编号 :

Vertical drive wheel: ideal for efficient power transfer and precise control

Product number:

隐藏域元素占位

- Product description

-

High-performance vertical driving wheel: Provides powerful driving force with versatile equipment

1. Structure and composition

Vertical drive wheels usually consist of the following key components:

Wheels: Made of wear-resistant materials (such as rubber, polyurethane, etc.), provide good grip and friction, and adapt to different ground conditions.

Motor: As a power source, common types include DC motors, stepper motors and servo motors, and different powers and speeds can be selected according to needs.

Bearings: Support wheel rotation, reduce friction, and ensure steady operation.

Bracket: Used to fix wheels and motors, usually designed to be adjustable, easy to install and adapt to different equipment.

Encoder (optional): Used to accurately control the speed and position of the wheel, suitable for high-precision application scenarios.2.Advantages:

Efficient power transfer: Direct drive reduces energy loss and increases efficiency.

Precise control: Combined with encoder and control system, high-precision speed and position control can be achieved.

Compact structure: Vertical design saves space and is suitable for miniaturized and lightweight equipment.

Strong stability: Vertical layout helps to keep the equipment balanced and run more stably.

Strong adaptability: Wheel material, motor type and power can be selected according to different needs to adapt to a variety of application scenarios.

3. Selection points:

When choosing a vertical drive wheel, consider the following factors:

Load capacity: Select suitable wheels and motors according to the weight of the equipment.

Speed requirements: Select the speed and power of the motor according to the application scenario.

Ground conditions: Select suitable wheel materials (such as rubber, polyurethane, etc.) to adapt to different ground conditions.

Control accuracy: For high-precision applications, choose a drive wheel with an encoder.

Environmental adaptability: Consider the temperature, humidity, corrosiveness and other factors of the working environment, and choose durable materials and protection levels.4.Working principle:

The vertical drive wheel drives the wheel to rotate through the motor, converting electrical energy into mechanical energy, thereby driving the device to move. Its working principle is as follows:

The motor receives the control signal and drives the wheel to rotate at a specific speed and direction.

By adjusting the speed and direction of the motor, the device can move forward, backward, turn, etc.

In scenarios that require high-precision control, the encoder can provide real-time feedback on the movement state of the wheel to achieve closed-loop control.

5.Application scenarios

Vertical drive wheels are widely used in the following fields due to their high efficiency and flexibility:

Mobile robots: used for service robots, cleaning robots, etc., to provide precise motion control.

Automated guided vehicles (AGVs): used for automated transportation and handling in warehousing, logistics, and manufacturing.

Power wheelchairs and medical equipment: providing fluent power delivery and controllability to enhance the user experience.

Industrial equipment: used for mobile equipment on production lines, such as material handling vehicles, assembly platforms, etc.

Summary:

As an efficient and flexible power transfer device, the vertical drive wheel plays an important role in automation equipment.Whether it is industrial application or consumer product, it can provide reliable power support and precise motion control .With the advancement of technology, the vertical drive wheel will continue to promote the development of automation and bring convenience and innovation to more industries.

If you have specific needs or technical questions, please feel free to discuss further!

Related products

undefined

Products Message

Products

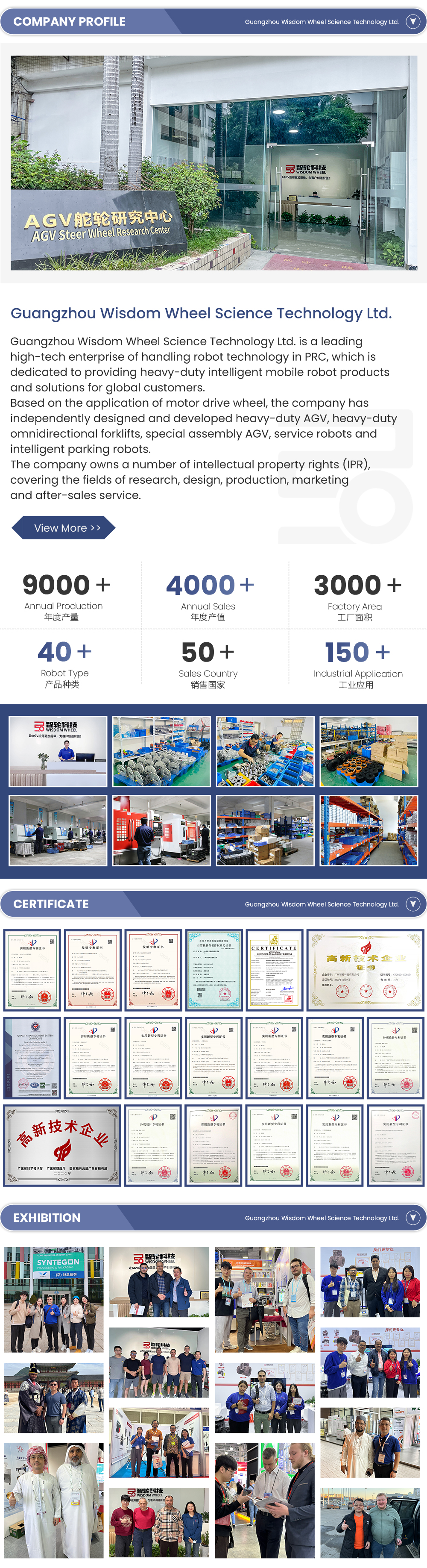

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct