编号 :

3Tons ZL-D500 Heavy-Duty Differential Drive Wheel Assembly for Industrial Robots and Automated Guided Vehicles

Product number:

隐藏域元素占位

- Product description

-

3 Tons ZL-D500 Heavy-Duty Differential Drive Wheel Assembly for Industrial Robots and Automated Guided Vehicles

I. Structural

A 3-ton differential drive wheel assembly is a highly integrated mechatronic system, far more than just a simple wheel. It consists of the following core components:

1. Heavy-Duty Wheel and Tire

Material: The wheel hub is typically made of high-strength alloy steel or forged steel to ensure it can withstand significant radial and axial loads.

Rubber Tire: Provides improved shock absorption and grip, suitable for rough surfaces.

Design: The wide wheel tread reduces ground pressure (psi), preventing sinking and improving stability.

2. Differential

This is the heart of the entire drive unit and the reason for its name. Its structure is similar to that of an automotive differential, but reinforced for industrial applications.Function: When an AGV turns, the left and right wheels travel different lengths. The differential automatically distributes torque and speed to the left and right wheels, allowing the outer wheel to rotate faster and the inner wheel to rotate slower, resulting in stable, slip-free turns and reduced tire wear and energy consumption.

3. High-Torque Drive Motor

Type: Servo DC motors are typically used for their high efficiency, high torque, long life, and maintenance-free design.

Integration: The motor is typically integrated with the drive wheel assembly (built-in), resulting in a compact, space-saving design. Motor power is typically in the kilowatt range to ensure it can provide the massive torque required for starting and pushing a 3-ton load.

4. High-Reduction-Ratio Planetary Gearbox

Function: Motors typically operate at high speeds and low torque. The gearbox significantly reduces the motor's speed while amplifying its torque by a factor of the reduction ratio to meet the requirements of heavy-load, low-speed operation.

5. Brake

Function: Safe braking is crucial for heavy-duty AGVs carrying loads up to 3 tons. Electromagnetic brakes are typically integrated.

Operating Principle: Releases when powered on and brakes immediately when powered off. This is a safety feature that prevents vehicle loss of control in the event of an unexpected power outage or system failure, ensuring safety.

6. Encoder

Function: The high-precision encoder integrated into the motor provides real-time motor speed and position feedback to the AGV controller. This is a key sensor for precise speed control, odometry positioning, and synchronization.

II. Application

1. Core Application Scenarios

This level of heavy-duty differential drive is primarily used in applications with extremely high load and capacity requirements:Automotive: Transporting car bodies, chassis, engine assemblies, and large molds.

Aerospace: Moving aircraft parts and engines.

Heavy-Duty Logistics and Warehousing: Automated handling of large containers, heavy-duty shelving units, and large industrial products.

Ports and Terminals: Used in AGVs handling large containers.

Specialty Industries: Applications such as heavy machinery manufacturing and handling large transformers.

2. Core Role in the AGV System

Providing Core Power: It is the sole source of power for AGV movement.

Enabling Flexible Steering: The differential function is the foundation of the AGV's two-wheel differential steering. By controlling the speed difference between the left and right drive wheels (one fast, one slow, one forward, one reverse), the AGV can easily move straight, turn, and even rotate on the spot, significantly saving turning space and improving flexibility.

Ensuring Stable Operation: The differential device eliminates forced drag during turns, ensuring better operation and protecting cargo from sharp turns or bumps.

Contributing to Navigation Accuracy: Encoder data is a key input for the AGV to calculate its own travel distance and angle (dead reckoning), assisting systems such as laser navigation and inertial navigation to achieve high-precision positioning.

In summary, the 3-ton differential drive wheel is the "heart" and "legs" of the heavy-duty AGV. It is a high-tech product that Integrated mechanical drive, motor drive, and sensor feedback. Its high load capacity and flexible steering capabilities based on the differential enable safe and efficient movement of multi-ton cargo within confined spaces, making it an indispensable key component in automated heavy-duty logistics.

Related products

undefined

Products Message

Products

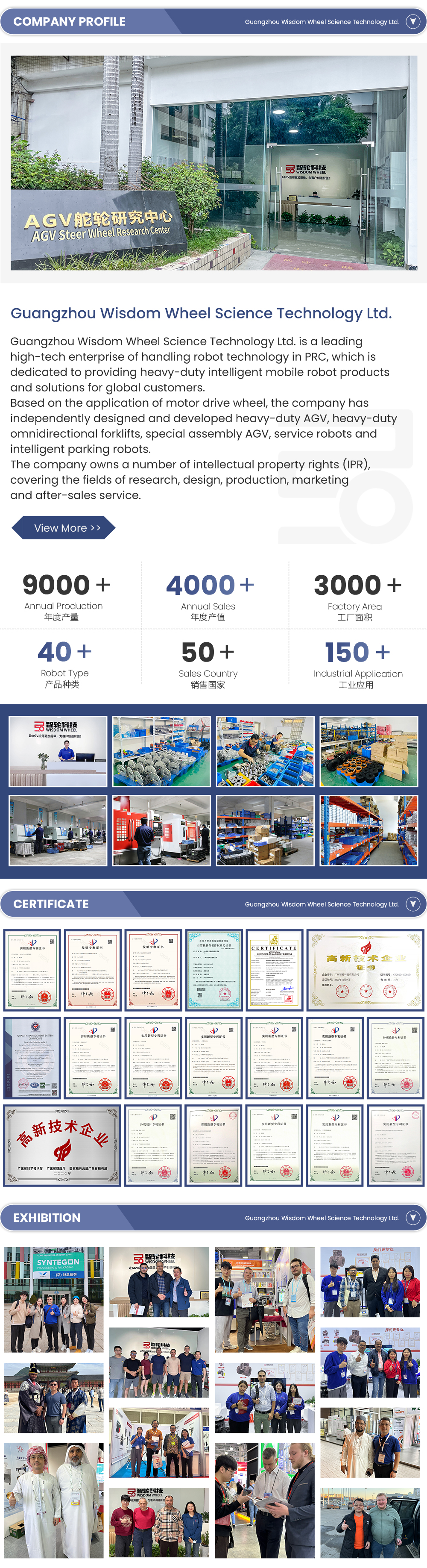

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct