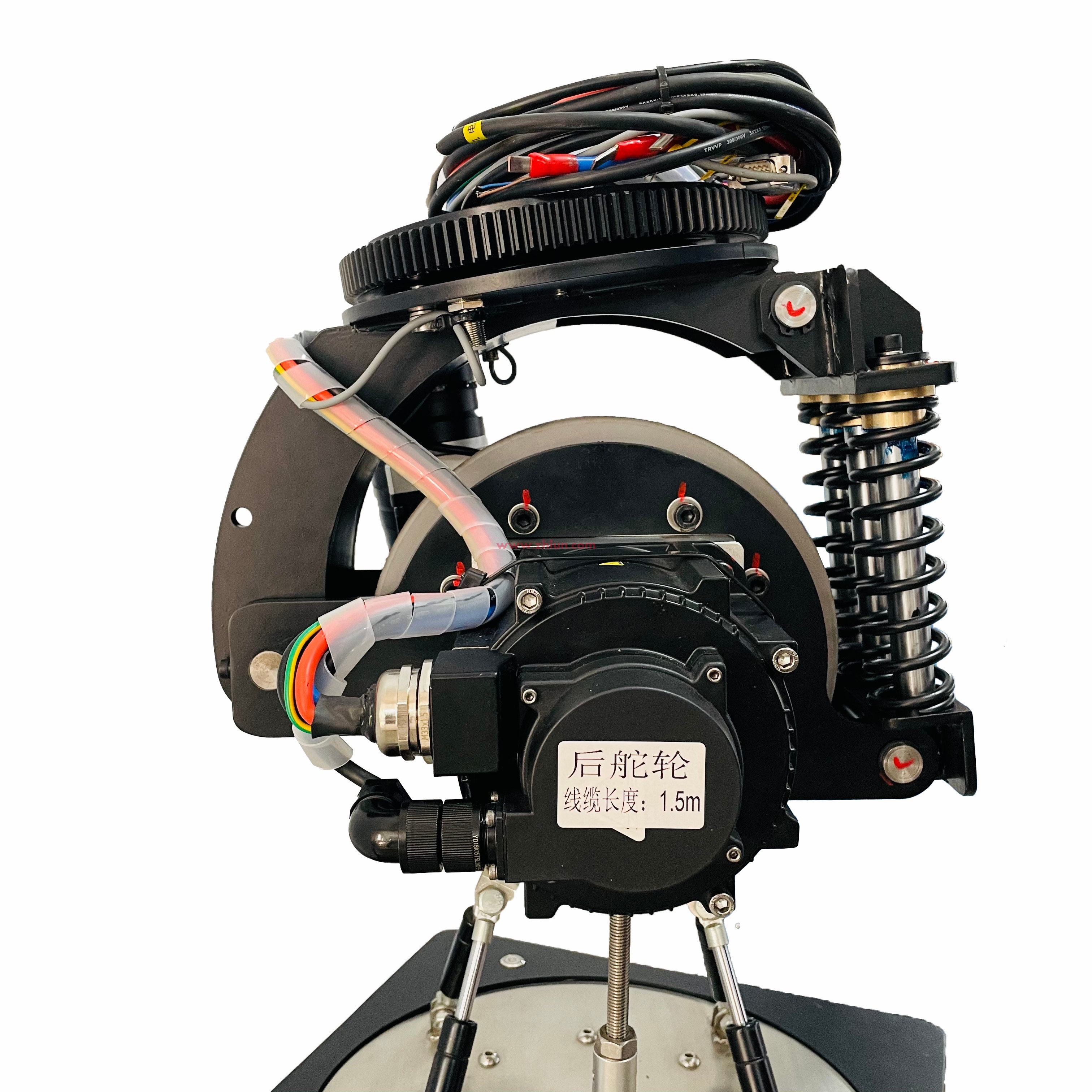

Drive Steering Wheel ZL-B320: Empowering AGV and Heavy-Duty Operations, Reshaping the New Benchmark of Industrial Mobility Efficiency

Product number:ZL-B320

隐藏域元素占位

- Product description

-

Drive Steering Wheel ZL-B320: Empowering AGV and Heavy-Duty Operations, Reshaping the New Benchmark of Industrial Mobility Efficiency

Against the backdrop of rapid development in industrial automation and intelligent logistics, equipment such as AGVs (automated guided vehicles) and intelligent handling robots are placing increasingly stringent demands on core power components.These components need to not only bear stable heavy loads and adapt to complex ground environments but also match the precise control needs of automated equipment. Based on a 1000KG rated load, the drive steering wheel ZL-B320, with its large-diameter rubber wheel surface, strong ground adaptability, and diversified motor configurations, has become the core power choice for AGVs, intelligent warehouse robots, and industrial heavy-duty handling equipment, providing reliable support for the automation upgrading of multiple industries

Core Performance: Tailor-Made for AGV and Heavy-Duty Scenarios

1. 1000KG Rated Load: Stable Loading, Adapting to Mainstream Heavy-Duty Requirements

The 1000KG rated load of ZL-B320 accurately matches the load-bearing needs of medium-sized AGVs and intelligent handling robots. Whether it is the goods transfer of e-commerce warehouse AGVs, the material distribution in auto parts workshops, or the semi-finished product handling in the 3C manufacturing field, it can easily bear the full-load weight. Its high-strength wheel structure and high-quality load-bearing components have undergone strict load tests, and are not prone to deformation or performance degradation during long-term continuous operations. This ensures that AGVs and other equipment operate stably at all links such as sorting, transfer, and docking, avoiding operational interruptions caused by insufficient load-bearing capacity of power components.

2. Large-Diameter Rubber Wheel Surface + Strong Friction: "Stability Guarantee" for AGV Travel on Complex Ground

Aiming at the multi-scenario ground conditions commonly encountered by AGVs, such as workshop cement floors, warehouse epoxy floors, and logistics park asphalt roads, the ZL-B320 adopts a large-diameter rubber wheel surface design. On one hand, the large diameter effectively reduces the contact pressure between the wheel surface and the ground, minimizing wear on the warehouse epoxy floor. At the same time, it improves driving stability and prevents material deviation caused by jolts when AGVs move at high speeds. On the other hand, the rubber material inherently has high elasticity and wear resistance, which not only extends the service life of the wheel surface (the service life can be increased by more than 30% compared with ordinary polyurethane wheel surfaces) but also provides extremely strong ground friction. Even on wet or slightly oily workshop floors, it can eliminate the risk of slipping, ensuring that AGVs travel accurately along the path during automatic guidance and meeting the strict "zero deviation" requirement of automated operations.

3. Built-in drive motor + excellent obstacle crossing capability: Break through site restrictions and improve AGV traffic efficiencyThe ZL-B320 adopts a built-in drive motor design, which highly integrates the power system with the wheel body. This significantly reduces the installation space of AGVs and other equipment, facilitating the overall structural optimization of the equipment (especially suitable for the compact design needs of narrow-body AGVs and latent AGVs). More importantly, its excellent obstacle-crossing ability perfectly solves the "pain point" of AGVs in actual operations. When facing raised floor joints in workshops, stones in warehouses, and slight thresholds (height ≤ 30mm) in logistics channels, it can easily cross them without additional auxiliary obstacle-crossing devices.. This avoids AGV alarms triggered by obstacle stagnation and ensures the continuity of "unmanned" operations in automated production lines and intelligent warehouses.

Diversified Configurations: Matching Personalized Needs of AGVs and Multi-Industry Equipment

1. Four Motor Options: Covering All Scenarios from Precise Control to Explosion-Proof Safety

ZL-B320 offers four configuration options: actuating motors, brushless motors, stepper motors, and explosion-proof motors, accurately adapting to the functional needs of different AGVs and industrial equipment:

Actuating Motor: Equipped with millisecond-level speed and position response capabilities, it is suitable for high-precision AGVs (such as AGVs for precision component transfer in the 3C industry and AGVs in sterile environments in the pharmaceutical industry). It ensures that the error of AGVs is ≤ ±1mm when docking with production lines and parking accurately, meeting the "high-precision collaboration" requirement of automated production.

Brushless Motor: Characterized by high efficiency and energy saving (energy consumption is 25% lower than that of traditional brushed motors), low noise (operating noise ≤ 60dB), and long service life (service life up to more than 10,000 hours), it is suitable for scenarios that require 24-hour continuous operations, such as e-commerce warehouse AGVs and logistics sorting robots, reducing equipment operation and maintenance costs and workshop noise pollution.

Stepper Motor: Supports precise step control and is suitable for equipment that requires fixed-distance movement (such as AGVs for intelligent shelf handling and auxiliary robots in assembly lines). It can achieve "fixed-distance movement" without complex sensor calibration, simplifying the equipment control logic.

Explosion-Proof Motor: Compliant with the GB3836.1-2010 explosion-proof standard, it is suitable for AGVs in flammable and explosive environments such as chemical industry, petroleum, and pharmaceutical industry (such as AGVs for chemical raw material transfer and oilfield inspection robots). It eliminates the safety hazard of explosions caused by electric sparks generated during motor operation, ensuring the safety of automated operations in special scenarios.

2. Flexible Parameter Customization: Full-Dimensional Adaptation to Equipment from Brake to Power

In view of the differences in technical parameters of different AGVs and industrial equipment, the built-in brake, speed ratio, and power of the ZL-B320 can be fully configured according to needs. For example, to meet the "emergency braking" requirement of AGVs, a high-response electromagnetic brake (braking response time ≤ 0.2 seconds) can be customized to avoid the risk of sliding in emergency situations of AGVs. For climbing AGVs (such as the slope channels of warehouse stereoscopic libraries), a large speed ratio and high-power motor can be matched to ensure that the equipment can travel on slopes within 15° without slipping under full load. For low-energy-consuming AGVs, power parameters can be optimized, and combined with brushless motors to achieve "low power consumption and long battery life", adapting to the long-term operation needs of outdoor inspection AGVs.

In addition, the product fully supports non-standard customization. Whether it is the special installation size of AGVs (such as narrow wheelbase and special flange interface), the upgrade of wheel surface materials (such as oil-resistant rubber and anti-static rubber), or the addition of sensor integration (such as wheel speed sensors and temperature monitoring modules), the professional engineer team can follow up the entire process from design, prototyping to production, ensuring the "seamless connection" between the ZL-B320 and the customer's equipment.

Application Scenarios: Covering Multiple Industries and Empowering Automation Upgrading

1. Intelligent Logistics and Warehousing: The “Core Power Source” of AGVs

In e-commerce warehouses and third-party logistics centers, the ZL-B320 is the core power component of latent AGVs and forklift AGVs. The 1000KG load can meet the transfer needs of 2-3 standard pallets. The large-diameter rubber wheel surface travels stably on the warehouse epoxy floor, and the strong friction ensures that AGVs can turn and park accurately in sorting areas and shelf channels. In cold chain warehouse scenarios, the combination of low-temperature resistant rubber wheel surfaces (customizable -30℃ low-temperature resistant version) and explosion-proof motors can adapt to the low-temperature and refrigerant environment operation needs of cold chain AGVs, helping warehouse logistics upgrade from "manual handling" to "unmanned transfer".

2. Industrial Manufacturing: The "Mobile Link" of Production Lines and Workshops

In auto parts manufacturing workshops, the ZL-B320 is adapted to heavy-duty AGVs for cross-workshop transfer of heavy components such as engines and gearboxes. Its excellent obstacle-crossing ability can easily handle the raised track joints and equipment bases on the workshop floor. In 3C electronics factories, the ZL-B320 equipped with actuating motors can cooperate with precision AGVs to achieve "zero vibration" transfer of fragile components such as mobile phone motherboards and screens, meeting the high requirements of electronic manufacturing for precision and stability. In chemical parks, the explosion-proof motor version of the ZL-B320 provides safe power for hazardous chemical transfer AGVs, eliminating safety hazards during operation.

3. Special Scenarios: Expanding the "Boundary" of Industrial Mobility

In addition to traditional industrial scenarios, the ZL-B320 can also be adapted to special operation equipment. In new energy battery production workshops, the anti-static rubber wheel surface version can avoid static damage to battery cells. On AGV parking robots in Intelligent parking lots, its strong obstacle-crossing ability can handle the speed bumps and slight slopes on the parking lot ground, realizing the rapid handling and parking of vehicles. In semi-enclosed outdoor scenarios (such as short-distance transfer of port containers and heavy material transportation in factory areas), the wear-resistant rubber wheel surface and high protection level (customizable IP65 protection) can resist wind, rain, and ground gravel wear, extending the service life of the equipment.

Future Development: Keeping Up with Automation Trends and Opening Up a New Blue Ocean for Power Components

With the in-depth advancement of "Industry 4.0" and "Intelligent Logistics", drive steering wheels, as the "core power unit" of AGVs and intelligent robots, will usher in three major development directions in the future, and the ZL-B320 will continue to iterate to adapt to industry needs:

1. Intelligent Upgrading: Integrating into the Industrial Internet to Achieve "Perceptible Status and Predictable Faults"

In the future, the ZL-B320 will gradually integrate intelligent sensor modules (such as temperature sensors, vibration sensors, and wheel speed sensors). Through data interfaces, it will connect with the AGV control system and factory MES system to monitor the operating temperature, load status, and wear degree of the steering wheel in real time. When the wheel surface wear reaches the threshold or the motor temperature is abnormal, it can send an early warning signal in advance to realize "predictive maintenance", avoiding sudden failures of AGVs during operation and further improving the reliability of automated production lines. At the same time, it will optimize the operating parameters of the steering wheel through data (such as adjusting power output according to load), achieving more precise energy consumption control.

3. Green and Energy-Saving: Responding to the "Dual Carbon" Goal and Optimizing Power Efficiency

Driven by the "dual carbon" policy, the requirements for energy consumption of industrial equipment are becoming increasingly strict. The ZL-B320 will further optimize motor efficiency (aiming to reduce the energy consumption of brushless motors by another 15%) and explore new environmentally friendly wheel surface materials (such as recyclable rubber and bio-based elastic materials), reducing environmental impact while ensuring performance. At the same time, through lightweight structural design (such as using high-strength aluminum alloy materials), it will reduce the weight of the steering wheel itself, reducing the power loss of AGVs and helping enterprises achieve the goal of "green production".

Conclusion: Choose ZL-B320 to Seize the "Power Opportunity" for Automation Upgrading

The drive steering wheel ZL-B320 is not only a power component that meets the requirements of "1000KG load, strong obstacle-crossing ability, and multiple motor options" but also a "customized power solution" adapted to AGVs and multi-industry automated equipment. From intelligent warehousing to industrial manufacturing, from traditional scenarios to emerging fields, it provides "reliable power support" for enterprises' automation upgrading with its stable performance, flexible configuration, and expandable future potential. Whether it is the current AGV equipment transformation or the future intelligent robot research and development, choosing the ZL-B320 will enable your equipment to have stronger competitiveness in the "wave of industrial automation" and seize the dual advantages of efficiency and cost.

Related products

undefined

Products Message

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct