编号 :

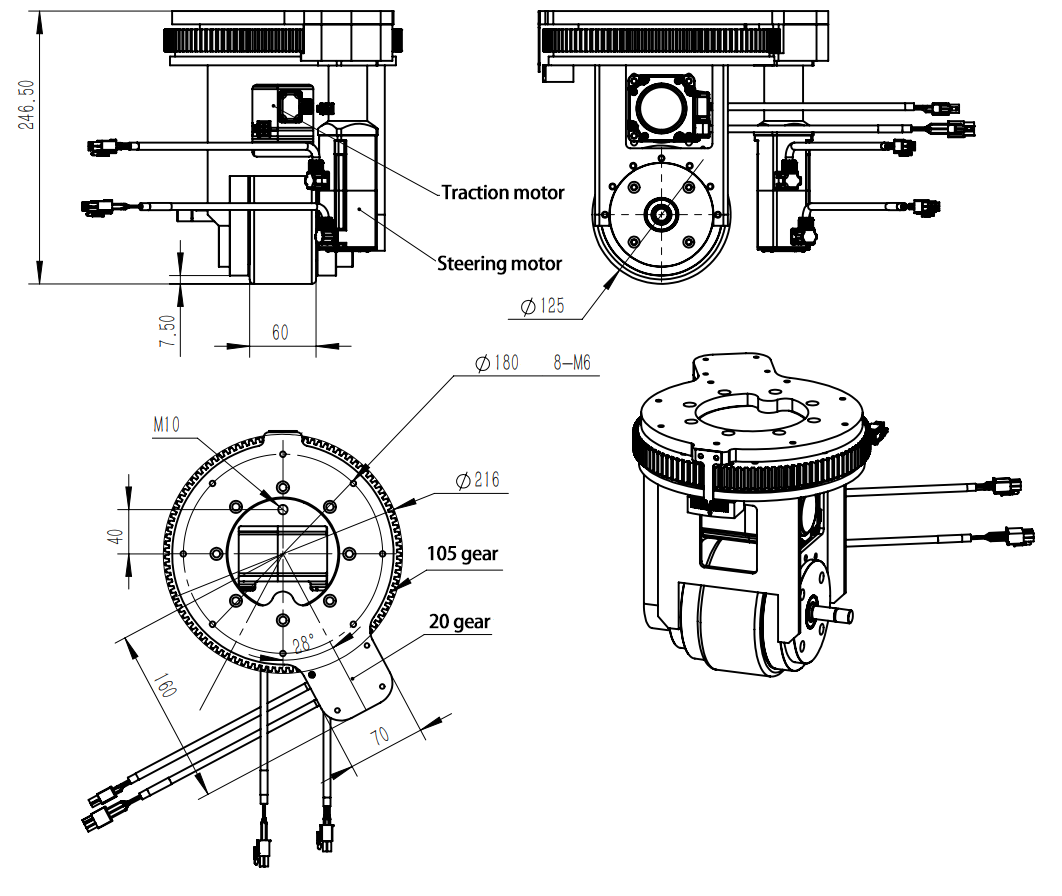

Model V245 For 300KG

Product number:

隐藏域元素占位

- Product description

-

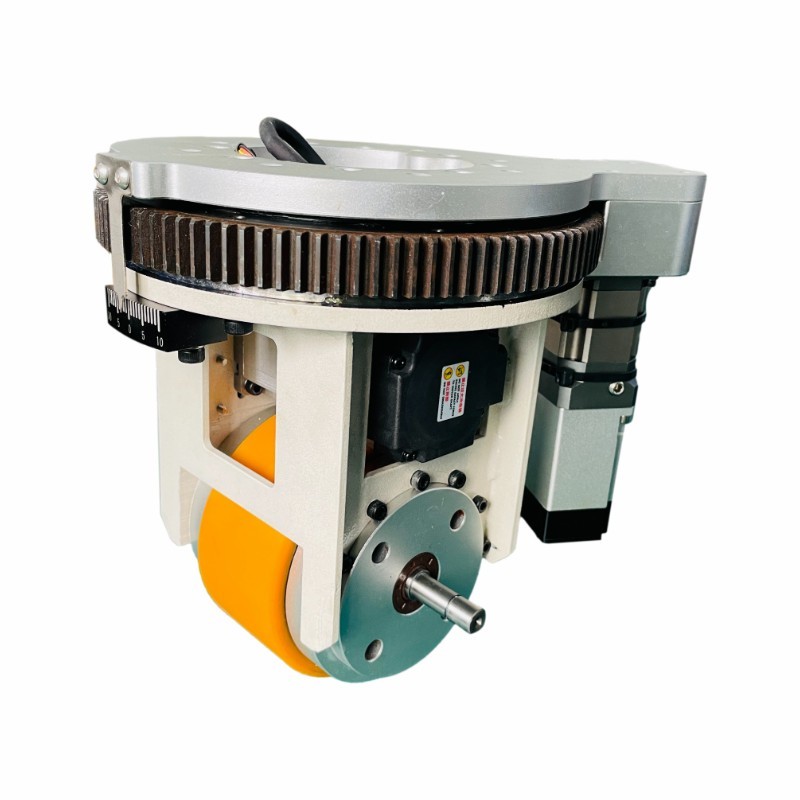

A vertical type motor drive wheel is a specific configuration of a drive wheel system where the motor is mounted vertically in relation to the wheel. This design is often used in applications such as Automated Guided Vehicles (AGVs), where space efficiency and design requirements may necessitate a more compact and integrated drive system.

Technical Parameter

Model ZL-V245 Gearbox Level 1-3 planetary Speed ratio I 7-120 Wheel diameter mm 125 Fastest speed m/min 20-90 Temperature ℃ -10 to +55 Weight KG about 25 Traction motor technical parameter Motor type Servo / Brushless Rated power W 200-2000 Rated voltage V DC24-110V / AC220-380V Rated speed rpm/min 3000 Rated Wheell torque N.m 60-120 Steering motor technical parameter Motor type Servo / Brushless Rated power W 100 - 400 Rated voltage V DC24-110V / AC220-380V Rated speed rpm/min 3000 Rated torque N.m 0.32-1.39 Steering reducer speed ratio I 35-120

Key Features

1. **Space-Saving Design**: The vertical orientation of the motor allows for a more compact design, which is beneficial in environments where space is at a premium. This design can lead to a lower overall profile for the vehicle, improving its ability to navigate under obstacles and in tight spaces.

2. **Integrated Motor and Wheel**: In this configuration, the motor is often integrated directly with the wheel, which can simplify the vehicle's design and reduce the number of components needed. This integration can also improve efficiency by reducing power loss due to shorter transmission distances.

3. **Efficient Power Transmission**: With the motor positioned vertically, the power transmission to the wheel is often more direct, which can result in higher efficiency and better torque delivery to the wheel. This is particularly important for AGVs that need to move heavy loads or maneuver in tight areas.

4. **Ease of Maintenance**: The vertical motor drive wheel setup can be designed for easy access, which simplifies maintenance and repair procedures. This is a significant advantage in industrial settings where downtime needs to be minimized.

Application Scenarios

- **Automated Guided Vehicles (AGVs)**: Vertical type motor drive wheels are commonly used in AGVs, which are employed in manufacturing plants, warehouses, and logistics centers for the automated transport of goods. The compact design of these wheels allows AGVs to operate in areas with limited space and to move under conveyors or other overhead equipment.

- **Material Handling Equipment**: In material handling applications, such as forklifts or automated storage and retrieval systems (AS/RS), vertical motor drive wheels can provide the necessary maneuverability and space-saving benefits.

- **Specialized Vehicles**: Certain specialized vehicles, like those used in tight or low-clearance environments (e.g., mining or construction equipment), can benefit from the design advantages of vertical motor drive wheels.

Considerations

- **Heat Dissipation**: Vertically mounted motors may require careful heat management solutions due to their orientation, as heat generated by the motor can rise and potentially affect other components or the vehicle's electronics.

- **Motor Cooling**: Ensuring adequate cooling for the motor is crucial to prevent overheating and maintain performance. This might involve the use of specialized cooling systems or heat-resistant materials.

- **Drive Wheel Size and Weight**: The size and weight of the drive wheel assembly can impact the vehicle's overall design and performance. Engineers must balance the need for a robust drive system with the constraints of the application.

In summary, vertical type motor drive wheels offer a range of benefits for AGVs and other specialized vehicles, particularly in terms of space efficiency and power transmission. However, design considerations such as heat management and motor cooling must be carefully addressed to ensure reliable and efficient operation.

Previous

Related products

undefined

Products Message

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-18102686399

Jackson +8615012435018

Candy:+86 19396885135

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct